Industrial Sapphire Parts Customization Expert in CNC Machining

The Rising Demand for Ultra-Hard Precision Components

In high-tech industries where extreme durability, thermal resistance, and optical clarity are essential, industrial sapphire has emerged as one of the most advanced engineering materials. From semiconductor manufacturing and aerospace sensors to medical devices and fluid metering systems, sapphire components are crucial in environments where metals, plastics, and even ceramics fail.

As an experienced industrial sapphire parts customization expert, we offer tailored CNC machining solutions for precision sapphire components, enabling customers to meet demanding specifications in terms of dimensional accuracy, surface integrity, and functional performance.

Machining Challenges and Technical Solutions

Sapphire, a single-crystal form of aluminum oxide (Al₂O₃), ranks 9 on the Mohs hardness scale—just below diamond. This exceptional hardness, while ideal for wear resistance, makes sapphire one of the most difficult materials to machine.

Challenges in sapphire machining include:

- Tool wear and brittleness: Traditional cutting tools are ineffective; diamond tooling is required to avoid chipping and microfractures.

- Precision without cracking: Even minimal mechanical or thermal stress can cause breakage.

- Surface finish and transparency: Many applications require both dimensional accuracy and high optical clarity or flawless surfaces.

- Complex geometries: Micro-holes, slots, and custom edge radii must be machined without inducing subsurface damage.

Our technical solutions:

- Ultraprecision diamond grinding and CNC micromachining for accurate shaping of both flat and curved surfaces.

- Laser micromachining and ultrasonic-assisted machining to produce complex features without physical stress.

- Specialized fixturing and low-stress workholding to protect fragile parts during processing.

- Polishing and lapping to achieve Ra ≤ 0.01 μm surface roughness for optical-grade clarity.

By combining these advanced technologies, we ensure repeatable precision and long-term durability of every sapphire component we produce.

Common Sapphire Grades and Their Advantages

We offer machining services for a variety of synthetic sapphire grades, depending on application requirements:

- C-Plane (0001) Sapphire: The most common orientation for general use; excellent thermal conductivity and dielectric strength.

- A-Plane and R-Plane Sapphire: Used where anisotropic properties are needed, such as in optical or electronic alignment.

- Optical Grade Sapphire: High-transmission material used for IR windows, camera lenses, and sensor covers.

- Industrial Grade Sapphire: Cost-effective for mechanical applications like bearings, insulators, and wear pads.

All sapphire materials we use are sourced from qualified single-crystal manufacturers, and full traceability is provided on request.

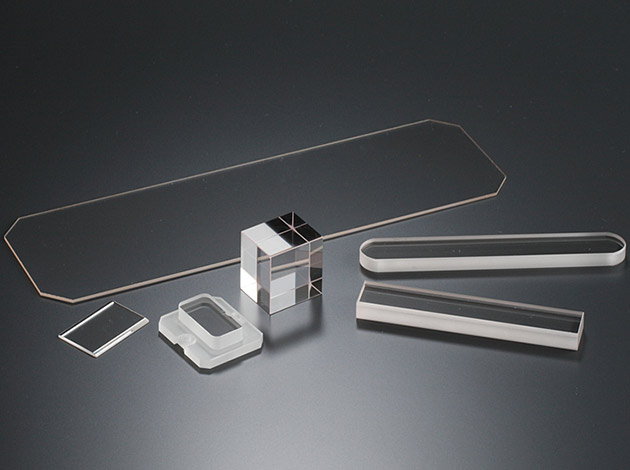

Advanced Machining Capabilities for Sapphire Parts

As a CNC machining expert for sapphire and other ultra-hard materials, we operate with a focus on high-precision, low-defect manufacturing:

- Dimensional Tolerances: Down to ±0.002 mm for precision fits and functional interfaces

- Surface Finish: Ra ≤ 0.01 μm with optional optical polishing

- Component Size Range: From micro-components (<2 mm) to plates or tubes up to 200 mm

- Available Processes: CNC diamond grinding, ultrasonic machining, micro-drilling, lapping, wafer slicing, laser cutting

- Geometry Support: Cylindrical, rectangular, conical, domed, slotted, through-hole, and ultra-thin profiles

Inspection & Quality Control

- Non-contact metrology systems to verify dimensions without scratching or damaging the part

- Interferometry and profilometry for optical surface analysis

- CMM and roundness testers with micron-level accuracy

- Full inspection documentation available, including COC, measurement reports, and material trace

Typical Components and Industrial Applications

We manufacture custom sapphire components for the most demanding applications:

- Semiconductor Equipment: Sapphire windows, alignment wafers, insulators, and substrate carriers

- Medical Devices: Surgical lens covers, fiber optic guides, fluidic orifices

- Industrial Sensors: IR-transparent windows, pressure sensor diaphragms, scratch-resistant lens covers

- Aerospace & Defense: Dome lenses, high-speed optical windows, sensor housings

- Precision Instruments: Sapphire bearings, styluses, micro-valves, nozzle tips

Each part is customized based on your drawing or CAD model, and we also offer reverse engineering of legacy sapphire components.

Case Study: Sapphire Flow Restrictor for Precision Fluid Metering

A recent project involved a custom sapphire orifice plate for a high-precision medical dosing system:

- Orifice Diameter: 0.15 mm ±0.005 mm

- Material: Optical-grade C-plane sapphire

- Finish: Ra ≤ 0.02 μm

- Inspection: Optical measurement, pressure test, laser diameter verification

The part achieved superior chemical resistance and dimensional stability, operating successfully under continuous flow and sterilization cycles without degradation.

Partner With a Trusted Sapphire CNC Machining Expert

If your application demands extreme wear resistance, optical clarity, or precise geometry in ultra-hard materials, our team is your ideal partner. As an industrial sapphire parts customization expert, we combine deep material knowledge with cutting-edge CNC machining technologies to deliver components that perform under the harshest conditions.

► Request a Quote Today — Precision Sapphire Components Engineered to Your Specs.