Precision Machining for Medical, Chemical & Laboratory Equipment: Why China Is a Trusted Global Manufacturing Partner

In highly regulated, precision-driven sectors such as medical devices, chemical processing, and laboratory instrumentation, there’s zero tolerance for deviation. Components must meet the highest standards in tolerance, cleanliness, biocompatibility, and documentation—often with custom features, low batch volumes, and tight development cycles.

As a Chinese precision machining manufacturer with nearly 20 years of experience, we have consistently delivered critical components to medical equipment OEMs, analytical device manufacturers, and lab automation innovators across the globe. From early-stage engineering collaboration to drawing-based production and regulatory-aligned documentation, we serve as a value-added manufacturing partner in this mission-critical sector.

1. Early Engineering Collaboration: Supporting Innovation with Practical Manufacturing

We work closely with design engineers, R&D teams, and medical product developers to ensure every component meets its intended function while remaining cost-effective and manufacturable.

Our early involvement includes:

- Reviewing part geometry for functional fit and cleanability

- Suggesting DFM optimizations to reduce unnecessary complexity

- Advising on material selection for biocompatibility, chemical resistance, and thermal stability

- Simulating use-case scenarios for valve bodies, chambers, mounting frames, or pump interfaces

- Ensuring feasibility for small-batch prototyping and smooth transition to production

Whether it’s a surgical device prototype, a fluidic manifold for chromatography, or a sensor mount for automated analysis systems, our technical team bridges the gap between CAD and real-world precision.

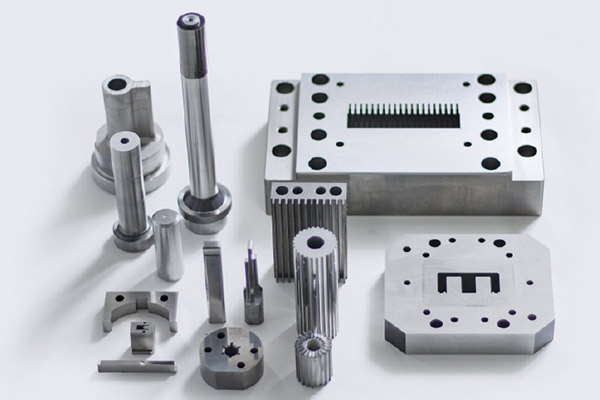

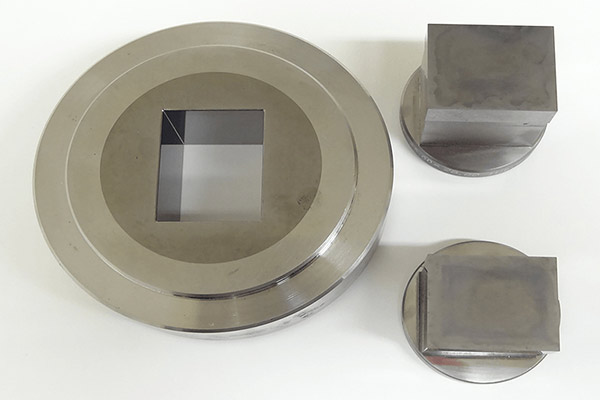

2. Custom, Drawing-Based Machining for High-Purity Applications

We specialize in drawing-based, CNC-machined parts tailored to life sciences and chemical research applications. Typical components include:

- Precision housings, connectors, and couplings for diagnostic machines

- Valve seats, fluid blocks, and manifolds for lab instruments

- Sensor holders and lens retainers for optical analysis tools

- Medical-grade mounting plates, arms, and actuator components

- Stainless fittings, adaptors, and micro-scale parts for dispensing systems

Capabilities:

- 3/4/5-axis CNC milling and multi-axis turning

- Tolerance control down to ±0.005 mm

- Surface finish as low as Ra 0.4 µm for hygienic sealing

- Cleanroom-compatible deburring and polishing

- Delicate handling of thin-wall or micro-scale components

Our parts are ready for integration into clean environments—including ISO class 7+ cleanroom systems and FDA-compliant assemblies.

3. Material & Surface Treatment Expertise for Cleanroom and Bio-Safe Applications

High-performance materials and contamination-free finishes are essential in medical and lab environments. We provide:

✅ Commonly machined materials:

- 316L / 304 stainless steel for corrosion resistance and cleaning

- Titanium (Grade 2/5) for biocompatible implants or structural parts

- PEEK, PTFE, PPSU for thermal and chemical stability in lab environments

- Aluminum 6061 / 7075 for lightweight non-contact components

- Quartz glass or ceramic fixtures (outsourced with integration machining)

✅ Surface treatments tailored to medical standards:

- Electropolishing for bio-smooth stainless parts

- Passivation (per ASTM A967) for corrosion resistance

- Anodizing for aluminum optical frames and handles

- High-purity ultrasonic cleaning

- Optional clean packaging, ISO-7 compatibility, and RoHS/FDA documentation

4. Nearly Two Decades of Precision Manufacturing for Regulated Industries

We are not just machinists—we’re problem solvers for highly technical, quality-critical fields. Key credentials include:

- Extensive experience with IATF 16949 / ISO 13485 / FDA-aligned projects

- Full material traceability and first article inspection (FAI)

- Batch-controlled production with CMM reports, RoHS/REACH certs, and more

- In-house QA lab: CMM, profile projectors, hardness testers, surface finish gauges

- Support for low-volume production, pre-series runs, and serial manufacturing

Whether you’re a global med-tech innovator or a scientific instrumentation OEM, we align with your quality management systems and regulatory needs.

5. Flexible Lead Times & Reliable Global Delivery

In this field, delivery delays can compromise R&D schedules or regulatory filings. That’s why we’ve built a supply chain optimized for reliability:

- Fast project kick-off and clear communication

- Lead times from 7–30 days, depending on complexity

- Batch traceability and serialization available

- Anti-static, cleanroom-safe packaging upon request

- International shipping coordination and customs-friendly documentation

We serve customers in Europe, North America, and Asia-Pacific, with consistent on-time delivery and engineering responsiveness throughout the process.

Why Leading Medical & Laboratory Equipment Manufacturers Choose China

China’s high-end precision manufacturing sector offers a rare combination of technical competence, scalability, and cost-efficiency, backed by a strong culture of process control and engineering collaboration.

Here’s why global innovators trust Chinese machining suppliers like us:

✔ Deep understanding of medical and lab equipment functionality

✔ Ability to handle small-batch, high-mix, or development-stage components

✔ Experience with biocompatible materials and ultra-clean machining standards

✔ Short lead times and seamless communication in English

✔ Full documentation support for regulated markets

Partner with us to develop the next generation of medical, chemical, and lab precision components—delivered with accuracy, care, and global confidence.