Precision CNC Parts for Strip Steel & Wire Forming Machines

Precision in Every Turn — Machined Components for Fine Wire & Strip Handling

From ultra-thin strip steel to high-speed welding wire, precision in forming, guiding, and coiling systems defines product quality and machine stability. Wire tangles, strip deformation, or poor alignment can compromise entire production runs.

Our CNC facility brings over 20 years of expertise in producing ultra-precise, wear-resistant, and dynamically balanced mechanical components for wire and strip processing systems across Europe, Asia, and the Americas.

✔ Challenges in Precision Wire & Strip Forming Components

- Micro-level accuracy: Wire straighteners and guide systems require dimensional control within ±0.005mm and concentricity better than 0.01mm.

- High-speed operation: Pulleys and rollers must be dynamically balanced to avoid vibration during 10,000+ RPM.

- Abrasion resistance: Continuous contact with hard steel wires demands hardened and polished surface finishes.

- Assembly repeatability: Modular roller blocks, tensioning arms, and guiding tracks must install with <0.01mm deviation.

- Tight groove tolerances: Wire path grooves must be precisely machined with controlled depth and roundness for accuracy and surface protection.

✔ Components We Machine for Wire/Strip Systems

| Component | Application | Features |

|---|---|---|

| Wire Guide Rollers / Pulleys | Feeding & coiling lines | CNC-turned, groove cut, hardened to HRC 58+ |

| Straightening Discs / Blocks | Multi-roller wire tensioners | Ra < 0.2μm, concentricity < 0.01mm, ±5μm bore fit |

| Forming Dies / Insert Bushings | Wire shape forming | Tool steel, lapped finish, interchangeable fit |

| Tension Arms & Pivot Brackets | Wire brake + loop control | Ground shafts, custom arms with bearing seats |

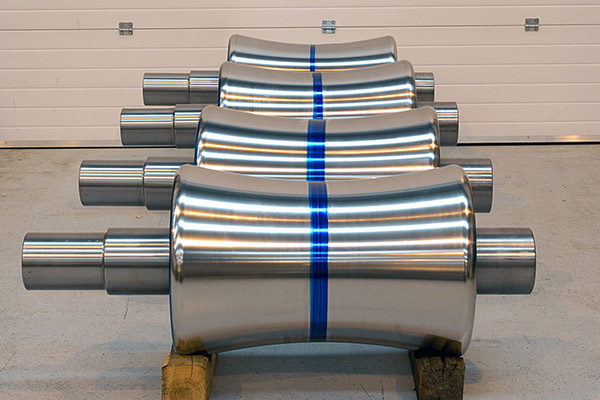

| Strip Steel Feed Rollers | Slitting/leveling machines | Nitrided or hard chrome, CNC-milled profile |

| Mandrels / Spindles / Coiling Shafts | Coil forming & take-up | Balanced shafts, multi-keyway, spline optional |

| Motor Base Frames & Supports | Wire draw/drive system | Bored + milled flat within ±0.01mm |

✔ Materials & Treatments

| Material | Typical Use | Treatments |

|---|---|---|

| Cr12MoV / D2 Tool Steel | Forming dies, wire guides | Vacuum heat-treated to HRC 60+ |

| 45# / 40Cr / 42CrMo4 | Pulleys, arms, shafts | Induction hardened, blackened, or chrome plated |

| Bronze / CuSn10 / CuZn37 | Low-friction bushings | Self-lubricating, with spiral grooves |

| Aluminum (6061, 7075) | Lightweight frame parts | Hard anodized, machined flat |

| SUS304 / 440C | Cleanroom wire delivery | Corrosion-resistant + polished |

Also available: PTFE coatings, ceramic inlays, and plasma nitriding for long-cycle wear components.

✔ Our CNC Capability Highlights

- Multi-groove turning (groove spacing ±0.01mm)

- Ultra-fine bore machining (tolerance ±0.005mm)

- Surface grinding (Ra 0.2–0.8μm)

- Dynamic balancing (for parts up to Ø400mm, 10,000 RPM)

- 4-axis simultaneous machining for complex forming units

- In-house fixture development for concentric assemblies

Inspection Equipment:

- CMM + profile projector

- Roundness tester and bore gauges

- Surface roughness meter (Ra < 0.2μm)

- Dynamic runout & vibration test station

- Microscopic groove profile measurement (on request)

✔ Global Client Projects

- ✅ Wire guide roller kits for high-speed welding wire feeder (Germany)

- ✅ Coiling mandrel and pulley assemblies for precision spring wire machine (Korea)

- ✅ Tension arm blocks + forming rollers for flat strip shaping machine (Turkey)

- ✅ Straightener die components for U.S. custom drawbench system (±0.005mm fits)

✔ Why Wire & Strip Equipment OEMs Choose Us

- 🧠 Deep know-how in ultra-precise rotating and wear parts

- 🧩 Flexible modular part kits: small batches or full assemblies

- 🛠 High-speed compatible components with vibration-free finish

- 🌐 Export-ready, trusted by Tier 1 clients in wire/strip forming

- 📦 One-stop solution: CNC + heat treatment + coating + balancing + QC

⚙️ Turning Accuracy into Productivity

Whether you’re feeding ultra-fine wire or shaping wide flat strip, our CNC precision ensures smooth motion, consistent tension, and exceptional surface handling.

📩 Contact us with your BOM and drawings — we’ll respond within 24 hours with tailored machining solutions.