Precision CNC Machining of Ruby and Sapphire Components for Global Markets

In the rapidly evolving global marketplace, the demand for ultra-precise components made from high-performance materials continues to grow. Among these, ruby and sapphire components stand out for their exceptional hardness, durability, and optical qualities, making them essential in cutting-edge industries such as aerospace, medical devices, and high-tech automation. To meet these demanding requirements, specialized CNC machining services have become vital, offering tailored solutions that combine advanced technology with extensive experience. This article explores the capabilities and advantages of high-precision CNC machining of ruby and sapphire components for international markets, highlighting the key factors that ensure quality, consistency, and innovation.

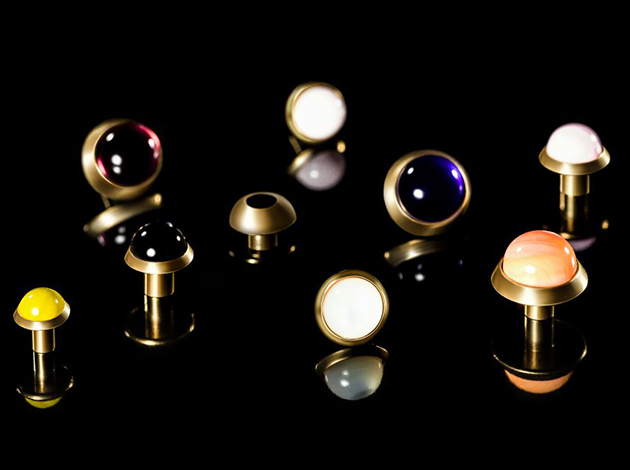

Ruby component & Sapphire component

High-Precision Ruby and Sapphire Components for Global Markets

Manufacturing ruby and sapphire components at a high precision level is crucial for their optimal performance in demanding applications. These materials, known for their hardness and optical clarity, are used in everything from laser systems to high-precision sensors. Globally, industries rely on manufacturers capable of producing tiny, complex parts with strict tolerances, often up to ±0.001mm. Advanced CNC machining provides the necessary control and accuracy, ensuring components meet rigorous specifications. By leveraging state-of-the-art equipment and skilled expertise, manufacturers can deliver these high-quality parts consistently across international markets. The ability to produce complex geometries, such as intricate channels or optical features, makes CNC machining the preferred choice for ruby and sapphire components worldwide.

Ruby component & Sapphire component

Custom CNC Machining Based on Client Drawings and Specifications

Customization is the cornerstone of modern manufacturing for high-performance materials like ruby and sapphire. Clients often provide detailed drawings and specifications, requiring manufacturers to translate these designs into precise physical parts. Custom CNC machining offers the flexibility necessary to accommodate complex shapes, tight tolerances, and specialized finishing requirements. Manufacturers work closely with clients to understand project demands and develop tailored solutions, whether it involves micro-drilling, polishing, or intricate surface treatments. This collaborative approach ensures that each component aligns perfectly with the intended application, enhancing functionality and performance. The ability to adapt to unique and complex designs positions CNC machining as an ideal partner for clients across sectors such as aerospace, medical, and consumer electronics.

Ruby component & Sapphire component

Versatile Material Capabilities for Complex and Hard Materials

Beyond ruby and sapphire, modern CNC machining can handle a wide array of materials, including stainless steel, aluminum alloys, titanium, copper, and engineering plastics like PEEK and ceramics. This versatility allows manufacturers to serve diverse industries with varying material requirements, from lightweight aerospace parts to biocompatible medical implants. The experience in machining hard-to-cut materials ensures high precision and surface finish quality, even with extremely tough substrates. Such capability is essential when working with sapphire and ruby, which require specialized tools and techniques due to their hardness and brittleness. An extensive understanding of different materials and their machining behaviors enables manufacturers to deliver complex components that meet the highest standards of quality and durability.

Ruby component & Sapphire component

Achieving Tolerance Levels Up to ±0.001mm for Critical Components

Achieving extremely tight tolerances is vital in industries where precision directly impacts performance and safety. CNC machining facilities equipped with advanced technology can consistently produce components with tolerances as precise as ±0.001mm. For ruby and sapphire parts used in laser optics, sensors, or aerospace instrumentation, such precision ensures perfect fit and optimal functionality. This level of accuracy demands meticulous process control, high-quality tooling, and rigorous inspection procedures. Manufacturers employ coordinate measuring machines (CMM) and other inspection tools to verify each component’s dimensions, ensuring they meet exact specifications. The commitment to precision enhances reliability and performance in high-stakes applications worldwide.

Ruby component & Sapphire component

Advanced Manufacturing Equipment for Superior Precision and Quality

The backbone of high-precision CNC machining lies in sophisticated equipment that offers exceptional control and flexibility. Five-axis CNC machining centers enable complex geometries to be produced with minimal tooling changes, reducing lead times and increasing accuracy. Mill-turn machines combine milling and turning operations for complex, multi-faceted parts. Wire EDM (Electrical Discharge Machining) allows precise cutting of intricate features in hard materials like sapphire and ruby without inducing cracks or damage. Additionally, coordinate measuring machines (CMM) facilitate comprehensive inspection and quality assurance. These advanced tools, coupled with skilled operators, ensure each component meets the strictest standards of quality, surface finish, and dimensional accuracy.

Ruby component & Sapphire component

Nearly 20 Years of Expertise Serving International Aerospace, Medical, and Industrial Clients

With nearly two decades of dedicated experience, CNC machining manufacturers have built a reputation for delivering high-quality, reliable components to global clients. Their expertise spans multiple high-end industries, including aerospace, medical devices, energy, and automation. This extensive background enables them to understand complex project requirements and provide innovative solutions tailored to each client’s needs. Their proven track record of working with international standards and delivering consistent quality underpins their reputation as trusted partners worldwide. The experience gained from serving high-profile projects ensures that clients receive not only precision parts but also comprehensive support throughout the manufacturing process.

Ruby component & Sapphire component

Serving Clients from Europe and the U.S. with Consistent Quality and Reliable Lead Times

Manufacturers committed to excellence prioritize customer satisfaction by offering stable quality and dependable delivery schedules. For clients across Europe and North America, this means adhering to international standards and providing transparent communication throughout the project lifecycle. The ability to deliver custom ruby and sapphire components promptly, without compromising on quality, builds long-term relationships and trust. Advanced scheduling, streamlined logistics, and quality control systems ensure that clients receive their parts on time and to specifications. Such reliability makes these CNC machining providers ideal partners for high-stakes projects requiring precision, consistency, and excellence.

In a global market where precision, quality, and customization are paramount, advanced CNC machining of ruby and sapphire components stands out as a vital capability. Combining cutting-edge technology with nearly 20 years of industry expertise, manufacturers now deliver high-precision, complex parts tailored to the exact needs of aerospace, medical, and industrial sectors worldwide. Their versatility in material processing, stringent tolerance controls, and commitment to quality make them trusted partners for international clients seeking reliable, high-performance solutions. As industries continue to push the boundaries of technology, CNC machining of ruby and sapphire components will remain at the forefront of innovation and excellence.