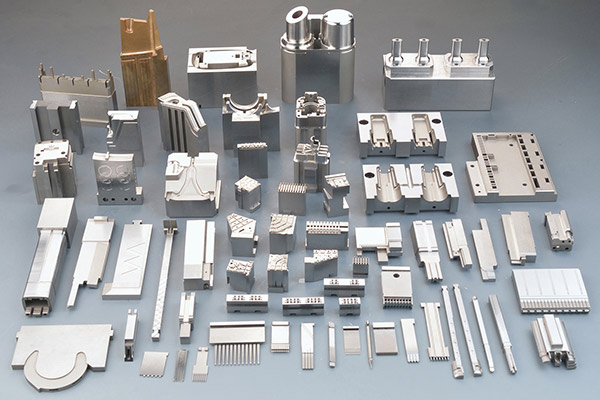

High-Precision Machining Services for Mold and Tooling Components

Precision molds and tooling components are essential for high-efficiency, high-output production in industries such as automotive, electronics, medical, packaging, and consumer goods. With advanced multi-axis CNC machining, EDM processing, and surface finishing technologies, we deliver mold components with tight tolerances, exceptional surface quality, and reliable service life.

Comprehensive Capabilities for Mold Machining

- Multi-Axis CNC Milling and Turning

Advanced 3-axis to 5-axis CNC machining ensures high accuracy for mold cores, cavities, inserts, sliders, lifters, and other complex mold components. Capable of handling intricate geometries, deep pockets, and compound angles. - High-Precision EDM and Wire Cutting

Spark EDM and slow-wire EDM processes produce complex contours, sharp corners, and tight internal features—ideal for cavity details, ejector slots, and precision mold inserts. - Surface and Cylindrical Grinding

Fine grinding for mold plates, guide pins, and hardened components. Ensures flatness, parallelism, and surface roughness suitable for high-performance tooling. - Custom Mold Base Machining

Machining of standardized or custom mold bases for plastic injection molds, die-casting molds, stamping dies, and progressive molds with precise alignment and durability.

Materials Machined for Mold & Tooling Components

- Tool steel (H13, S136, SKD61, P20, etc.)

- Alloy steel and stainless steel

- Tungsten carbide and hardened tool steels

- Copper, brass, and high-conductivity alloys for electrodes

- Engineering plastics and composite materials for prototype tooling

Typical Components and Applications

- Plastic Injection Mold Components: Core and cavity blocks, sliders, lifters, gates, hot runner plates, nozzle seats, and cooling inserts.

- Die-Casting Mold Parts: Ejector pins, bushings, wear plates, cooling elements, and thermal insulation components.

- Progressive Die Tooling: Punches, die plates, guide rails, stripper plates, and cams for high-speed stamping.

- Mold Repair & Custom Inserts: Precision inserts for mold maintenance or performance upgrades.

- Precision Electrodes: Copper and graphite electrodes for EDM machining of mold cavities and micro-features.

Value-Added Features

- Ultra-Tight Tolerances

Dimensional tolerances down to ±0.002 mm and flatness control for sealing and alignment surfaces. - Mirror Surface Finish

Optical-grade polishing and high-gloss finishes for transparent plastic parts or high-end cosmetic surfaces. - Integrated Thermal Treatment

Vacuum hardening, nitriding, tempering, and stress-relief processes for improved tool longevity and dimensional stability. - Cleanroom Assembly & Inspection

Optional clean environment for precision mold fitting, assembly, and quality inspection.

Target SEO Keywords

For effective search engine ranking, incorporate these keywords across page content and metadata:

- Precision mold component machining

- CNC machining for injection mold cores

- EDM machining for mold inserts

- Wire cut machining for stamping dies

- Mold base CNC manufacturing

- Die-casting mold parts machining

- Tool steel core cavity machining

- High-tolerance custom mold inserts

- Plastic injection mold component supplier

- Mold electrode machining services

Request a Custom Quote for Mold Components

Whether you’re developing a new mold project or upgrading tooling for higher production efficiency, we offer complete mold component machining services from prototype to mass production. Submit your drawings and specifications to receive a custom solution with precise tolerances, quality finishes, and rapid turnaround.