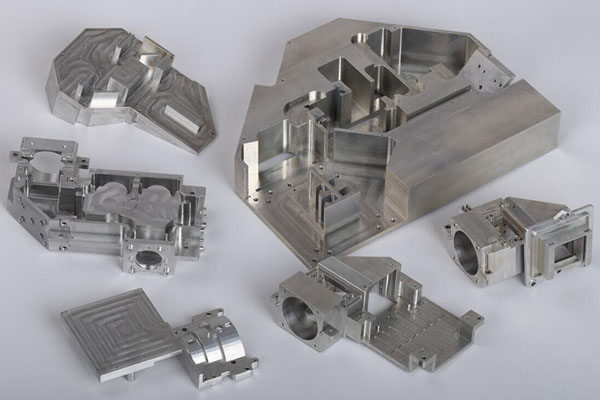

Precision CNC Machining for Construction Machinery & Automation Components

The construction machinery and automation industries demand robust, high-precision mechanical components capable of withstanding extreme loads, vibration, and continuous operation. From hydraulic actuator housings to robotic arm joints and gear transmission systems, these parts require ultra-tight tolerances and reliable structural integrity to perform consistently in harsh environments.

Key Machining Challenges:

- Heavy-duty material removal: Many components are made from high-strength alloy steels, tool steels, or wear-resistant castings that are difficult to machine.

- High-tolerance, large-volume parts: Components such as hydraulic cylinders, bearing housings, and planetary gears often require concentricity, perpendicularity, and surface roughness below 0.01mm.

- Complex geometries: Automated machinery parts often integrate undercuts, oil channels, or complex internal contours requiring simultaneous 5-axis machining or deep-hole drilling.

- Thermal distortion control: Long parts like actuator rods or guide rails need precise stress-relieving and finish grinding to avoid warping or heat-induced deformation.

Materials & Performance:

To meet the industry’s ruggedness requirements, we employ:

- Alloy steels (42CrMo, 40Cr, SCM440) for high tensile strength and impact resistance.

- Hardened tool steels (H13, D2) for wear-critical applications.

- Stainless steel (17-4PH, 316L) for corrosion resistance in automated food-grade or outdoor use.

- Aluminum 7075 and anodized grades for lightweight robotic or modular automation parts.

Each batch undergoes ultrasonic flaw detection, hardness testing, and dimensional validation to ensure fatigue life and structural performance.

Process & Quality Control:

Our factory, with over 20 years of CNC manufacturing experience, handles every stage with uncompromising quality:

- Rough & Finish Turning with Mazak and Doosan horizontal lathes

- Multi-Axis Milling using DMG Mori and Mikron 5-axis centers for precision contours

- ID/OD Grinding with Studer and Okamoto grinders for tolerances within 0.002mm

- Heat Treatment & Cryogenic Processing to stabilize parts before fine finishing

- Zeiss CMM, roundness testers, and contour tracers for full dimensional inspection

We maintain ISO 9001 and IATF 16949 certifications to support global OEM requirements.

Global Applications & Success Cases:

- Germany: Supplied hardened actuator pistons and gearboxes for tunnel boring machines.

- USA: Delivered stainless robotic arms for high-speed packaging lines.

- Japan: Provided cam-driven automation components with ±0.003mm accuracy for electronic assembly.

- Brazil: Manufactured hydraulic cylinder end caps with Ra0.4μm finish for off-road earthmovers.

Whether you require a one-off prototype or high-volume production, our CNC facility supports end-to-end engineering for your automation and construction machinery needs.