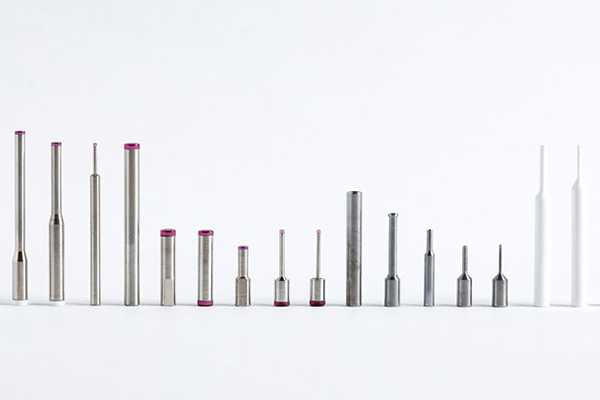

Precision Machining for Construction Machinery & Automation Components

In the field of construction machinery and industrial automation, the demand for high-strength, wear-resistant, and geometrically complex precision parts continues to rise. These components—including actuator housings, hydraulic motor shafts, robotic joints, and servo gear casings—must operate reliably under extreme loads, vibrations, and environmental challenges.

Machining Challenges:

The key difficulty lies in maintaining structural integrity while ensuring micro-level tolerances across large or irregular surfaces. Many parts require concentricity, perpendicularity, or flatness tolerances within ±0.002mm, despite their heavy mass or asymmetric design. Additionally, multi-surface synchronization in parts like cam followers or slewing bearings introduces significant complexity.

Material Applications:

We primarily process high-tensile steel (e.g., 42CrMo, 40CrNiMo), forged alloy steel, and wear-resistant cast iron. In automation, aluminum alloy (7075, 6061) and engineering plastics such as PEEK and PA66-GF30 are often adopted for lightweight but strong designs. Heat treatment and surface nitriding are often applied post-machining to improve component endurance.

Process Control & Technical Execution:

To meet such demanding specifications, we utilize advanced 5-axis machining centers (e.g., DMG Mori, Mikron) for multi-angle precision. Structural parts undergo rough turning and pre-milling on MAZAK and Doosan horizontal lathes, followed by STUDE flat/cylindrical grinding for critical fits. Geometric tolerances are verified using Zeiss CMM and Tokyo Seimitsu roundness testers. All parts are cleaned, deburred, and corrosion-proofed before shipment.

Production Highlights & Global Cases:

- Precision-manufactured piston rod systems for German hydraulic breaker manufacturers, featuring Ra0.2μm surface finish.

- Robotic arm reducers exported to a Japanese automation integrator, with internal gear concentricity held within 0.003mm.

- Large bearing housings for a Brazilian mining excavator project, ensuring parallelism of 0.005mm across a 600mm span.

Conclusion:

With over 20 years of experience in high-precision CNC machining, our factory has built a reputation for delivering mission-critical parts for global OEMs in construction and automation. From small-scale robot gears to large-scale excavation shafts, we provide stable, repeatable, and scalable manufacturing solutions trusted by partners in Germany, Japan, the U.S., and beyond.