Precision Machining for Medical, Pharmaceutical & Laboratory Components

In the medical, pharmaceutical, chemical, and laboratory equipment sectors, component durability and dimensional accuracy are paramount. Whether for surgical instruments, diagnostic devices, pharmaceutical tooling, or laboratory machinery, precision-machined parts crafted from premium materials deliver performance, longevity, and safety.

Core Machining Capabilities & Materials

Multi-Axis CNC Milling, Turning & Grinding

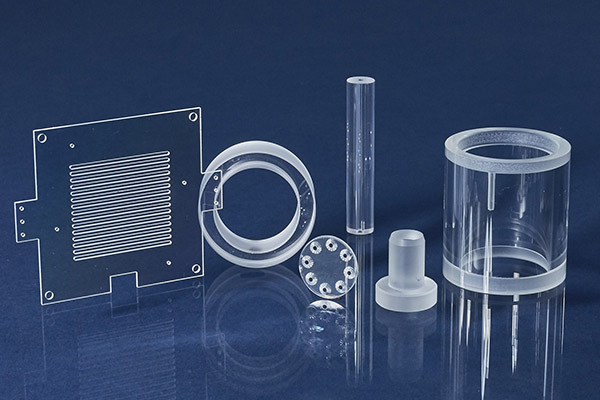

Advanced 3-axis, 4-axis, and 5-axis CNC machining, combined with precision grinding and honing—for structural parts, housings, dies, and tools in materials such as stainless steel, alloy steel, tool steel, aluminum, titanium, engineering plastics, hard carbide, technical ceramics, gemstones, and glass.

Meyer Industrial

Hard Material & Ceramic Tooling

Specialized manufacturing of tungsten carbide tooling and technical ceramic parts—including sintered carbide punches, tablet dies, ceramic inserts, laboratory vessel components, and sapphire/glass elements—optimized for wear-resistant applications in pharmaceutical pressing and catalyst carriers.

Gear, Spline & Transmission Part Fabrication

High-precision gear hobbing, milling, shaping, and grinding for critical gear components in medical automation, drive systems, and fluid dispensing mechanisms—using gear steel, nitrided steel, titanium, and high-temperature alloys.

EDM & Wire-Cut Machining

Spark EDM, wire EDM and mirror-finish strategies are employed for ultra-fine contours, small apertures, and sharp-edged components in hard or brittle materials used in medical and lab equipment.

Allen Tool Phoenix

Heat Treatment, Surface Finishing & Quality Control

Thermal Treatments

Vacuum quenching, oil quenching, solution treatment, gas nitriding, tempering, aging, and stress relief enhance wear resistance, toughness, and dimensional stability in critical components.

Surface Treatments

A range of precision finishes including anodizing, chemical conversion coating, passivation, electroless nickel plating, chrome plating, dry-film lubrication, etching, painting, and de-stress treatments—essential for corrosion resistance and cleanroom compatibility.

Non-Destructive Testing & Laboratory Inspection

Rigorous QA with X-ray, fluorescent penetrant inspection (FPI), magnetic particle inspection (MPI), material traceability, and precise dimensional reporting ensures reliability and safety certification.

Wikipedia

Applications in Medical, Pharma & Laboratory Fields

Medical Instruments & Surgical Tools: Precision structural parts and fittings for surgical devices and instrumentation.

Pharmaceutical Tablet Tooling: Tungsten carbide tablet punches and dies for high-cycle compression tooling.

Lab Equipment & Analysis Devices: Machined components for centrifuges, mixers, granulators, testing modules, and sampling systems.

Diagnostic & Patient Transfer Equipment: Lightweight aluminum/titanium housings, stainless and plastic structural parts, and precise valve bodies.

Implants & Prosthetics: Titanium alloy bone plates, fixation screws, implant bases, surgical implants, and orthopedic assemblies.

Eyecare & Hair Restoration Tools: Sapphire scalp blades, precision surgical pens, and capillary-based extraction heads tailored for FUE procedures.

Microfluidic Components & Valve Assemblies: Custom machined valves, injector tips, guide sleeves, and micro-scale fittings for medical fluid control systems.

SEO‑Focused Keywords

Incorporate these strategic keywords for strong search engine performance:

Medical component CNC machining

Pharmaceutical tooling engineering

Tungsten carbide tablet dies machining

Precision ceramic lab equipment parts

Sapphire surgical blade CNC precision

Cleanroom-grade stainless CNC components

Medical implant titanium machining

Microfluidic valve and injector machining

High-tolerance surgical instrument components

Gear & transmission parts for medical automation

Why Choose Precision Machined Medical & Laboratory Parts?

Superior Precision & Reliability: Critical for surgical, dosing, and diagnostic accuracy.

Exceptional Material Expertise: Machining carbide, technical ceramics, sapphire, high-grade alloys, and high-performance plastics.

Complete Production Workflow: From prototype through machining, heat treatment, finishing, and final inspection.

Scale from Prototype to Production: Agile support for both custom prototyping and high-volume instrument tooling.

Request a Custom Quote Today

If you have designs or specifications for medical instruments, pharmaceutical tooling, or laboratory device components, submit your files today. Receive a tailored proposal addressing machining strategy, materials guidance, tolerance planning, and optimized lifecycle performance.