Custom Energy Sector Parts CNC Machining – Precision Components for Power Generation, Transmission, and Sustainability

Introduction: Precision Demands in the Energy Sector

As the global demand for reliable and sustainable energy intensifies, the performance expectations for components used in energy generation, transmission, and storage have become increasingly strict. Whether supporting wind turbines, solar power systems, oil & gas extraction, nuclear power facilities, or grid infrastructure, energy equipment must operate continuously in extreme environments with zero room for error.

At the core of every high-performance system are components that require exceptional durability, thermal stability, and dimensional precision. As a custom energy sector parts CNC machining provider, we offer high-precision manufacturing services tailored to meet the rigorous standards of both conventional and renewable energy industries.

Machining Challenges and Our Solutions

Energy sector components face a unique set of machining and operational challenges:

- Large and Heavy Parts with Tight Tolerances: Many parts, such as turbine shafts or generator housings, are large in size and weight, but still require micron-level accuracy.

- Harsh Environments: Components must endure extreme temperatures, pressure fluctuations, corrosion from fluids or chemicals, and long-term fatigue loads.

- Material Hardness and Machinability: Superalloys, hardened steels, and heat-resistant materials are common in energy equipment, requiring specialized tooling, coolant strategies, and cutting speeds.

- Complex Geometries and Function-Integrated Designs: Energy system designs increasingly demand multi-functional parts with internal channels, intricate sealing surfaces, and custom threads or ports.

Our Solution:

We utilize a blend of high-precision 5-axis and 4-axis CNC machining, deep-hole drilling, and advanced grinding to meet these challenges head-on. From roughing to final inspection, our entire process is designed for high repeatability, tight tolerances, and certified material traceability—ensuring your custom energy parts are built to last in the world’s toughest operating environments.

Commonly Used Materials and Their Characteristics

The choice of material plays a crucial role in the safety, durability, and efficiency of energy equipment. We work with a wide range of materials optimized for different sub-sectors of the energy industry:

- Inconel (718, 625): Exceptional resistance to heat and corrosion, ideal for turbine blades, valves, and exhaust systems.

- Stainless Steel (304, 316, 410, 17-4PH): Used in both offshore and onshore energy applications due to corrosion resistance and structural integrity.

- Alloy Steel (42CrMo, 20CrNiMo): High strength and fatigue resistance, often used in shafts, gearboxes, and pressure components.

- Carbon Steel (Q235, Q345): Cost-effective and weldable, used for large structural components and mounting frames.

- Aluminum Alloys (6061, 7075): Lightweight and corrosion-resistant for control boxes, enclosures, and solar mounting systems.

- Copper and Brass: Excellent conductivity for grounding, connectors, and heat exchangers in power transmission.

- Engineering Plastics (PEEK, PTFE): High-temperature and chemical-resistant polymers used in insulation and sealing components.

Each material is matched with optimized cutting parameters and post-processing treatments (such as heat treatment or coating) to maximize part performance and longevity.

CNC Machining Capabilities

As a trusted manufacturer of custom energy sector parts, we offer a full suite of CNC machining solutions designed to meet the highest industry standards.

- Precision Tolerances:

- Dimensional accuracy down to ±0.001mm

- Roundness and concentricity controlled within 0.002mm

- Surface finishes up to Ra 0.02μm on sealing or mating areas

- Advanced Equipment:

- Mazak CNC Lathes – Ideal for turning large shafts, connectors, and flanges

- Mikron High-Speed CNC Milling Centers – For intricate geometries and high surface quality

- Studer Cylindrical Grinders – For precision OD/ID grinding of rotating and sealing parts

- Zeiss CMMs & Roundness Measuring Systems – Ensure high-accuracy inspection and documentation

- Supplementary Capabilities:

- Heat treatment (nitriding, hardening, stress relief)

- Surface finishing (anodizing, black oxide, nickel plating)

- Ultrasonic cleaning and ISO-standard packaging for critical components

Our shop supports everything from rapid prototyping to medium- and large-batch production runs, with process traceability and QA reports provided as standard.

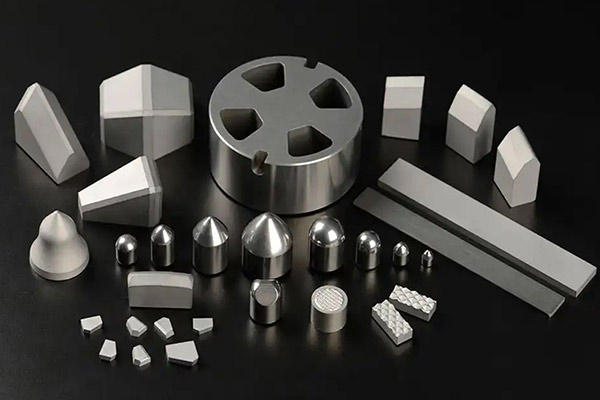

Typical CNC Machined Parts and Applications

We manufacture a diverse range of custom CNC machined components for the energy sector, covering applications in traditional power plants, oil & gas, and renewable energy systems:

- Turbine Shafts and Couplings: For steam, gas, hydro, and wind turbines

- Valve Bodies and Control Sleeves: For fluid control in pipelines and high-pressure systems

- Generator and Motor Housings: Machined from aluminum or castings, ensuring heat dissipation and strength

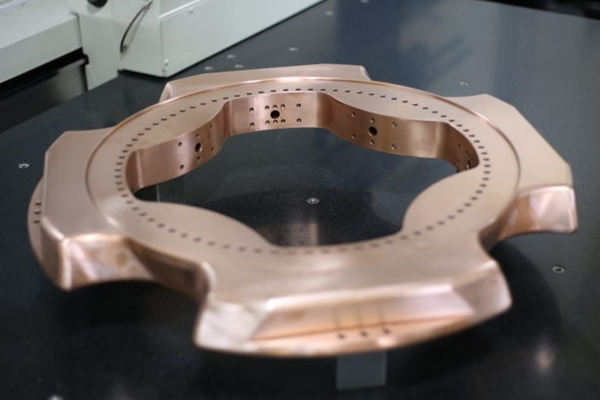

- Heat Exchanger Plates and Connectors: Precision-machined for thermal efficiency and fluid control

- Solar Tracker Components: Shafts, brackets, and supports requiring weather and UV resistance

- Insulated Bushings and Mounts: CNC-milled from high-performance engineering plastics

- Pump Casings and Sealing Rings: Used in both offshore oil extraction and inland hydropower stations

Every part is produced according to client-provided drawings or 3D CAD models and validated through a comprehensive inspection process.

Project Highlight

In a recent wind energy project, we produced a series of 4140 steel gearbox shafts for a 1.5MW wind turbine. These parts required turning, hardening, cylindrical grinding, and full CMM inspection. The project achieved concentricity within 0.003mm and surface finish of Ra 0.1μm, ensuring long-term operation with minimal maintenance in high-altitude, high-humidity environments.

Your Partner in Precision Energy Component Manufacturing

As global energy systems become more complex and diversified, the need for precision-engineered components becomes even more essential. Whether you are working on fossil fuel optimization, solar infrastructure, or wind energy transmission, we offer complete custom energy sector parts CNC machining services that match your technical demands and timeline.

Get in touch today to discuss your machining needs. Send us your drawings or project requirements—we’re ready to deliver precision components that keep your energy systems running reliably and efficiently.