Precision Manufacturing for Construction Machinery & Industrial Automation: Why Global Brands Choose China

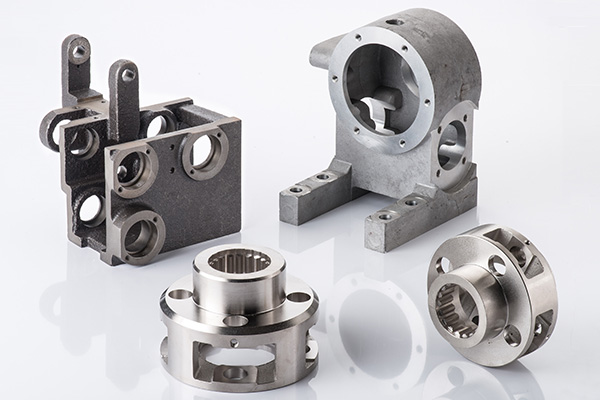

As global industries push toward smarter, more durable, and higher-efficiency systems, the precision requirements of components used in construction machinery and industrial automation have reached unprecedented levels. China’s high-precision component manufacturers, backed by nearly 20 years of deep machining expertise, have become trusted partners for global OEMs and system integrators seeking both performance and reliability.

From early design consultation to drawing-based customization, from materials management to process optimization, Chinese manufacturers are delivering much more than parts—they are delivering complete manufacturing solutions tailored for high-load, high-frequency, and high-precision applications.

1. Early-Stage Technical Collaboration with Design Engineers

In heavy-duty construction systems and automated production lines, even small deviations in part geometry can lead to costly system inefficiencies or failures. That’s why top-tier Chinese manufacturers prioritize engineering collaboration from day one.

Our technical team works closely with your design engineers to:

- Review 2D/3D drawings for manufacturability

- Suggest design adjustments to improve component life

- Provide feedback on materials and tolerance capabilities

- Assist in fast prototyping and iteration

This design-for-manufacturing (DFM) support significantly reduces your development cycle and ensures that critical parts—like hydraulic valve spools, bearing housings, gear shafts, sensor brackets, and actuator components—are functionally optimized for real-world demands.

2. Custom Machining Based on Drawings and Specs

Whether it’s high-load structural parts for excavators or precision-fitted motion components for robotic systems, we offer full-spectrum custom CNC machining based on your technical drawings. Our capabilities cover:

- Multi-axis turning and milling (3, 4, 5-axis)

- Precision grinding, honing, and EDM

- Assembly fit part matching and performance testing

- Tolerance control up to ±0.001mm

- Surface finish Ra0.2μm or better

Each component is crafted to your exact specifications, backed by ISO-certified quality management and full process documentation.

3. Materials Management with Full Traceability

Heavy industry components demand materials that can withstand high mechanical stress, thermal cycling, and environmental exposure. We leverage a mature and diversified materials supply chain, enabling us to source, process, and certify a wide range of metals and composites, including:

- Alloy steels (42CrMo, 20CrMnTi)

- Hardened tool steels (SKD11, D2)

- Stainless steel (304/316)

- Aluminum alloys (6061, 7075)

- Engineering plastics (PEEK, PA6, PTFE)

Our team ensures batch-level material traceability, pre-treatment (annealing, quenching, nitriding), and post-machining surface treatments like black oxide, anodizing, and zinc plating—delivering components that perform reliably under demanding field conditions.

4. Process Optimization for Cost and Performance

With nearly 20 years of hands-on experience in complex part machining, we understand how to balance precision, cost-efficiency, and performance. By refining the tooling path, machine parameters, and inspection methods, we help our clients achieve:

- Lower defect rates in automated assemblies

- Longer service life in mobile machinery

- Consistent interchangeability in batch production

Our modern workshops feature high-end equipment from MAZAK, DMG Mori, STÜDERT, and Mitutoyo, along with CMMs, roundness testers, and roughness meters for 100% quality assurance.

5. Reliable Delivery and Global Fulfillment Support

For industrial clients, timing is everything. Delayed components can halt a production line or ground a piece of equipment. That’s why we’ve built a responsive production and logistics system with:

- Flexible capacity to meet urgent production spikes

- Transparent scheduling and weekly progress updates

- Export packaging and international shipping coordination

- On-time delivery rates above 98%

Whether you need one-off prototypes, small-batch validation, or high-volume production, we’re equipped to scale efficiently while maintaining precision and consistency.

Partnering for the Future of Machinery and Automation

From robotic arms to construction-grade hydraulics, our precision parts are already powering automation and machinery systems across Europe, North America, and Southeast Asia. As global industries pursue smart manufacturing and durable automation, China’s precision machining capabilities offer a unique advantage—cost-effective excellence with engineering depth.

Let’s co-engineer high-performance solutions.

Contact our team today to explore how we can bring precision to your machinery and automation systems.