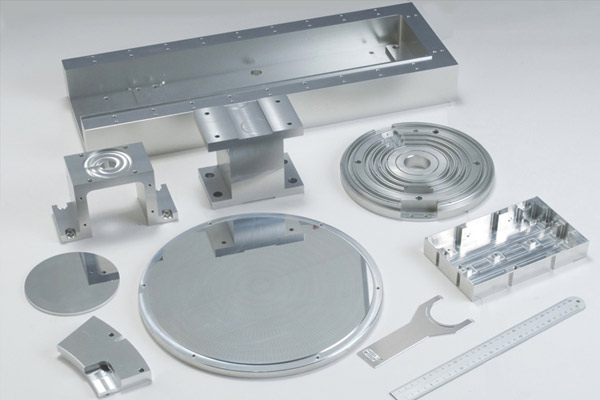

High-Precision Machining for Etching & Deposition Equipment Components

Your Trusted CNC Partner for CVD, PVD, ALD, and Plasma Etching Applications

Etching and deposition are the heart of semiconductor device fabrication, involving extreme environments — from high-temperature plasma to ultra-pure vacuum gas systems. The components used in these chambers must not only resist chemical and thermal attacks but also maintain geometric precision under prolonged stress cycles.

With over 20 years of CNC machining experience, our Chinese facility has supported global semiconductor leaders by producing chamber liners, gas rings, shower heads, electrode holders, and more — all with uncompromising precision and surface control.

✔ Key Machining Challenges in Etching & Deposition Parts

Etch and deposition parts face a unique combination of machining and performance challenges:

- High-temperature & corrosive environments: Parts must endure >600°C, aggressive gases (CF₄, Cl₂, O₂), and vacuum plasma bombardment.

- Complex internal geometries: Gas distribution rings and shower heads often require hundreds of ultra-fine, evenly distributed microholes.

- Dimensional stability: Thermal expansion, warping, or chemical degradation are unacceptable — tight tolerances must hold during operation.

- Low contamination requirement: Any burrs, residues, or surface defects may lead to process defects or wafer contamination.

✔ Materials & How We Handle Them for Peak Performance

We select and precisely machine materials that offer high thermal and chemical stability:

| Material | Application | Optimization Methods |

|---|---|---|

| High-Purity Aluminum (6061-T6 / 7075) | Gas rings, chamber bodies | CNC + Anodizing (Type II/III) for corrosion and dielectric protection |

| Titanium & Titanium Alloys | Plasma-facing components | High-speed turning + argon-protected welding |

| Quartz & Fused Silica | Shower heads, liners | Laser micro-drilling + optical-grade polishing |

| Alumina / AlN / SiC Ceramics | Electrode holders, liners | Diamond grinding + mirror polishing (Ra < 0.1μm) |

| Stainless Steel (SUS316L) | High-purity gas manifolds | CNC + Electro-polishing for internal smoothness |

All materials are sourced from certified global suppliers, including CoorsTek, Momentive, and Mitsubishi Materials.

✔ Advanced CNC Capabilities & Inspection for These Components

To meet the stringent demands of etch and CVD/ALD toolmakers, our factory integrates:

- 5-Axis Simultaneous CNC Centers – For machining internal cavities, inclined micro-channels, and multi-surface hole arrays

- Diamond & CBN Grinding Systems – For ceramic flatness, roundness, and micro-chamfering

- High-Precision EDM & Laser Drilling – Achieving hole diameters down to 0.15mm with even spacing

- Automated Polishing & Lapping Units – For achieving plasma-compatible surfaces

- Vacuum Brazing & Helium Leak Testing – For sealed assemblies like gas showers and liners

Every part undergoes:

- CMM dimensional verification – Zeiss PRISMO, accuracy within ±1μm

- Surface roughness testing – Ra, Rz measurement down to Ra 0.02μm

- Material certification traceability – COA & RoHS/REACH compliance

- Ultrasonic cleaning in Class 1000 rooms – For particle-free delivery

✔ Global Project Experience: Trusted by Leading OEMs

In the past two decades, we’ve served Tier-1 semiconductor equipment manufacturers and integrators across Asia, Europe, and North America. Our delivered parts include:

- ✅ Multi-layer gas shower plates for a German PVD cluster tool manufacturer

- ✅ Alumina liners and ceramic rings for an American ICP-RIE system integrator

- ✅ Titanium electrode bases delivered to a Korean PECVD equipment provider

- ✅ Quartz shower heads for a Singapore-based wafer foundry group

We accept customer-provided drawings (2D/3D), and offer support from prototype to mass production with rapid lead times (5–15 working days typical).

✔ Why Global Semiconductor OEMs Trust Us

- ✔ 20+ Years CNC manufacturing exclusively for precision-critical industries

- ✔ Capability to machine ceramic, quartz, PEEK, titanium, aluminum with <±0.001mm tolerance

- ✔ Cleanroom-ready components with Class 1000 packaging

- ✔ Technical co-engineering support for new tool development

- ✔ Export to 30+ countries including Germany, USA, Israel, Japan, and Singapore

🔩 Let Us Support Your Etch & Deposition Equipment Projects

From 7nm to 2nm, precision is non-negotiable. Our expertise in ultra-high-precision machining enables us to support even the most advanced plasma and deposition tools.

📧 Contact our engineering team today to discuss your custom component requirements.