Precision Custom Shaft and Sleeve Machining for High-End Industries

In the realm of high-end industries, precision and reliability are paramount. Custom shafts and sleeves, especially those featuring complex splines, serve as critical components in aerospace, medical devices, energy systems, and automation machinery. Achieving the highest standards in these parts demands advanced manufacturing techniques, sophisticated materials, and meticulous quality control. This article explores how state-of-the-art CNC machining capabilities are enabling manufacturers to produce highly precise, durable, and complex custom shafts and sleeves, tailored perfectly to client specifications, with exceptional accuracy and consistency.

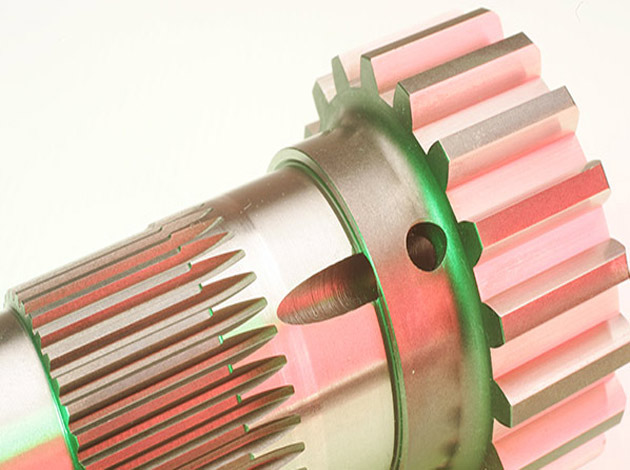

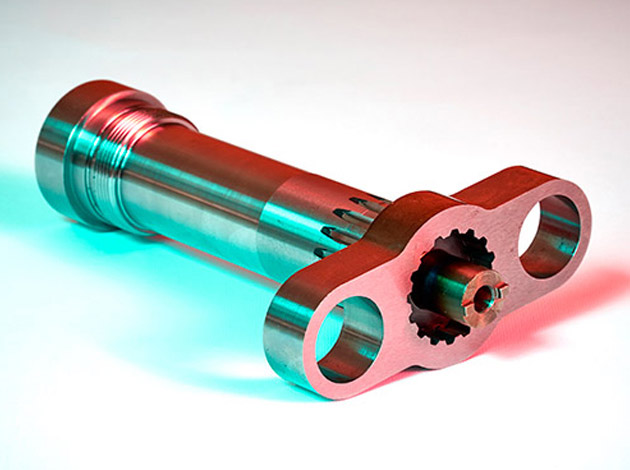

Spline shaft and spline sleeve

Advanced CNC Machining for High-Precision Shafts and Sleeves

High-end industries rely heavily on components that are manufactured with extraordinary precision. Advanced CNC machining techniques—including 5-axis milling, multi-axis turning, and wire EDM—are essential to meet these demanding standards. Such machinery allows for complex geometries, tight tolerances, and intricate features to be machined in a single setup, reducing errors and enhancing consistency. The ability to produce sophisticated spline profiles, internal bores, and surface finishes ensures that each shaft and sleeve performs flawlessly under operational stresses. Precision machining also minimizes material waste, making the process more sustainable and cost-effective. Moreover, automated tool changers and real-time monitoring contribute to higher efficiency and faster turnaround times, critical for high-volume projects. The integration of advanced CNC technology ensures that every component adheres to the strictest quality standards, supporting the reliability required in high-end applications.

Spline shaft and spline sleeve

Custom Design Capabilities Based on Customer Drawings

Every high-precision shaft and sleeve begins with detailed customer drawings and specifications. Our manufacturing process is fully adaptable to custom designs, ensuring that each component precisely matches the client’s requirements. From simple straight splines to complex helical profiles, our team works closely with clients to interpret their drawings and translate them into manufacturable parts. We utilize CAD/CAM software to simulate and optimize machining strategies before production begins, preventing potential issues. This collaborative approach ensures that each part’s dimensions, surface finishes, and tolerances are meticulously controlled. Our engineers also offer consultation to refine designs for manufacturability, which can reduce costs and improve performance. No matter how complex or unique the design, our dedicated team is committed to turning client visions into high-quality, ready-to-use components. This bespoke approach guarantees that our clients receive parts that meet their precise engineering needs.

Spline shaft and spline sleeve

Wide Range of Materials Including Metals, Plastics, and Ceramics

One of our core strengths is our extensive experience working with a variety of materials suitable for high-end industries. We can process metals such as stainless steel, aluminum alloys, titanium, and brass—materials known for strength, corrosion resistance, and lightweight properties. Harder materials like hardened alloys and ceramics are also within our machining capabilities, allowing us to produce components for extreme environments. In addition, we work with engineering plastics like PEEK, which offer excellent chemical resistance and biocompatibility, ideal for medical and aerospace applications. Ceramics and 3D-printing materials are also part of our portfolio, enabling the creation of complex, high-performance parts. Our team understands the unique challenges posed by each material, from tool selection to cooling strategies, ensuring that every component maintains its integrity and surface quality. This broad material proficiency allows us to meet diverse project requirements across multiple high-end sectors.

Spline shaft and spline sleeve

Achieving Tolerance Levels as Tight as ±0.001mm

In high-precision industries, even the slightest deviation can compromise performance or safety. Our machining facilities are equipped to achieve tolerance levels as tight as ±0.001mm, ensuring that each part fits perfectly within its assembly. This capability is especially critical for splined shafts and sleeves, where dimensional accuracy directly affects torque transmission, rotational stability, and longevity. To attain such precise tolerances, we employ high-precision measurement tools like Coordinate Measuring Machines (CMM) for real-time inspection during and after machining. Our team meticulously monitors dimensional parameters at every stage, adjusting machining parameters as needed to maintain tight control. This rigorous quality assurance process guarantees that all components meet or exceed industry standards, particularly in aerospace, medical, and military applications. Achieving such high accuracy consistently sets us apart as a trusted supplier of high-end, precision-crafted parts.

Spline shaft and spline sleeve

State-of-the-Art Equipment Ensuring Superior Quality

Our commitment to quality is backed by a comprehensive suite of advanced manufacturing equipment. We utilize five-axis CNC machining centers capable of complex multi-surface machining in a single setup. Mill-turn machines combine turning and milling processes, reducing the need for multiple setups and improving precision. Wire EDM (Electrical Discharge Machining) allows us to produce intricate shapes and fine details in hard materials with minimal thermal distortion. For inspection, we employ CMM systems with high-resolution probes to verify dimensions down to the micron level. Additionally, our equipment features automatic tool changers, high-speed spindles, and adaptive control systems that optimize machining parameters for each task. These technological investments ensure that every component is manufactured with the highest accuracy, surface finish, and consistency. Continuous upgrades and stringent maintenance protocols keep our equipment at the forefront of manufacturing technology, supporting our reputation for superior quality.

Spline shaft and spline sleeve

Trusted Partner for Global High-End Industry Projects

With nearly two decades of experience in precision machining, we have built a reputation as a reliable partner for high-end industry projects worldwide. Our portfolio includes collaborations with aerospace giants, medical device manufacturers, energy companies, and automation firms. We understand the importance of confidentiality, strict quality standards, and timely delivery in these sectors. Our ability to provide customized, high-precision shafts and sleeves has earned us long-term relationships with clients across Europe, North America, and Asia. We are committed to continuous improvement, investing in the latest technology and training to ensure our manufacturing processes stay ahead of industry demands. Our dedicated customer service team works closely with clients from initial design to final inspection, offering comprehensive solutions that meet their exact specifications. As a trusted supplier, we are proud to contribute to high-end projects that require the utmost precision, reliability, and innovation.

In conclusion, our advanced CNC machining capabilities enable us to produce highly precise, complex shafts and sleeves tailored to the stringent requirements of high-end industries. From custom design and material versatility to tight tolerances and superior equipment, we are committed to delivering top-quality components that meet and exceed client expectations. With our extensive experience and global reach, we stand as a reliable partner for innovative projects demanding the highest standards in precision engineering.