China’s Strategic Edge in Precision Manufacturing: Steel Forming and Wire Shaping Solutions for Global Industries

As global industries evolve toward higher performance and tighter tolerances, the demand for precision-engineered components has never been more critical. In sectors such as steel forming and wire shaping—where structural integrity and dimensional consistency are paramount—China’s precision machining manufacturers have emerged as indispensable partners. Drawing on nearly two decades of experience, integrated engineering collaboration, and robust materials expertise, China is helping power the next generation of high-performance components for industries worldwide.

1. Engineering Collaboration from Concept to Production

One of the most underrated advantages of working with Chinese precision manufacturers lies in their early-stage involvement with design engineers. At the prototype and pre-production phases, our engineering teams offer deep technical insight into manufacturability, design feasibility, and process optimization. This collaborative approach ensures that wire forming tools, steel die sets, and complex forming components are not only produced accurately—but also optimized for durability, functionality, and long-term performance.

Unlike many regions where manufacturing begins only after the design is finalized, Chinese suppliers proactively engage in design-for-manufacturing (DFM) discussions, helping reduce iterative cycles and accelerating time-to-market.

2. Custom CNC Machining Based on Drawings

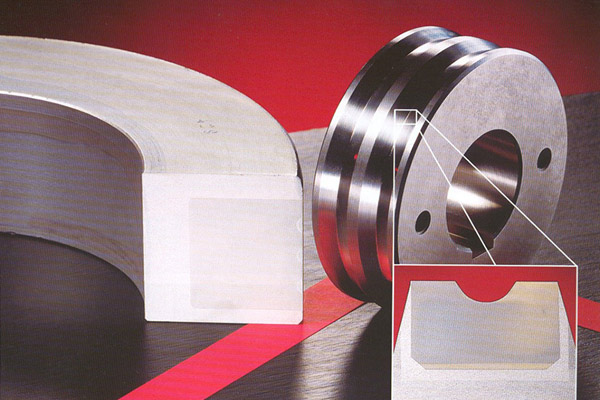

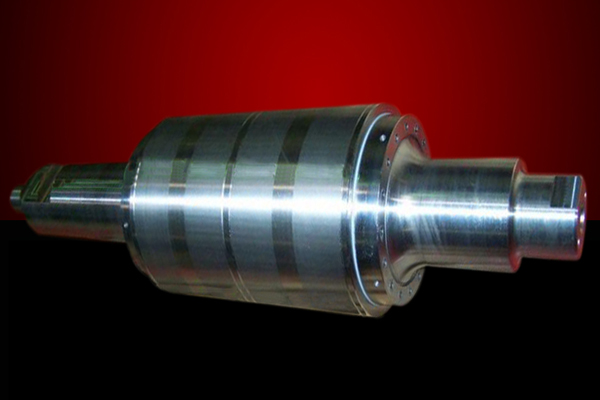

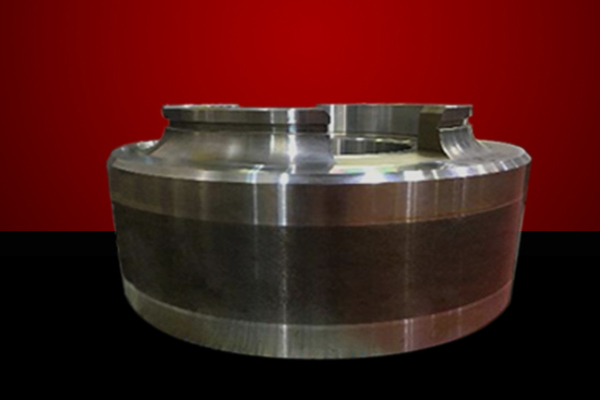

We specialize in custom CNC machining for a wide range of forming components including wire forming dies, straightening blocks, wire guides, steel rollers, and forming sleeves. Each part is tailored according to customer drawings, with tolerance control reaching ±0.001mm and surface finishes up to Ra0.2μm.

Whether you require one-off prototypes or full-scale production, we adapt our workflows to match your quality and volume needs—delivering not only custom parts, but engineered manufacturing solutions.

3. Materials Expertise Backed by Full-Chain Supply Integration

China’s robust materials ecosystem is a core strength in handling complex forming applications. We maintain long-term partnerships with domestic and international suppliers of premium-grade materials including:

- High-carbon steel and tool steel (e.g., SKD11, D2, H13)

- Stainless steel (e.g., SUS304, SUS316)

- Tungsten carbide and hard alloys for extreme wear resistance

- Heat-resistant alloys for hot forming dies

Our vertically integrated sourcing network ensures stable supply, fast lead times, and strict batch traceability—crucial for high-volume industrial production.

4. Process Optimization and Smart Manufacturing

With nearly 20 years of manufacturing experience, our team is adept at streamlining complex processes. From multi-axis CNC machining to precision surface grinding, EDM, and hard turning, every operation is tightly controlled. We apply digital simulation and CAM programming to minimize error and boost repeatability—especially important in forming parts subject to high stress or high cycle counts.

Our facilities are equipped with advanced quality inspection tools such as Zeiss CMMs, roundness testers, and profile projectors. Full-process quality control allows us to maintain geometric tolerances, concentricity, and wear resistance as per international standards.

5. On-Time Delivery and Global Customer Confidence

We understand that precision is nothing without reliability. That’s why we emphasize strong project management, consistent communication, and strict lead time discipline. Our manufacturing lead times are typically 25–40% faster than Western suppliers, without compromising on quality. We also provide full documentation including material certificates, inspection reports, and traceability records upon request.

Global clients in the automotive, construction, electronics, and hardware industries choose China not just for cost efficiency, but for the complete manufacturing ecosystem that supports speed, scale, and specialization.

Partner with China’s Precision Experts

From steel forming tools to custom wire shaping components, we deliver more than machined parts—we deliver solutions born of experience, collaboration, and precision. If you’re seeking a strategic manufacturing partner who understands your industry’s exacting demands, our team is ready to support you from design validation to final delivery.

Let’s build precision together.