Precision CNC Machining for the Aerospace Industry: How China Delivers Mission-Critical Quality at Global Standards

In aerospace manufacturing, every micron matters. From turbine housings to structural brackets, flight-critical components must meet the highest standards of precision, consistency, and reliability. Today, China’s high-end CNC machining manufacturers are emerging as trusted global partners in aerospace precision engineering—offering not just cost-efficiency, but also deep technical collaboration, advanced materials handling, and proven quality systems.

With nearly two decades of experience, China’s precision suppliers are not only catching up—they are delivering on the world’s most demanding aerospace requirements.

1. Early-Stage Technical Integration with Aerospace Engineers

Aerospace components are often designed with ultra-tight tolerances, complex geometries, and unique material requirements. The ability to communicate deeply with design engineers during early development is essential.

At our facility, we don’t simply “follow the drawing”—we become engineering partners in every project. Our support includes:

- Reviewing 3D models and GD&T standards

- Advising on process feasibility and material selection

- Simulating thermal deformation, stress behavior, and machining response

- Providing rapid prototyping with feedback loops for design improvement

This front-loaded technical collaboration ensures that every aerospace part—from engine mounts to inertial system brackets—is manufacturable, functional, and optimized before full-scale production begins.

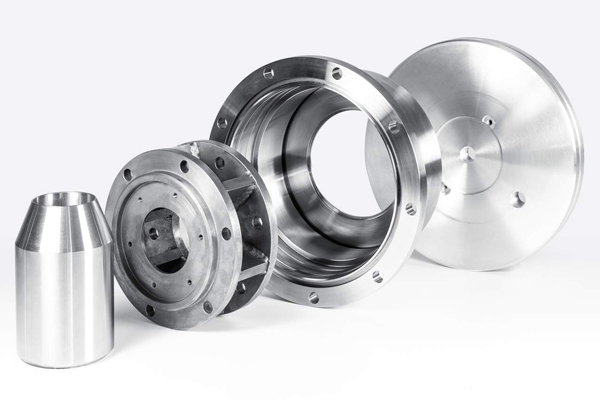

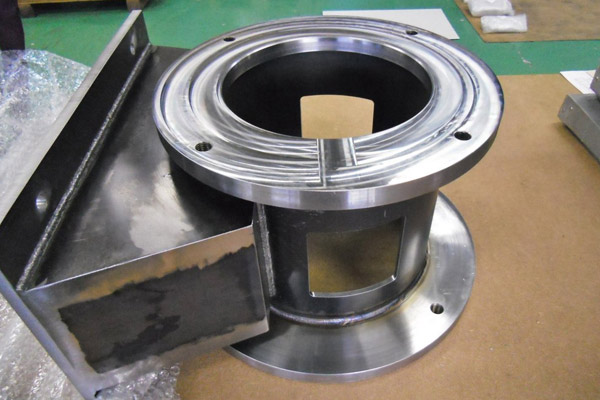

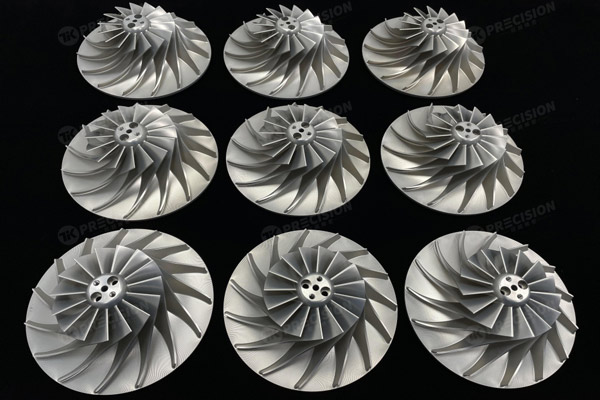

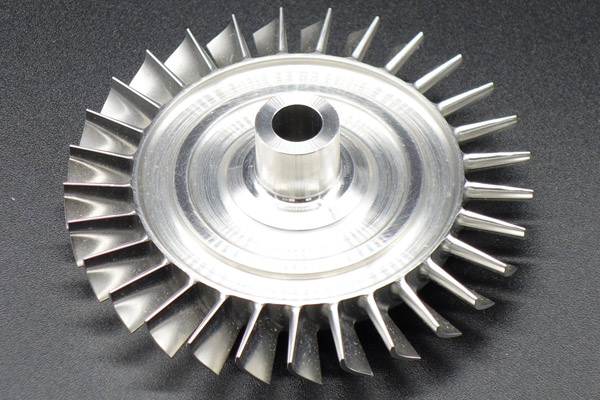

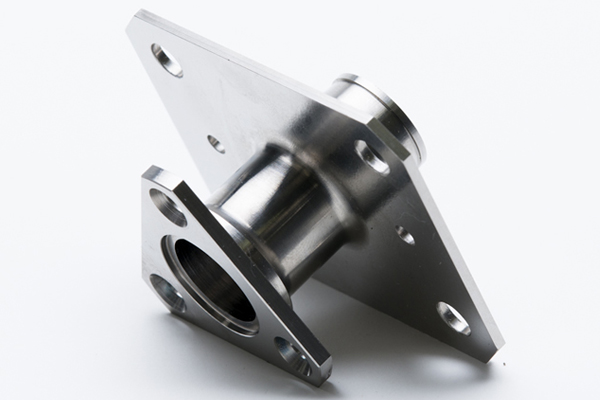

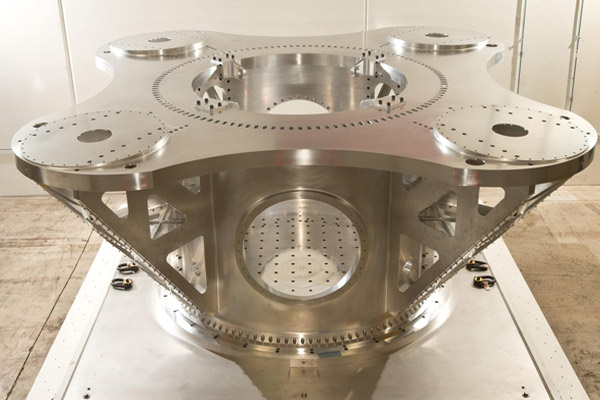

2. Custom CNC Machining Based on Drawings and Aerospace Standards

We specialize in custom machining of aerospace-grade parts based on client drawings and specifications, with a strict focus on tolerance control, consistency, and quality traceability.

Our capabilities include:

- 5-axis precision milling and turning

- EDM, grinding, and honing for critical tolerance zones

- CNC machining of complex lightweight structures

- Tolerance control down to ±0.001mm

- Surface finish up to Ra0.2μm

Common components we deliver for aerospace applications:

- Engine turbine casings and shaft housings

- Landing gear bushings, actuators, and linkages

- Avionics enclosures and thermal mounts

- Satellite structural parts and sensor brackets

- Jet nozzle components and cavity parts

3. Aerospace Materials Expertise with Full Chain-of-Custody Control

Aerospace-grade parts demand certified, traceable, and expertly processed materials. We work with a broad range of high-performance materials including:

- Titanium alloys (Ti-6Al-4V / Grade 5)

- Aluminum alloys (7075, 2024, 6061)

- Stainless steel (17-4PH, 316L, 304)

- Inconel, Hastelloy, and other superalloys

- Aviation-grade engineering plastics (PEEK, PPSU)

- Carbon fiber composite-compatible metallic interfaces

Every material batch is subject to certified sourcing, traceability protocols, and custom heat treatments, ensuring compliance with aerospace norms such as AS9100, AMS, and MIL standards (where applicable).

4. Process Optimization and Quality Assurance at Aerospace Precision

With nearly 20 years of high-precision machining experience, we apply aerospace-level rigor across all manufacturing stages. From CAM simulation to toolpath optimization, each part is produced under a closed-loop quality system.

Key features include:

- Zeiss 3D CMM inspection with full digital reports

- Roundness and concentricity testing (<0.002mm)

- Non-destructive testing (upon request)

- Surface treatment control (anodizing, passivation, conversion coating)

- ISO9001 & ISO13485-certified workflows; AS9100-ready procedures

We also provide PPAP, FAI (First Article Inspection), and full documentation for aerospace audits and supply chain integration.

5. On-Time Delivery for Mission-Critical Projects

In aerospace programs, timing is as critical as precision. From initial prototype to batch production and part revisions, our team ensures seamless project management and flexible capacity.

We offer:

- Rapid lead times from prototyping to production

- Dedicated project engineers for timeline control

- Global shipping logistics and export compliance

- Weekly updates and online progress tracking

- 98%+ on-time delivery rate, even under tight deadlines

China’s Precision Manufacturers Are Ready for Aerospace Challenges

Global aerospace OEMs and Tier 1 suppliers are increasingly recognizing the value of Chinese machining partners who offer not only lower costs, but world-class engineering support, material control, process excellence, and responsive delivery.

From unmanned aerial vehicles (UAVs) to commercial aircraft and satellite components, we deliver precision, reliability, and partnership—at every stage of flight.

Let’s engineer aerospace excellence together.