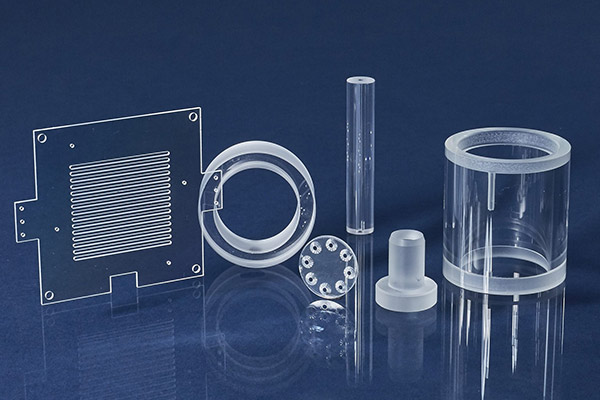

Custom Medical, Chemical, and Laboratory Parts CNC Machining – Ultra-Precise Components for Critical Applications

Introduction: The Need for Precision in Medical, Chemical, and Laboratory Equipment

In industries where lives, scientific integrity, and regulatory compliance are at stake, precision is not optional—it’s essential. Medical devices, analytical instruments, and chemical processing equipment rely on mechanical components that must perform flawlessly under strict hygiene, dimensional, and material standards.

Whether it’s a valve body for fluid delivery in a diagnostic analyzer, a titanium part for surgical equipment, or a chemically inert component for lab automation, these applications require the highest level of manufacturing precision. Our custom medical, chemical, and laboratory parts CNC machining services are designed to meet these exacting demands with certified materials, fine-tolerance machining, and full traceability.

Machining Challenges and Our Solutions

Parts used in medical and lab-related equipment present unique manufacturing challenges:

- Biocompatibility and Material Compliance: Medical and chemical environments demand materials that are non-reactive, corrosion-resistant, and often biocompatible (e.g., ISO 10993, USP Class VI).

- Ultra-Tight Tolerances: Components such as precision housings, pump rotors, or dosing heads require tolerances of ±0.001mm or better to ensure fit, function, and safety.

- Smooth, Cleanable Surface Finishes: Polished or passivated surfaces help prevent contamination and enable sterilization—essential for reusable medical and laboratory tools.

- Complex and Small-Scale Geometries: Miniaturized parts for lab automation or endoscopy devices require precision micro-machining and burr-free finishes.

Our Solution:

We provide end-to-end CNC machining solutions with capabilities tailored for critical medical, chemical, and laboratory applications. All production is done in clean, controlled environments with validated processes, including traceable material sourcing, process documentation, and rigorous final inspection.

Common Materials and Their Characteristics

We work with a wide range of certified materials suited for demanding environments involving human contact, sterile conditions, or aggressive chemicals:

- Stainless Steel (316L, 17-4PH, 303): Excellent corrosion resistance and biocompatibility, commonly used in surgical tools, dental devices, and lab fittings.

- Titanium (Grade 2, Grade 5): Lightweight, strong, and highly biocompatible—ideal for implantable devices, surgical instruments, and orthopedic components.

- PEEK (Polyether ether ketone): High-performance thermoplastic with outstanding chemical resistance and thermal stability, suitable for autoclave-sterilizable parts.

- PTFE, PVDF, and UHMWPE: Used for chemically inert components such as tubing connectors, seals, and pump components in laboratory automation.

- Aluminum Alloys (6061-T6, 7075): Lightweight and cost-effective, frequently used for housings, brackets, and fixtures that require anodized finishes.

- Brass and Bronze: For precise flow-control valves or quick-connect fittings in low-corrosive lab environments.

All materials can be certified per ASTM, ISO, or FDA compliance upon request. Surface treatments such as electropolishing, passivation, and anodizing can be applied to enhance cleanliness, corrosion resistance, or visual identification.

CNC Machining Capabilities

As a precision specialist in custom medical, chemical, and laboratory parts CNC machining, we maintain the tightest tolerances and cleanest manufacturing conditions available:

- Tolerances and Surface Finishes:

- Dimensional accuracy: ±0.001mm

- Surface finishes: Ra 0.05μm to Ra 0.4μm depending on sealing or sterilization requirements

- Flatness, roundness, and concentricity: Inspected with sub-micron-level equipment

- Equipment Overview:

- Mikron 5-axis Machining Centers: For micro-featured parts, undercuts, and complex geometries

- Mazak CNC Lathes: For turning high-precision shafts, flanges, and fittings

- Studer CNC Grinders: For ultra-precise cylindrical parts used in fluid control systems

- Zeiss CMMs and Optical Profilers: Validate tolerances and geometries required for critical assemblies

- Cleanroom Packaging Lines: For parts intended for direct cleanroom integration

- Process Highlights:

- Full traceability from raw material to final part

- ISO-compliant documentation and first article inspection (FAI)

- Deburring, ultrasonic cleaning, and clean packaging

- Batch-level lot control and labeling per customer specification

Typical CNC Machined Parts and Their Applications

We offer CNC machining for a wide variety of custom parts used in medical devices, chemical systems, and laboratory equipment, including:

- Surgical Instrument Components: Handles, blades, spacers, and locking mechanisms

- Medical Pump Rotors and Valves: For infusion pumps, diagnostic instruments, and fluid delivery systems

- Connector Bodies and Sealing Interfaces: For sterile transfer assemblies and reagent systems

- Analytical Instrument Frames and Fixtures: High-precision aluminum and stainless housings

- Sensor Mounts and Probe Housings: For spectrometry, chromatography, and thermal analysis tools

- Custom Manifolds and Flow Blocks: Micro-drilled channels for precise reagent flow in lab automation systems

- Dental & Endoscopic Assemblies: Machined with tight tolerances and ultra-smooth surfaces

Each part is manufactured according to customer drawings or 3D models, with the option to prototype, iterate, and scale to full production as needed.

Project Highlight

We recently delivered a batch of PEEK-based fluidic connectors for an automated blood analyzer system. The project required ±0.002mm tolerances, internal micro-channels, and surface roughness under Ra 0.2μm for sterile performance. All parts underwent ultrasonic cleaning, vacuum packaging, and were certified with full COC (Certificate of Conformance) and material traceability, ensuring compliance for clinical deployment.

Precision That Supports Health, Science, and Innovation

Whether you’re designing next-generation diagnostic platforms, developing lab automation systems, or fabricating life-saving surgical tools, our custom medical, chemical, and laboratory parts CNC machining services help you bring your vision to life with confidence, precision, and speed.

Contact us today to request a quote, submit your drawings, or discuss materials and machining solutions with our engineering team. From concept to cleanroom, we’re your precision partner.