Aerospace and Defense Parts Custom Machining Expert – Precision CNC Machining Solutions for Demanding Applications

Introduction: Precision Requirements in the Aerospace & Defense Industry

The aerospace and defense industries demand extreme precision, exceptional reliability, and tight manufacturing tolerances. From flight-critical aircraft components to high-performance defense systems, every part must meet rigorous standards for functionality, safety, and durability. As an aerospace and defense parts custom machining expert, our CNC machining solutions are engineered to deliver unmatched accuracy and consistency across complex geometries and high-performance materials.

In these industries, a single micron can be the difference between mission success and failure. That’s why precision CNC machining is not just a choice—it’s a necessity.

Machining Challenges and Our Solutions

High-Performance Materials:

Aerospace and defense components often involve hard-to-machine materials such as titanium alloys, Inconel, stainless steel, and high-performance ceramics. These materials are chosen for their strength-to-weight ratios, thermal resistance, and corrosion resistance—but they present significant challenges in cutting, wear, and thermal distortion.

Tight Tolerances:

Parts used in aircraft engines, navigation systems, and weapons platforms typically require tolerances as tight as ±0.001mm. Meeting these tolerances across batches without deviations requires advanced equipment and seasoned expertise.

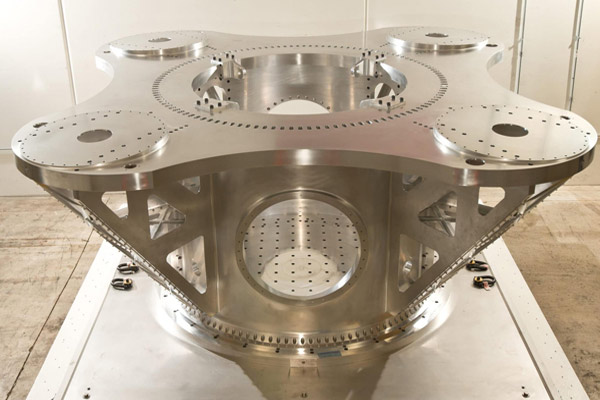

Complex Geometries:

Designs often involve multi-surface contours, internal channels, and asymmetric features that demand simultaneous multi-axis machining and advanced toolpath strategies.

Solution:

We overcome these challenges using high-precision 5-axis and 4-axis CNC machining centers, optimized CAM programming, and strict process control. Our engineering team collaborates with clients from the design stage to ensure DFM (Design for Manufacturability), and our quality assurance protocols ensure each part meets the required specification with full documentation and traceability.

Commonly Used Materials and Their Characteristics

To support the unique demands of aerospace and defense applications, we work with a broad range of materials:

- Titanium Alloys (e.g., Ti-6Al-4V): High strength, low density, corrosion resistance, ideal for engine parts and structural components.

- Aluminum Alloys (e.g., 7075, 6061): Lightweight, excellent machinability, commonly used in airframes, housings, and mounts.

- Stainless Steel (e.g., 17-4PH, 304, 316): Excellent corrosion resistance and strength for load-bearing or high-temperature environments.

- Inconel (e.g., 718): Superior thermal and chemical resistance, used in turbine components and exhaust systems.

- PEEK and Engineering Plastics: Used in insulation parts and lightweight internal fixtures.

- Ceramics and Sapphire: For high-wear or extreme thermal insulation components in optical or radar systems.

Each material is selected based on its role in the application, and our CNC process is adjusted accordingly for optimal results.

CNC Machining Capabilities

As a dedicated aerospace and defense parts custom machining expert, our capabilities include:

- Tolerance Control: We maintain dimensional tolerances down to ±0.001mm and geometrical tolerances (flatness, roundness, concentricity) within 0.002mm.

- Surface Finish: Achievable roughness as low as Ra 0.02μm for critical sealing or interface surfaces.

- Precision Equipment:

- Mazak CNC Lathes – Ideal for high-speed, precision rough turning.

- Mikron CNC Milling Centers – Optimized for complex profiles and fine-detail milling.

- Studer Cylindrical Grinders – For ultra-high accuracy shaft grinding.

- Zeiss CMM & Tokyo Seimitsu Roundness Tester – Ensures precision verification with full inspection reports.

- Advanced Processes: Multi-axis simultaneous machining, ultra-fine grinding, vacuum heat treatment coordination, and clean-room-level assembly when required.

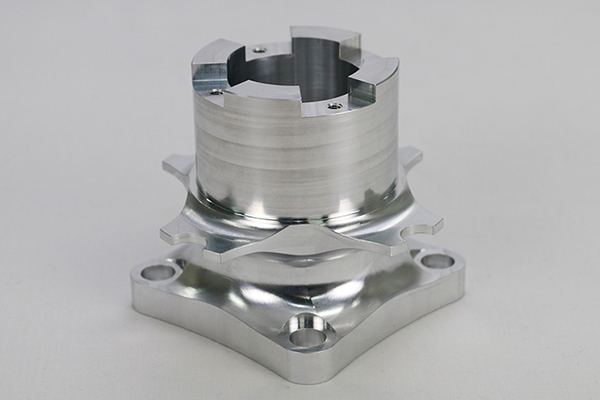

Common CNC Machined Parts & Applications

Our CNC machining services cover a wide array of parts used in aerospace and defense platforms:

- Aircraft Structural Components: Brackets, ribs, support frames machined from aluminum and titanium.

- Engine Parts: Turbine discs, impellers, shafts, and housings made of Inconel and stainless steel.

- Landing Gear Components: Precision axle sleeves, bushing interfaces, and high-strength steel pins.

- Electronic Enclosures: Lightweight aluminum or PEEK-based housings for radar and communication systems.

- Defense Hardware: Mounting systems, optical holders, missile fin components, and UAV mechanical structures.

Each part is produced to conform with strict MIL-spec or AS9100/ISO standards, ensuring compatibility with demanding aerospace-grade expectations.

Project Example

One recent project involved the CNC precision machining of a titanium-grade camera gimbal bracket used in an airborne reconnaissance system. The part required 5-axis simultaneous milling, internal channeling for weight reduction, and surface finishing to Ra 0.03μm. We achieved all critical dimensions within ±0.002mm tolerance and delivered on schedule, complete with CMM inspection and material traceability certification.

Contact Us for Custom CNC Machining Projects

Whether you’re developing advanced aerospace systems, upgrading legacy defense equipment, or prototyping next-gen UAV components, precision and reliability are non-negotiable. As a trusted aerospace and defense parts custom machining expert, we provide end-to-end CNC machining solutions tailored to your exact specifications.

Get in touch today to discuss your next project or request a quote. Our engineers are ready to assist with technical consultation, material selection, and fast-turnaround prototyping.