Custom Automotive Parts CNC Machining – Precision Manufacturing for High-Performance Vehicles

Introduction: Precision Demands in the Automotive Industry

As the automotive industry rapidly evolves—driven by electrification, intelligent systems, and lightweighting—precision manufacturing has become more critical than ever. Whether in combustion engines, EV powertrains, transmission systems, or advanced driver assistance systems (ADAS), each component must meet strict performance standards and endure dynamic operational stress.

Manufacturers and OEM suppliers demand high-precision, reliable, and cost-effective solutions. Our expertise in custom automotive parts CNC machining (Customized auto parts as per drawing) ensures that your components are produced with exact tolerances, premium materials, and robust quality assurance—delivering consistency from prototyping to mass production.

Machining Challenges and Our Solutions

Automotive components face several engineering and manufacturing challenges:

- High Tolerance Requirements: Critical parts such as shafts, gears, and housings must maintain tolerances often within ±0.001mm to ensure smooth power transmission and minimize vibration or noise.

- Complex Multi-Surface Geometry: EV motor components, combustion engine valves, and transmission housings involve intricate internal and external profiles requiring simultaneous multi-axis CNC machining.

- Volume and Repeatability: The automotive sector often requires medium- to high-volume production runs with strict repeatability and traceability for every part.

- Material-Specific Machining Difficulties: Aluminum, hardened steel, and composite materials pose different challenges for tool wear, thermal stability, and dimensional control.

Our Solution:

We deploy a comprehensive CNC workflow, combining high-speed milling, multi-axis turning, fine grinding, and automated inspection. Our digital process control ensures stable output, while our tooling strategies and fixture designs enable both low- and high-volume flexibility.

Common Materials and Their Characteristics

The choice of material is crucial for automotive performance, weight reduction, and cost control. We work with a wide range of materials tailored to specific functions:

- Aluminum Alloys (e.g., 6061, 7075, ADC12): Lightweight and thermally conductive, widely used in housings, battery trays, and EV motor frames.

- Alloy Steels (e.g., 20CrMnTi, 42CrMo): High fatigue strength, used for gears, shafts, and differential components.

- Stainless Steel (e.g., 304, 316, 17-4PH): Corrosion-resistant for exhaust components, fasteners, and sensors.

- Carbon Steel (e.g., C45, S50C): Cost-effective and strong, ideal for chassis brackets and suspension parts.

- Copper and Brass: Excellent conductivity for electronic and thermal management components.

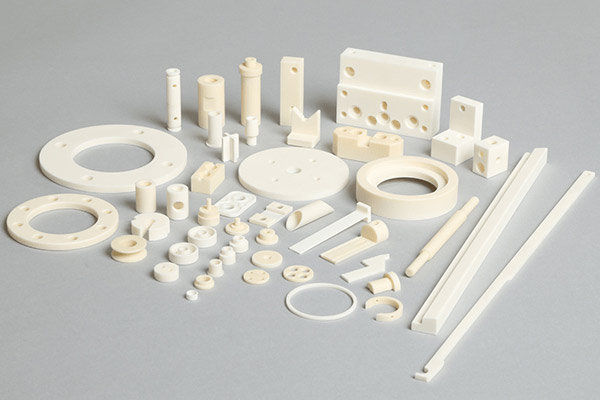

- Engineering Plastics (e.g., POM, PA6, PEEK): Used in lightweight structural parts, fluid connectors, and bushings.

Each material is selected based on application-specific requirements, and our CNC machining parameters are fine-tuned to ensure dimensional accuracy, surface finish, and mechanical integrity.

CNC Machining Capabilities

Our facility is equipped with advanced CNC machining technologies that support rapid prototyping and full-scale production of Customized auto parts as per drawing:

- Precision Machining Capabilities:

- Tolerances: ±0.001mm on critical dimensions

- Surface Finish: Ra 0.2μm to Ra 0.02μm, depending on sealing or wear surface requirements

- Roundness & Concentricity: Controlled within 0.002mm for shaft and rotating elements

- Key Equipment:

- Mazak CNC Lathes – For shaft and cylindrical component machining

- Mikron High-Speed Milling Centers – Ideal for EV and engine housing profiles

- Studer Cylindrical Grinders – For ultra-precision OD/ID grinding

- Zeiss CMM & Tokyo Seimitsu Roundness Testers – Ensure precise inspection and form verification

- Production Flexibility:

- Low-volume prototyping for early-stage development

- High-volume production with automated workholding and quality tracking

- Just-in-time scheduling to align with automotive assembly timelines

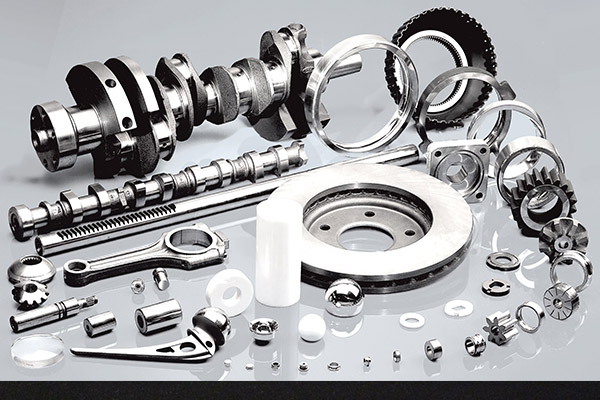

Common CNC Machined Automotive Parts & Their Applications

We specialize in CNC machining a wide variety of custom automotive components (Customized auto parts as per drawing) used in both traditional ICE and modern EV platforms:

- Drive Shafts and Axles: For torque transmission in engine and electric drive systems

- Motor End Covers and Housings: For EV stators and battery enclosures

- Gears, Sprockets, and Transmission Rings: For high-efficiency mechanical transmission

- Valve Seats, Spools, and Rocker Arms: Critical engine and fuel system components

- Sensor Housings and Mounting Brackets: Used in safety and control modules (ADAS, ESC, ABS)

- Aluminum Heat Sinks and Cooling Plates: For thermal management in EV battery and controller systems

- Brake Caliper Parts and ABS Valve Bodies: Precision machined under high safety standards

Our expertise covers passenger cars, commercial vehicles, new energy vehicles, and performance tuning components.

Project Highlight

One recent success involved the precision CNC machining of 7075-T6 aluminum motor housings for a high-performance electric vehicle. These components required 5-axis machining, controlled surface flatness within 0.01mm, and Ra 0.4μm finish on mating surfaces. By optimizing cutting strategies and employing in-line inspection, we ensured consistent batch delivery with zero non-conformities across thousands of parts.

Let’s Build the Future of Mobility — Together

From ICE engine parts to EV thermal solutions, our CNC machining services are tailored for performance, reliability, and precision. As a trusted partner in custom automotive parts CNC machining (Customized auto parts as per drawing), we help manufacturers stay ahead in a competitive and fast-changing market.

Contact us today for a quote or to discuss your technical drawings. Whether you’re in R&D prototyping or ramping up full production, our engineering team is ready to deliver the precision your automotive project demands.