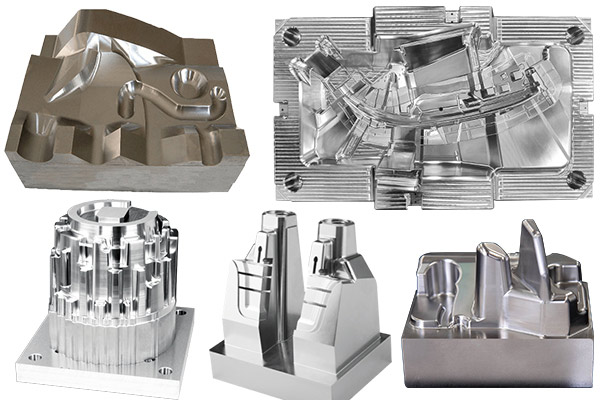

Custom Mold Components + CNC Machining — High-Precision Tooling for Injection, Die Casting, and Stamping Industries

Introduction: Precision Mold Components that Define Product Quality

In the fields of injection molding, die casting, and precision stamping, the accuracy and durability of mold components directly impact the quality, efficiency, and repeatability of the final products. From automotive interior trims to consumer electronics, and from medical devices to industrial enclosures, custom mold components play a critical role in achieving high-volume, high-precision manufacturing goals.

Our custom mold components + CNC Machining services are designed to support mold manufacturers, toolmakers, and OEMs with complex geometries, fine tolerances, and a deep understanding of tool steel and alloy behavior under pressure and heat. We help accelerate your time to market while ensuring consistent performance throughout the mold’s lifecycle.

Machining Challenges and Our Solutions

Producing mold components involves a set of engineering and machining challenges that demand experience, technology, and quality control:

- Tight Tolerances for Fit and Function: Cavity inserts, sliders, lifters, and core pins require tolerances within ±0.002mm to ensure perfect mating, proper sealing, and controlled part ejection.

- Material Hardness and Machinability: Most mold components are made from hardened tool steels (up to 60 HRC), which require advanced machining strategies, carbide tooling, and precise heat treatment.

- Complex Geometries: Ejector blades, gate inserts, and cooling channels often involve undercuts and fine features, which call for 5-axis CNC machining or EDM (Electrical Discharge Machining).

- Surface Finish for Part Release: A smooth and polished cavity surface (Ra 0.1–0.4μm) ensures clean demolding without damage to the final product.

Our Solution:

We use a combination of high-speed 5-axis machining centers, wire and sinker EDM, and precision grinding to create mold components with micrometer-level accuracy and superior surface finish. Our in-house heat treatment and polishing capabilities enable complete process control from raw material to ready-to-install components.

Common Materials and Their Characteristics

We work with a variety of high-performance materials engineered for mold applications, each selected for its mechanical strength, thermal conductivity, and wear resistance:

- Tool Steels (H13, S136, 1.2344, 1.2083): Offer excellent wear resistance, heat resistance, and polishability—ideal for high-volume plastic injection molds.

- Stainless Steels (420, 440C, 630): Provide corrosion resistance, making them suitable for molds exposed to moist or chemically reactive materials.

- Beryllium Copper (C17200): Exceptional thermal conductivity and good machinability; commonly used in core and insert applications for faster cooling.

- Aluminum Alloys (7075, 2024): Used for prototype or low-volume molds due to fast machinability and lightweight properties.

- Carbide: Employed in wear-intensive applications such as core pins or inserts in high-speed molding or abrasive plastic materials.

We provide full traceability of material certificates and can meet international standards such as ASTM, DIN, and GB.

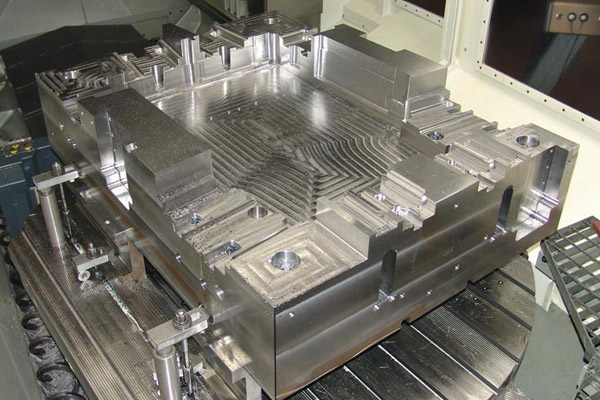

CNC Machining Capabilities

Our workshop is fully equipped to meet the precision and complexity requirements of modern mold manufacturing:

- Machining Precision:

- Dimensional tolerances: ±0.002mm

- Surface roughness: down to Ra 0.1μm for mirror-polished mold cavities

- Concentricity, perpendicularity, and true position checked via CMM

- Key Equipment:

- 5-Axis CNC Machining Centers: Capable of high-speed milling on hardened steel and beryllium copper

- Wire EDM & Sinker EDM: For sharp corners, fine features, and internal contours

- CNC Grinding Machines: For achieving ultra-precise flatness and finishes on plates and inserts

- CMMs and 3D Optical Scanners: For full dimensional inspection and reverse engineering

- In-house Heat Treatment: Including quenching, tempering, and stress relief for consistent hardness profiles

- Value-Added Services:

- Mirror polishing

- Nitriding and PVD coatings

- Assembly and fitting of mold bases, guide pillars, and locating rings

Common Mold Components and Applications

We manufacture a wide range of custom mold components that are essential in plastic injection molds, die casting tools, and progressive stamping dies:

- Cavity and Core Inserts: Machined to exact geometries for accurate product molding

- Ejector Pins and Sleeves: Precision-ground for consistent part ejection

- Lifters, Slides, and Cam Blocks: Complex moving components for undercut and side-action release

- Cooling Inserts and Baffles: Designed with internal channels for efficient thermal control

- Sprue Bushings and Gate Inserts: Hardened for long life and polished for smooth melt flow

- Die Plates and Spacers: Milled and ground flat to ensure proper mold assembly and clamping

Whether you are producing automotive panels, consumer electronics, home appliance parts, or medical disposables, our precision mold components ensure performance under pressure.

Project Example

We recently delivered a full set of custom mold inserts and ejector pins for a multi-cavity mold used in high-volume production of automotive sensor housings. The project required ±0.002mm tolerances, S136 stainless steel for corrosion resistance, and a mirror-polished surface of Ra 0.2μm. After machining and polishing, all components were verified using Zeiss CMM equipment and shipped with full dimensional and material certification. The customer reported a 40% increase in tooling lifespan compared to their previous supplier.

Trust a Proven CNC Machining Partner for Custom Mold Components

As a custom mold components + CNC Machining specialist, we are committed to helping you build better tools with shorter lead times, tighter tolerances, and longer service life. Whether you’re producing prototypes or scaling to high-volume production, we deliver the precision your molds demand.

Contact us today to discuss your mold component requirements. Upload your 2D drawings or 3D CAD files, and let our engineering team assist with DFM analysis, material selection, and cost-effective machining solutions.

Keywords naturally embedded: custom mold components, CNC Machining, precision ejector pins, 5-axis machining for mold parts, S136 stainless steel inserts, ±0.002mm tolerance, EDM mold component machining, Ra 0.2μm surface polishing, injection mold tooling, hardened tool steel CNC.