Precision CNC Machining for the Optics Industry: China’s Rising Advantage in Global High-Precision Manufacturing

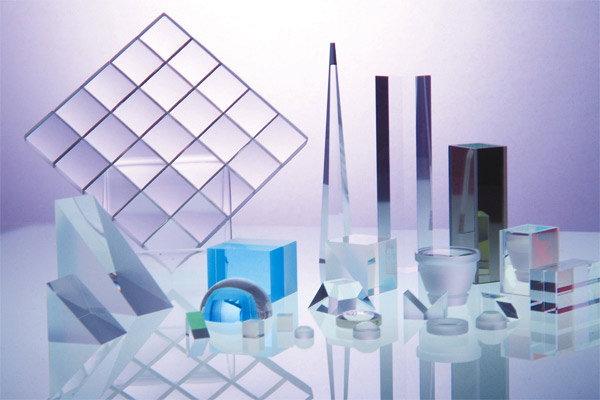

In the optics industry, where tolerances are measured in microns and surface finishes directly impact optical performance, the demand for ultra-precise, stable, and repeatable component manufacturing is non-negotiable. From lens holders and prism mounts to precision frames and light-shielding parts, the structural backbone of every high-performance optical system depends on the quality of its mechanical components.

Chinese high-precision machining manufacturers are increasingly becoming the preferred partners for global optics companies, offering not only competitive pricing, but also unmatched integration of design collaboration, material management, advanced processing, and precision verification.

1. Early-Stage Engineering Support for Functional Perfection

In optical assemblies, form directly affects function—even microscopic misalignments can lead to distortion, misfocus, or signal loss. Recognizing this, Chinese manufacturers now go far beyond build-to-print services.

We actively engage in deep technical communication with optical design engineers, especially in the early stages of R&D and prototyping. Our engineering support includes:

- 3D drawing validation for manufacturability

- Design adjustment for optimal alignment and stability

- Simulation of thermal deformation or material behavior

- Joint prototyping for lens assemblies, optical tubes, and alignment guides

Through this collaborative approach, we help customers avoid downstream errors and achieve faster, first-time-right production of critical components.

2. Drawing-Based Custom Machining with Sub-Micron Tolerances

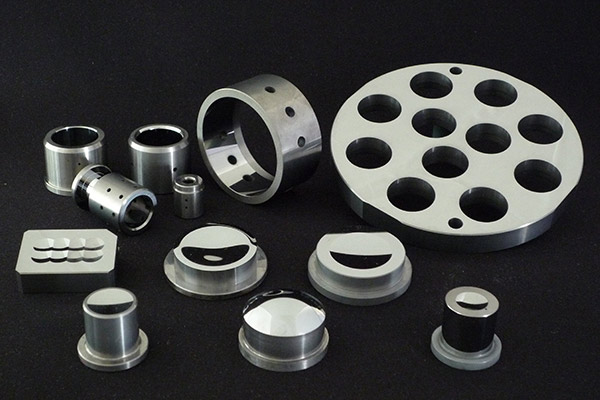

Our factories specialize in custom CNC machining based on client drawings, with tight control over dimensional accuracy, concentricity, and surface flatness—key performance factors in optical assemblies.

We routinely produce parts such as:

- Optical lens holders and barrels

- Beam-splitting housings

- Collimator brackets

- Optical alignment fixtures

- Thin-wall aluminum and titanium structures

Tolerances can be controlled within ±0.001mm, and surface finishes reach Ra0.1–0.2μm, meeting the most demanding requirements in imaging, laser optics, and analytical instrumentation.

3. Advanced Materials with Full Process Traceability

Optical systems often require lightweight, stable, and thermally inert materials to ensure imaging quality and alignment precision under variable conditions. Our team has long-term experience machining and post-processing:

- Aluminum 6061-T6, 7075

- Titanium alloy (Ti6Al4V)

- Optical-grade stainless steel (SUS303/316)

- Copper, Invar, and Kovar

- Engineering plastics: PEEK, Delrin, PTFE

- Optical ceramics and sapphire (upon request)

We provide material certification, batch traceability, and assist in selecting the most suitable material based on thermal stability, machining behavior, and environmental exposure.

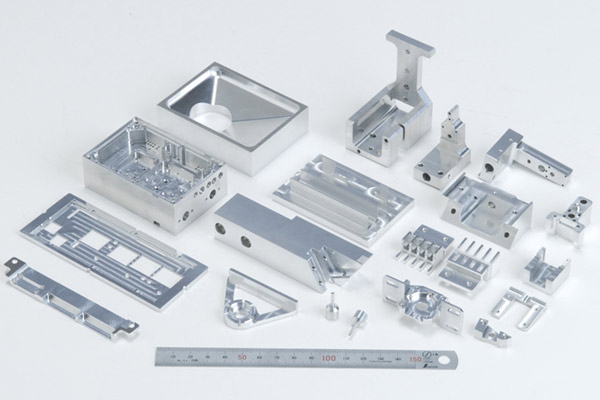

4. Nearly 20 Years of Craftsmanship and Process Optimization

Our team has accumulated nearly two decades of precision machining experience, with extensive knowledge in machining thin-wall structures, complex geometries, and mirror-quality surfaces.

Each part goes through a carefully optimized process chain:

- CAM programming with simulation

- High-speed CNC milling and turning

- Precision grinding and lapping

- Surface passivation, anodizing, or black coating (non-reflective)

- Full-dimensional inspection with Zeiss CMM, form testers, and optical comparators

This ensures that every optical component we deliver meets stringent tolerances for shape, smoothness, and alignment compatibility.

5. On-Time Delivery and Global Trust

Time-sensitive optical projects—especially for aerospace, medical imaging, and scientific instrumentation—require predictable and reliable delivery. With integrated scheduling systems, flexible production lines, and international shipping support, we maintain:

- 95%+ on-time delivery rate

- Weekly production updates

- Export-ready packaging and documentation

- Engineering change agility and quick re-runs for iteration

We understand that optical components are often part of mission-critical systems. That’s why we build trust not just through parts—but through reliability.

Partner with China’s Precision Optics Manufacturing Experts

From lens alignment bases to ultra-precise structural components, Chinese precision manufacturers are now globally recognized not just for affordability, but for their engineering depth, material expertise, and ability to deliver results at scale.

If you’re looking for a machining partner who can co-develop high-precision optical components with you—from concept through to mass production—we’re ready to deliver with precision, agility, and insight.

Let’s make optical precision visible, together.