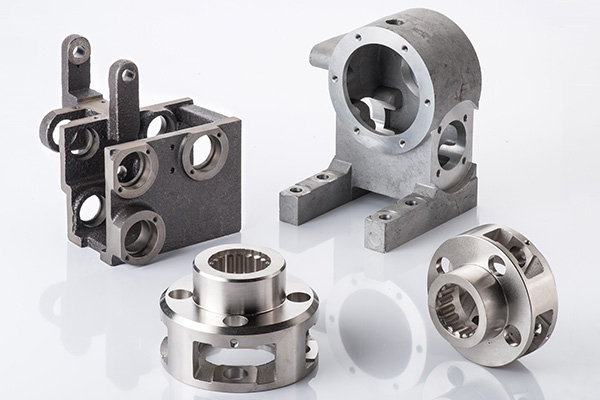

High-Precision CNC Machining for Automated Robotic Arm Joints in Construction and Automation Industry

Robotic arm joints, widely applied in automated production lines and smart construction equipment, demand the highest level of precision and reliability to ensure repetitive motion accuracy and long service life under high-speed or heavy-load conditions.

Machining Challenges

These components involve complex 3D geometries and tight tolerance fits, often requiring multi-surface synchronization and concentricity within ±0.003 mm. The rotational axis alignment and bearing housing surfaces are particularly critical, as even micro-deviations can result in mechanical play, affecting robot accuracy and lifespan.

Material Applications

High-strength steel alloys such as 42CrMo4 and hardened stainless steel (e.g., SUS440C) are commonly used. These materials provide superior wear resistance, fatigue strength, and corrosion protection, essential for robotic applications in harsh environments. For weight-sensitive automation arms, aerospace-grade aluminum (7075-T6) is also adopted, striking a balance between rigidity and lightness.

Process Control

Our CNC machining capabilities ensure precise dimensional and positional tolerances by combining:

- Five-axis simultaneous machining for complex curved surface coordination.

- Ultra-fine internal grinding of joint bores using STUDER grinders to achieve a roundness of ≤0.002 mm.

- Surface treatment processes such as hard anodizing or black oxide for corrosion protection and reduced friction.

- Precision honing and lapping for bearing interfaces to ensure smooth articulation without backlash.

All parts undergo full inspection with ZEISS CMM and Tokyoseimitsu roundness instruments, ensuring repeatable consistency across batches.

Equipment Deployed

- Mazak Integrex Multi-tasking Turning-Milling Center

- Mikron High-Speed 5-Axis CNC Center

- Studer S33 Internal/External Grinder

- Zeiss CMM & Surface Profilometer

- Ultrasonic Cleaning Line for Particle-Free Finish

Global Case Study

Our robotic joint components have been widely used by automation system integrators in Germany and Japan. One benchmark project involved supplying over 10,000 sets of arm joints to a European automotive automation company, where our components exceeded their durability testing requirements of 5 million cycles under continuous load.