Custom Fluid Control Parts CNC Machining – Precision Components for Pressure, Flow, and Reliability

Introduction: The Precision Imperative in Fluid Control Systems

Fluid control is a foundational technology across a wide range of industries, including oil & gas, water treatment, chemical processing, HVAC, food & beverage, and medical devices. Whether handling aggressive chemicals, high-pressure steam, or sterile gases, fluid systems must operate with absolute reliability.

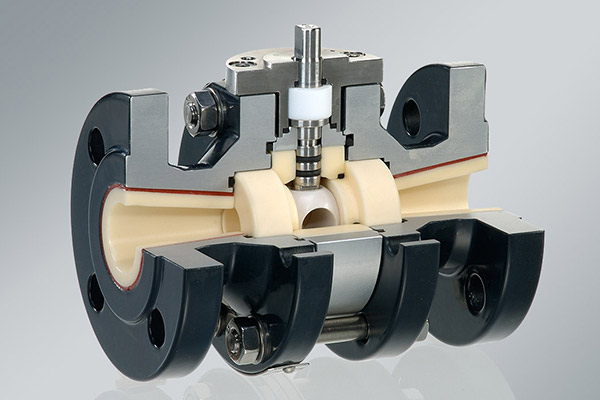

At the heart of these systems lie precision-engineered components—valves, fittings, sleeves, manifolds, and housings—that must maintain tight tolerances and seal integrity under extreme conditions. As a trusted partner in custom fluid control parts CNC machining, we deliver high-performance parts tailored to your exact drawings and functional requirements.

Machining Challenges and Our Solutions

Fluid control components face a unique combination of mechanical, chemical, and thermal challenges:

- Tight Tolerances for Sealing Performance: Valves, orifices, and precision bores require dimensional accuracy down to microns to ensure leak-free operation.

- Corrosion and Chemical Resistance: Many systems transport caustic or reactive media, demanding materials like stainless steel, titanium, or high-performance polymers.

- Pressure and Temperature Variability: Parts must perform reliably under fluctuating pressure ranges and extreme temperatures, requiring durable construction and surface integrity.

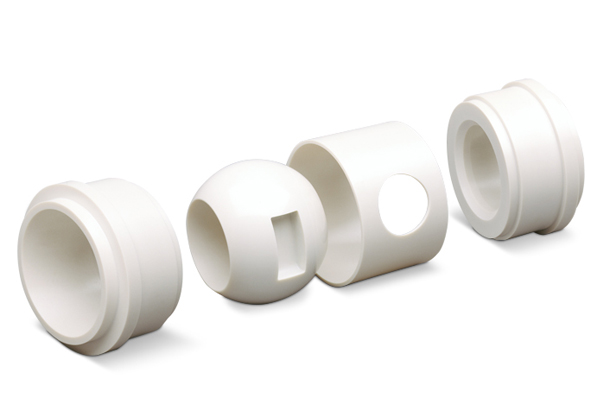

- Complex Internal Features: Valve bodies, flow regulators, and manifold blocks often have intricate internal geometries—deep bores, cross-holes, and internal threads—necessitating multi-axis CNC machining.

Our Solution:

We use a combination of high-speed milling, precision turning, and deep-hole drilling supported by advanced 4-axis and 5-axis CNC machining centers. Our engineering team works closely with clients to evaluate tolerances, material suitability, and manufacturing feasibility. From prototype to production, every part is machined to exact specifications, thoroughly inspected, and delivered contamination-free for immediate integration.

Common Materials and Their Characteristics

To meet the requirements of diverse fluid control environments, we machine a variety of corrosion-resistant metals and performance plastics:

- Stainless Steel (304, 316L, 321, 17-4PH): Excellent corrosion resistance and strength; ideal for sanitary valves, flow bodies, and fittings in aggressive environments.

- Brass and Bronze (C360, C932): Good machinability and sealing properties; used in low- to medium-pressure applications like water and gas valves.

- Titanium (Grade 2, Grade 5): Lightweight and highly resistant to chemical corrosion, commonly used in medical and offshore fluid systems.

- Aluminum Alloys (6061, 7075): Lightweight and corrosion-resistant, ideal for flow control modules in HVAC, instrumentation, and packaging machinery.

- Engineering Plastics (PTFE, PEEK, PVDF): Chemically inert and heat-resistant, perfect for valve seats, seals, and low-friction flow components.

- Hastelloy, Monel, Inconel: High-performance alloys for critical environments such as acid processing and high-temperature steam.

Material traceability, certification (e.g., RoHS, REACH, ASTM), and treatment processes such as passivation or anodizing are available upon request.

CNC Machining Capabilities

We specialize in high-precision custom CNC machining for fluid control parts, delivering exceptional accuracy, repeatability, and surface finish:

- Tolerances and Finishing:

- Dimensional tolerance: ±0.001mm

- Roundness and concentricity: ≤0.002mm

- Surface finish: Ra 0.1–0.4μm depending on sealing and flow requirements

- Machining Equipment:

- Mazak CNC Turning Centers: Perfect for turning valve stems, ferrules, connectors, and thread-in components

- Mikron CNC Milling Machines: For precision flow bodies, manifold blocks, and complex valve housings

- Studer CNC Grinders: Ensure ultra-flat and concentric sealing surfaces

- Deep-hole drilling & cross-hole milling: Used in fluid manifolds and pressure control systems

- Zeiss CMM & Roundness Testers: 100% inspection of critical geometry and form

- Supplementary Capabilities:

- Surface treatments: Electropolishing, passivation, anodizing, nickel/chrome plating

- Cleaning & packaging: Ultrasonic cleaning, cleanroom packaging for medical/food-grade components

- Documentation: Full PPAP, material certificates, dimensional reports, and traceability records

Common Fluid Control Parts and Their Applications

We manufacture a broad range of CNC machined parts for fluid control systems, each built to the customer’s CAD files, 2D drawings, or samples:

- Valve Bodies and Sleeves: Machined from stainless steel, brass, or titanium for pressure, gas, and fluid valves

- Manifold Blocks and Housings: Precision-drilled and milled to accommodate internal flow paths, sensor ports, and fittings

- Orifice Plates and Discs: Ultra-flat flow restriction elements with polished surfaces for minimal pressure loss

- Stems, Pistons, and Spools: Key components in pressure regulators and directional control valves

- Seal Retainers and Valve Seats: Machined from PEEK or PTFE to ensure chemical compatibility and wear resistance

- Threaded Adapters and Flanges: CNC-turned with sealing threads and surface finish optimized for O-ring or metal-to-metal sealing

Each part is designed and machined to support critical systems in industries like water purification, fuel control, chemical dosing, food dispensing, and industrial automation.

Project Highlight

A recent project involved CNC machining a series of 316L stainless steel valve bodies for a medical-grade oxygen flow control system. The parts required cross-drilled channels, mirror-polished sealing surfaces (Ra 0.1μm), and full ultrasonic cleaning before Class 1000 cleanroom packaging. Dimensional inspection confirmed ±0.002mm tolerance across all functional features. The customer successfully integrated the parts into life-saving ventilator systems during peak demand.

Your Precision Partner in Fluid Control Machining

With years of experience in custom fluid control parts CNC machining, we support clients across multiple industries with high-precision, high-performance components. From flow valves in harsh chemical environments to food-grade liquid dispensing systems, we deliver parts you can trust—accurate, durable, and application-ready.

Contact us today to request a quote, share your drawings, or discuss your specific fluid control application needs. Our CNC experts are ready to support your project from prototype to production.