Custom Engineering Machinery and Automation Equipment Parts CNC Machining – Precision for Industrial Performance

Introduction: Precision Requirements in Engineering Machinery and Automation

Modern industrial machinery and automation systems are built upon the foundation of high-precision components. From heavy-duty excavators and gantry cranes to robotic arms and CNC-based automation cells, every machine’s efficiency and reliability depend on the accuracy of its mechanical parts. These parts must withstand continuous loads, complex motion cycles, and demanding work environments.

As a specialist in custom engineering machinery and automation equipment parts CNC machining, we provide end-to-end machining solutions tailored to meet your performance, safety, and durability expectations. Whether it’s a single precision bracket or a large automation frame, we ensure your parts are built to spec—on time and to exacting standards.

Machining Challenges and Our Solutions

Components for industrial and automation machinery pose unique manufacturing challenges:

- High Precision Across Large Dimensions: Automation and engineering machinery components often have large physical dimensions, yet require ±0.01mm or better tolerances to ensure proper mechanical coordination.

- Complex Multi-Axis Geometry: Many parts feature keyways, grooves, threads, and ports that must align accurately across multiple faces, demanding 4-axis or 5-axis CNC machining strategies.

- Wear Resistance and Load Bearing: Parts like guide rails, linear blocks, and mounting brackets are subject to repeated motion, requiring high hardness and surface finish quality.

- Custom Design Adaptability: Automation components are often built to custom blueprints, with unique features that must be interpreted, simulated, and verified before manufacturing.

Our Solution:

We deploy a full workflow—from DFM (Design for Manufacturability) consultation to final inspection. With multi-axis machining centers, CNC grinders, and high-speed milling equipment, we can achieve tight tolerances, mirror-quality surface finishes, and reliable repeatability. Each part is produced based on customer-supplied drawings or 3D models, with proactive engineering input to optimize manufacturability and cost-efficiency.

Common Materials and Their Characteristics

To meet diverse engineering demands, we machine a wide variety of metals and engineering polymers suitable for both heavy-load and precision applications:

- Alloy Steel (e.g., 40Cr, 42CrMo, 20CrMnTi): High tensile strength and toughness, perfect for structural parts, gears, and rotating shafts.

- Carbon Steel (e.g., Q235, S45C): Good machinability and cost-effectiveness, used for frames, supports, and brackets.

- Stainless Steel (e.g., 304, 316, 17-4PH): Corrosion resistance and long service life, often used in automated food processing, packaging, and medical automation systems.

- Aluminum Alloys (e.g., 6061-T6, 7075): Lightweight, high strength-to-weight ratio, excellent for motion system brackets, robotic arm components, and enclosures.

- Brass and Bronze: Self-lubricating, corrosion-resistant, and ideal for bushings, bearings, and connectors.

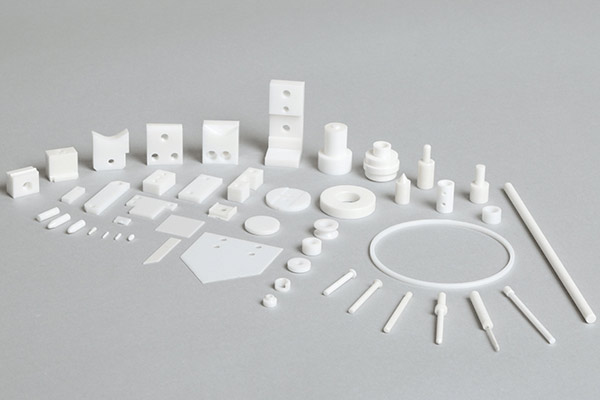

- Engineering Plastics (e.g., POM, PEEK, PTFE): Low-friction, high-durability materials for motion interfaces, sliding parts, and electrical insulation components.

Each material is selected according to the mechanical stress, environmental exposure, and motion dynamics of the application, with surface treatments applied where needed (e.g., hardening, anodizing, plating).

CNC Machining Capabilities

Our precision CNC machining capabilities support the complete life cycle of custom engineering machinery and automation equipment parts, from prototype to high-volume production:

- Tolerances & Surface Finishes:

- Dimensional tolerances: ±0.001mm

- Surface finish: Ra 0.2–0.02μm, ideal for sealing or motion-critical surfaces

- Roundness and straightness: Controlled within 0.002mm

- Machinery and Equipment:

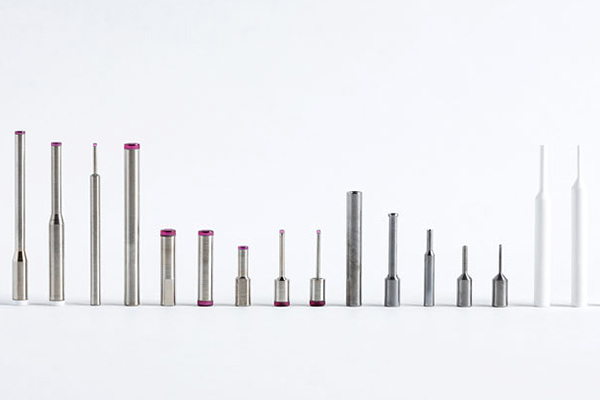

- Mazak CNC Lathes: High-speed, high-precision turning of shafts, pistons, and pins

- Mikron CNC Milling Centers: For complex contour and cavity machining in aluminum and steel

- Studer Cylindrical Grinders: Ultra-fine grinding for shafts, sleeves, and linear guide rails

- Zeiss CMM and Tokyo Seimitsu Roundness Measurement Systems: Ensure each part meets exact form and dimensional specs

- Support Capabilities:

- Heat treatment (carburizing, nitriding, quenching)

- Surface treatments (anodizing, black oxide, zinc plating)

- Ultrasonic cleaning, rust prevention, and customized packaging for global delivery

Every part undergoes rigorous inspection to ensure compliance with customer specifications and industry standards.

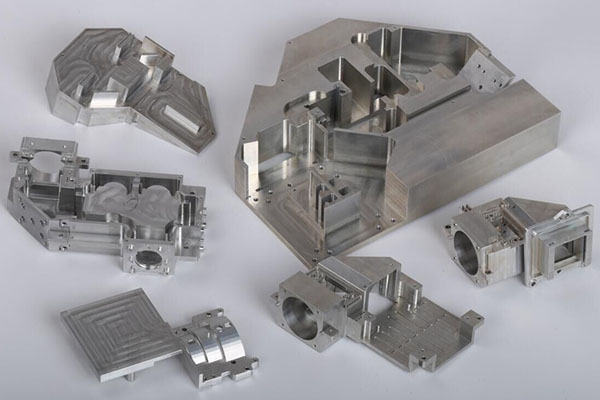

Typical CNC Machined Parts and Their Applications

We supply custom CNC machined parts for a wide range of machinery used across manufacturing, construction, logistics, packaging, and automation sectors:

- Guide Rails and Linear Shafts: For motion control in robotic arms and conveyor systems

- Brackets, Frames, and Mounting Bases: Provide structural integrity for heavy-duty machines

- Custom Gears and Sprockets: Transmit motion and force in industrial automation setups

- Precision Bushings and Wear Rings: With tight tolerances and special coatings for friction reduction

- Sensor Housings and Actuator Interfaces: Critical for robotic and sensor-controlled devices

- Clamping Jaws, End Effectors, and Fixtures: Custom automation tooling components

- Threaded Inserts, Couplings, and Rotors: For drive systems and motion modules

Each part is delivered with full traceability, material certification, and inspection reports, making them ready for direct integration into your machines.

Project Highlight

In one notable project, we delivered a batch of high-strength 42CrMo support arms for a robotic palletizing unit. The parts were milled and drilled on a 4-axis CNC center, then heat-treated and ground to achieve surface hardness of HRC 58 and dimensional accuracy within ±0.002mm. This ensured long service life and zero deformation under repeated robotic motion cycles.

Let’s Build Your Custom Mechanical Solution

Whether you’re designing a next-generation automation line or upgrading construction machinery for higher performance, our custom engineering machinery and automation equipment parts CNC machining services ensure every part is made to perform. From raw material to final inspection, we deliver precision, consistency, and quality you can count on.

Contact us today to request a quote, upload your part drawings, or speak with a CNC machining specialist. Let’s turn your mechanical designs into high-performance reality.