China CNC Machining Experts for High-Precision Global Projects

===INTRO:

In today’s global manufacturing landscape, the demand for high-precision CNC machining has soared, especially as industries such as aerospace, medical devices, defense, and high-tech electronics require increasingly complex and exact components. China has emerged as a powerhouse in this domain, boasting a multitude of CNC machining experts renowned for their craftsmanship, technological innovation, and ability to deliver tailored solutions. This article explores how China’s CNC machining specialists are setting new standards in precision and complexity, enabling global industries to turn intricate designs into reality with confidence and efficiency.

---

## China CNC Machining Experts: Delivering Precision for Global Industries

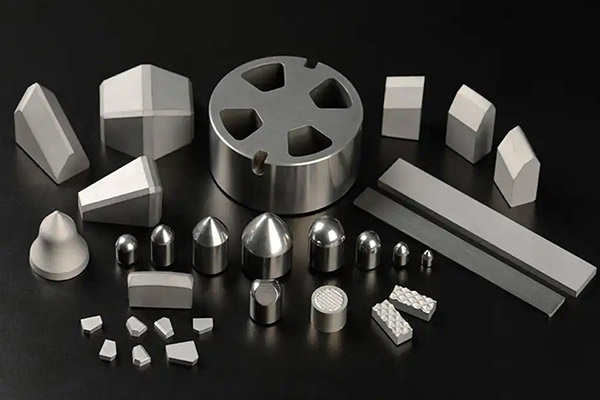

China's CNC machining industry has grown exponentially, supported by advanced manufacturing infrastructure, a vast talent pool, and continuous technological upgrades. These experts are adept at producing high-precision parts that meet strict international standards, making them reliable partners for global companies. Their expertise encompasses a broad spectrum of materials—from metals like titanium, stainless steel, and aluminum to high-performance composites—ensuring they can handle diverse project requirements.

One of the key strengths of Chinese CNC experts is their capacity to customize solutions based on client specifications. They meticulously interpret complex drawings and specifications, translating them into precise, functional components. This capability is crucial for industries such as aerospace and medical devices, where accuracy at the micron level can be critical. Their ability to maintain tight tolerances consistently builds trust among international clients.

Furthermore, Chinese CNC machining facilities are adopting cutting-edge technologies like multi-axis machining centers, automated inspection systems, and intelligent software solutions. These advancements facilitate complex geometries, multi-material integration, and rapid prototyping, enabling manufacturers to meet tight deadlines without sacrificing quality. As a result, Chinese CNC experts are recognized for their reliability in delivering complex components on time and within budget.

Another aspect that sets Chinese CNC machining apart is their emphasis on quality control. They implement rigorous inspection protocols throughout the manufacturing process, employing advanced measurement tools such as coordinate measuring machines (CMM) and 3D scanners. This thorough approach ensures each part adheres to the highest standards, reducing rework and enhancing overall product integrity.

In addition, many Chinese CNC providers are experienced in adhering to international standards such as ISO, ASME, and ASTM, which assures global clients of consistent quality and compliance. This international certification further cements their reputation as trusted suppliers capable of handling sensitive and high-precision projects.

Cost competitiveness is another notable advantage. Through optimized manufacturing processes and economies of scale, Chinese CNC machining experts can offer highly competitive prices without compromising quality—an attractive proposition for overseas clients seeking high-value solutions. Their ability to combine affordability with precision makes them a go-to choice for complex, high-stakes projects.

Lastly, the importance of communication and collaboration cannot be overlooked. Chinese CNC providers are increasingly adopting English communication channels, digital file management, and project tracking systems, ensuring seamless cooperation with international partners. This integration fosters transparency and efficiency across all project phases, from initial design to final delivery.

In summary, China’s CNC machining experts have established a formidable reputation for delivering high-precision, custom solutions on a global scale. Their technological prowess, material expertise, and rigorous quality standards position them as indispensable partners in advancing cutting-edge industries worldwide.

---

## Custom CNC Solutions: Turning Your Designs into Reality with High Precision

Custom CNC solutions are at the core of China’s machining industry, enabling clients to transform their complex designs into tangible components with unparalleled accuracy. Whether it’s a delicate medical implant, aerospace structural part, or intricate electronic housing, Chinese manufacturers excel at interpreting detailed drawings and specifications to produce precise, reliable parts.

The process begins with a comprehensive understanding of client requirements, including material selection, dimensional tolerances, surface finishes, and functional performance. Chinese CNC experts emphasize close collaboration during this phase, often providing technical consultation to optimize designs for manufacturability without compromising performance. This proactive approach minimizes production challenges and reduces costs.

Once the design is finalized, advanced CAD/CAM software is employed to generate optimized toolpaths for multi-axis CNC machines. This technology allows for the creation of complex geometries, internal channels, and fine surface details that traditional manufacturing methods struggle to achieve. Chinese manufacturers have invested heavily in such systems, making high-precision customization possible.

Material choice plays a crucial role in custom CNC solutions. Chinese experts are highly experienced in machining a wide array of materials—from high-strength alloys like Inconel and titanium to advanced ceramics and composites. Their understanding of the unique characteristics of each material ensures that the final component meets all functional and durability requirements.

Precision machining of high-hardness and difficult-to-machine materials is another area where Chinese specialists excel. They utilize specialized cutting tools, cooling techniques, and optimized machining parameters to achieve the desired tolerances and surface finishes. This level of expertise is essential for high-stakes industries where component failure is not an option.

Quality assurance is integral to custom CNC solutions. Chinese manufacturers implement rigorous inspection routines, including 3D scanning and coordinate measurement, to verify conformity with design specifications. This meticulous approach guarantees that every part delivered is within the tight tolerances required for high-precision applications.

Cost efficiency is a significant benefit of opting for custom CNC solutions in China. Through economies of scale, advanced automation, and skilled labor, Chinese providers can produce complex parts at competitive prices, making high-precision manufacturing accessible to a broader market. This affordability opens new opportunities for startups and established companies alike.

Speed-to-market is also a key advantage. With rapid prototyping capabilities, quick turnaround times, and flexible production lines, Chinese CNC experts facilitate fast realization of design iterations and pilot runs, accelerating product development cycles for global clients.

Furthermore, Chinese CNC machining experts are adept at handling batch productions ranging from small prototypes to large-volume manufacturing. Their scalable processes ensure consistent quality and precision across all production scales, fulfilling diverse client needs efficiently.

In essence, Chinese CNC providers turn intricate design concepts into high-precision, functional components tailored to specific industry demands. Their comprehensive approach—from design optimization to rigorous quality control—ensures that clients receive parts that meet and often exceed expectations, supporting innovation and competitiveness worldwide.

---

## Tackling Complex Materials and Challenging Projects with Expert Skill

One of the defining features of China’s CNC machining industry is its ability to handle complex materials and challenging projects that demand exceptional skill and experience. High-performance materials such as titanium, stainless steel, Inconel, and ceramics are frequently used in aerospace, medical, and defense sectors, requiring precise control over machining parameters and specialized tools.

Chinese experts have accumulated extensive experience working with these materials, understanding their unique behaviors during machining. For example, titanium and Inconel are notoriously difficult to machine due to their hardness and tendency to generate heat, which can cause deformation or tool wear. Chinese manufacturers employ advanced cooling techniques, optimized cutting speeds, and specialized tooling to mitigate these issues and achieve high precision.

Complex projects often involve tight tolerances, intricate geometries, and multi-material integrations. Chinese CNC machining experts are proficient in multi-axis machining, enabling the creation of complex internal features, curved surfaces, and fine details that are essential for functional and aesthetic purposes. Their capability to execute such challenging designs is supported by state-of-the-art equipment and skilled operators.

High-precision projects also demand strict adherence to quality standards and comprehensive inspection processes. Chinese manufacturers incorporate advanced metrology tools like 3D laser scanners and coordinate measuring machines to verify every detail against design specifications. This rigorous quality control ensures that even the most complex parts meet demanding industry requirements.

Handling difficult materials and complex geometries requires innovation and problem-solving skills. Chinese experts often develop customized toolpaths, select appropriate cutting tools, and implement unique machining strategies to overcome material-specific challenges. Their adaptability and expertise are crucial in producing parts that must withstand extreme conditions, such as high temperatures, corrosive environments, or mechanical stress.

In addition, some projects involve high-value or sensitive components, like medical implants or aerospace parts, where failure is not an option. Chinese CNC providers are experienced in implementing contamination control, cleanroom procedures, and traceability systems to ensure the integrity of these challenging projects.

Training and continuous learning are vital components of their skill set. Chinese technicians stay abreast of the latest advancements in materials science and machining technology, regularly updating their techniques to handle new and emerging materials. This ongoing professional development is key to maintaining their competitive edge.

Collaborating with clients to address unique project challenges is a hallmark of Chinese CNC experts. They often provide innovative solutions, including custom-fixture design, specialized tooling, and process adjustments, to ensure successful results despite the project’s complexity.

Finally, the ability to deliver high-precision, complex components consistently enhances China’s reputation in critical industries worldwide. Their proven track record in tackling tough materials and intricate designs underscores their position as global leaders capable of transforming even the most challenging ideas into reality.

---

## Case Studies: Overcoming Global CNC Machining Challenges with Proven Expertise

Several case studies highlight how China’s CNC machining experts have successfully addressed complex, high-precision manufacturing challenges on the global stage. These examples showcase their technical proficiency, problem-solving capabilities, and commitment to quality.

One notable case involved the production of high-precision aerospace components made from titanium. The client required parts with extremely tight tolerances and flawless surface finishes. Chinese experts utilized multi-axis machining centers, advanced cooling techniques, and rigorous quality controls, successfully delivering parts that met all specifications. This project underscored their ability to handle difficult materials and demanding standards.

Another case focused on medical device manufacturing, where intricate, high-precision components were required from advanced ceramics. The Chinese manufacturer developed specialized tooling and machining parameters to achieve the necessary accuracy while minimizing material stress. Their attention to detail ensured the safety, reliability, and functionality of the medical implants, reinforcing their reputation in the healthcare industry.

A particularly challenging project involved complex internal channels in electronic housings made from stainless steel. The Chinese team employed 5-axis machining and innovative fixture designs to access difficult geometries. The successful completion of this project demonstrated their capability to produce sophisticated parts with internal features that are typically hard to machine.

In the defense sector, Chinese CNC experts were tasked with manufacturing high-tolerance components from hardened steels for military applications. They utilized specialized cutting tools, heat management, and precision measurement systems to ensure durability and accuracy. Their ability to deliver consistent quality under stringent conditions proved their mastery in handling challenging applications.

Another case involved batch production of components with high surface quality and dimensional stability for the automotive sector. The Chinese manufacturer optimized their production processes, implemented automation, and maintained rigorous inspection routines, achieving high-volume output with minimal defects. This case highlights their scalability and consistency in high-precision manufacturing.

Throughout these projects, communication and seamless collaboration with international clients played a vital role. Chinese experts provided detailed updates, real-time problem-solving, and flexible adjustments, ensuring project success. Their proven expertise in overcoming global manufacturing challenges solidifies their position as trusted partners worldwide.

These case studies exemplify how Chinese CNC machining specialists leverage their technological innovations, extensive experience, and meticulous quality standards to solve some of the most demanding manufacturing puzzles. Their ability to deliver excellence across diverse industries underscores their significance in advancing high-precision global projects.

---

### China’s CNC machining industry has established itself as a leader in delivering high-precision, customized solutions globally. Their expertise in handling complex materials, intricate designs, and challenging engineering problems makes them an invaluable resource for industries that demand excellence. As technology continues to evolve, Chinese CNC experts are poised to maintain their edge by embracing innovation, enhancing quality standards, and fostering closer international collaborations—ensuring they remain at the forefront of high-precision manufacturing worldwide.