Rapid Prototyping Manufacturing with 3D Printing Technology + CNC Machining

Accelerating Innovation with High-Precision Prototypes

In today’s competitive product development environment, speed, accuracy, and adaptability are critical. Industries such as aerospace, automotive, medical devices, electronics, and consumer products require rapid iterations during the development phase without compromising on part quality. This is where rapid prototyping manufacturing with 3D printing technology + CNC machining becomes a strategic solution.

By integrating the speed and design freedom of 3D printing with the precision and surface finish of CNC machining, manufacturers can bring concepts to life faster, validate designs quickly, and reduce time-to-market—while achieving tight tolerances and functional performance close to that of mass-produced parts.

Challenges in Prototyping and How We Solve Them

Traditional prototyping methods often fall short when projects demand fast turnaround, high complexity, and functional integrity:

- Long lead times for tooling or molds increase development cycles.

- Inaccurate or weak prototype materials may not represent final production behavior.

- Lack of geometric flexibility restricts creativity and innovation.

- High costs associated with small-batch or single-piece production.

Our hybrid approach addresses these challenges with a blend of additive and subtractive technologies:

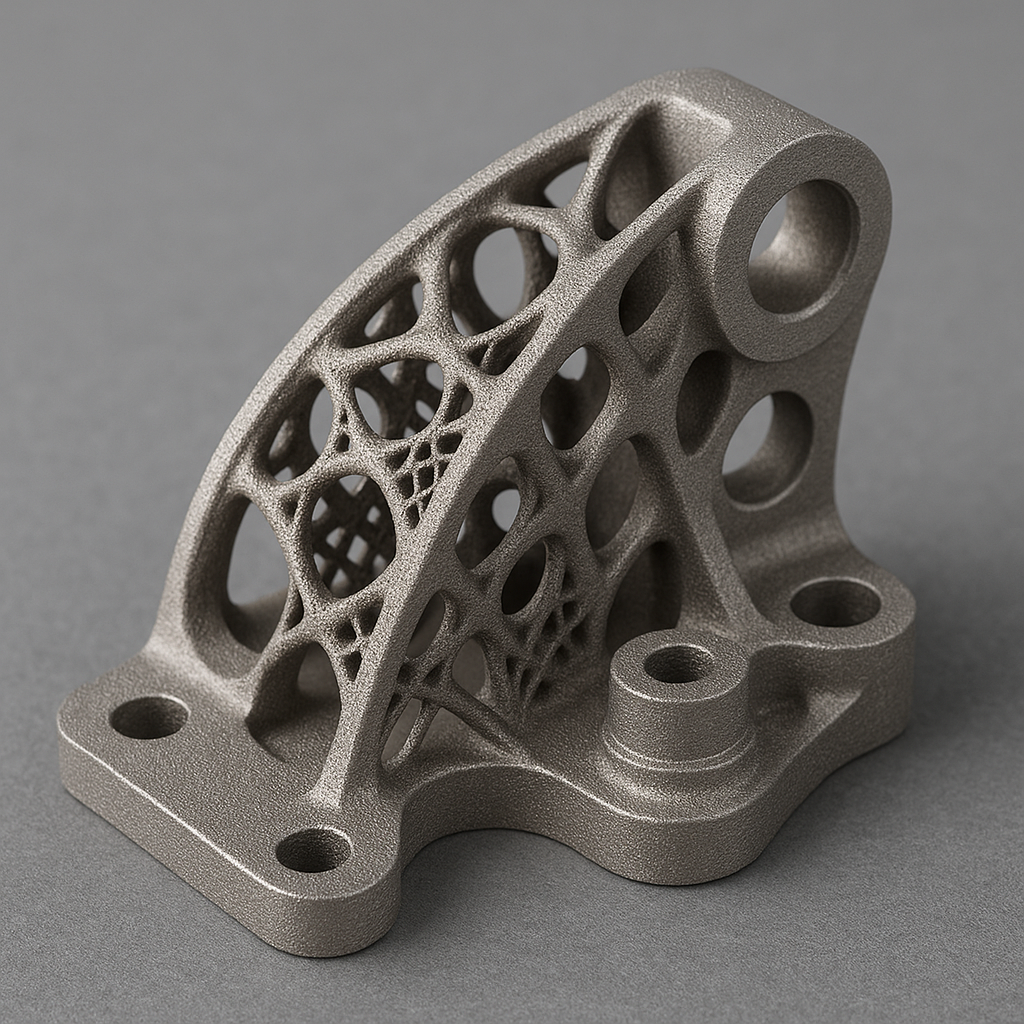

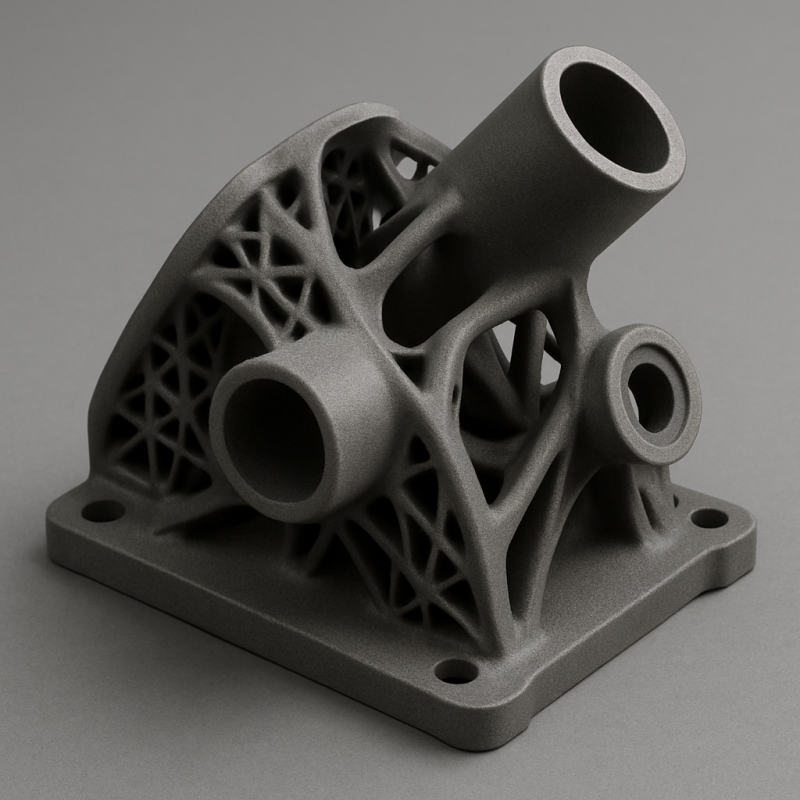

- 3D printing (SLA, SLS, MJF, FDM, DLP) is used to quickly create near-net-shape parts with internal channels, complex geometries, or lightweight structures.

- CNC machining is applied to critical surfaces, interfaces, or toleranced features to ensure proper fit and finish.

- Post-processing options such as surface polishing, painting, electroplating, or silicone molding offer functional and aesthetic enhancements.

- Design for manufacturability (DFM) review ensures your prototype transitions smoothly into production.

This combination allows us to deliver functional prototypes that accurately reflect real-world usage conditions—fast, affordably, and with precision.

Common Materials and Their Functional Benefits

We offer a wide variety of engineering-grade materials suitable for both 3D printed and CNC-machined prototypes, chosen based on application, mechanical requirements, and surface finish needs:

For 3D Printing:

- Resin (SLA/DLP): Ideal for visual models, master patterns, or medical mockups with high resolution and fine detail.

- Nylon (PA12/PA11 via SLS or MJF): Durable, impact-resistant, and heat-tolerant; used for functional testing parts and housings.

- TPU / TPE (Rubber-like): Excellent for gaskets, seals, and ergonomic grips requiring flexibility.

- ABS / PLA / PETG (FDM): Low-cost plastics for early-stage design iterations or large-format mockups.

For CNC Machining:

- Aluminum (6061, 7075): Lightweight and easy to machine; used in automotive, aerospace, and enclosure prototypes.

- Stainless Steel (304, 316, 420): Strong and corrosion-resistant; ideal for medical, food-grade, or structural components.

- Brass / Copper: Excellent for electrical components and decorative finishes.

- Engineering Plastics (POM, PEEK, PC, PMMA): Ideal for bearing surfaces, clear parts, or chemical-resistant applications.

We assist clients in selecting the right material depending on heat resistance, mechanical strength, weight, finish, and budget.

CNC and 3D Printing Capabilities

As a leading provider of rapid prototyping manufacturing with 3D printing technology + CNC machining, we are equipped with advanced machinery and inspection systems to ensure every part meets its intended design purpose.

3D Printing Capabilities:

- SLA/DLP: Ultra-fine resolution for dental models, microfluidic chips, or transparent components.

- SLS/MJF: High-strength parts with isotropic mechanical properties, ideal for functional prototypes.

- FDM: Low-cost and scalable for large parts and early-stage testing.

- Build Size: Up to 500 × 500 × 500 mm for a single part, with larger assemblies supported.

CNC Machining Capabilities:

- Multi-axis CNC milling (3, 4, 5-axis) for complex geometries and critical surface finishes

- CNC turning for round or concentric parts with tight tolerances

- Tolerances: ±0.01 mm for general surfaces; ±0.002 mm for critical features

- Surface Finishes: Ra ≤ 0.2 μm for mirror polishing or Ra ≤ 0.05 μm on optical-grade faces

Inspection Equipment:

- CMMs, digital height gauges, 3D scanners, and surface profilers are used to verify tolerances, roundness, and flatness

- 3D CAD comparison reports for rapid iteration tracking and design validation

Common Prototype Applications

Our prototyping solutions support early-stage development, design verification, and pilot production across multiple industries:

- Consumer Electronics: Phone housings, wearable enclosures, connector blocks

- Medical Devices: Implant test models, handheld instrument casings, guide tubes

- Aerospace: Lightweight air ducts, cable routing channels, sensor brackets

- Automotive: Dashboard parts, fluid manifolds, HVAC controls

- Industrial Machinery: Custom gears, levers, control panels, end effectors

Whether you need visual prototypes, functional testing parts, or low-volume bridge production, our team can deliver parts with the required accuracy, speed, and consistency.

Project Example: Hybrid Prototype for Smart IoT Enclosure

We recently supported the development of a smart IoT sensor module for an industrial automation client:

- Design: Complex enclosure with internal ventilation channels and snap-fit covers

- Process: MJF 3D printing for housing, CNC machining for sensor mounting features

- Material: Nylon PA12 + Aluminum 6061 inserts

- Lead Time: 5 working days from CAD to finished prototype

- Post-processing: Sandblasting and custom color painting

The hybrid solution enabled rapid design validation and user testing before final mold investment.

Work With a Prototyping and CNC Machining Expert

If you’re developing a product and need a partner who can combine speed with manufacturing-grade precision, our integrated 3D printing + CNC machining workflow is the answer. As a rapid prototyping manufacturing and CNC machining expert, we turn ideas into tangible, functional components—fast, flexible, and ready for the real world.

👉 Request a Quote Today — Precision Prototypes, Delivered at Speed.