Custom Food, Beverage, and Packaging Components + CNC Machining — Precision Solutions for a Hygiene-Critical Industry

Introduction: Precision Parts for a Hygiene-Critical Industry

In the food, beverage, and packaging industries, precision, reliability, and compliance with sanitary standards are non-negotiable. Every part that comes into contact with consumables must meet exact tolerances, resist corrosion, and conform to food-grade safety standards. From processing lines and bottling machines to automated packaging systems, the demand for custom food, beverage, and packaging components + CNC Machining has never been higher.

As automation accelerates and hygiene regulations tighten, manufacturers increasingly rely on CNC machined components tailored to their specific equipment. These custom components ensure consistent production, reduce contamination risks, and minimize costly downtime.

Machining Challenges and Our Solutions

Machining components for the food, beverage, and packaging industries poses a unique set of challenges:

- Food Safety and Material Compliance: Components must be machined from certified food-grade materials such as 316L stainless steel or FDA-compliant plastics like PEEK and PTFE. Surface finishes must be smooth and free of crevices where bacteria can accumulate.

- Precision for Interchangeability: Automated lines demand ultra-precise parts that maintain alignment and perform consistently at high speeds.

- Wear, Moisture, and Chemical Resistance: Components are regularly exposed to water, cleaning agents, acids, and oils. Machining and finishing must support long-term durability under these conditions.

- Short Turnaround and Part Customization: OEMs and maintenance teams often require one-off or small-batch parts with rapid lead times and strict tolerance requirements.

Our Solution:

We specialize in CNC machining of food and packaging components using certified hygienic materials, advanced 5-axis equipment, and precision inspection. We deliver ±0.01mm or better tolerances and ensure all surfaces are polished to Ra 0.4μm or smoother, meeting sanitary requirements. With full CAD/CAM support, we can manufacture from your drawings or reverse engineer from existing parts.

Common Materials and Their Characteristics

To ensure safety and reliability, we select materials specifically suited to the food and packaging environment:

- Stainless Steel (304, 316, 316L): Corrosion-resistant, heat-tolerant, and ideal for parts in direct food contact. 316L is particularly popular due to its improved resistance to acidic and saline environments.

- PEEK (Polyether Ether Ketone): A high-performance thermoplastic with excellent chemical resistance and FDA compliance. Common in bushings and seals.

- PTFE (Teflon): Non-stick and low-friction material used for gaskets, valve seats, and insulating parts.

- Aluminum Alloys (6061, 7075): Lightweight and easy to machine; used for structural components and non-contact mechanisms.

- Acetal (Delrin): FDA-approved engineering plastic with low moisture absorption and high dimensional stability.

All materials are traceable and come with certification for compliance with FDA, EU 1935/2004, or equivalent regulations upon request.

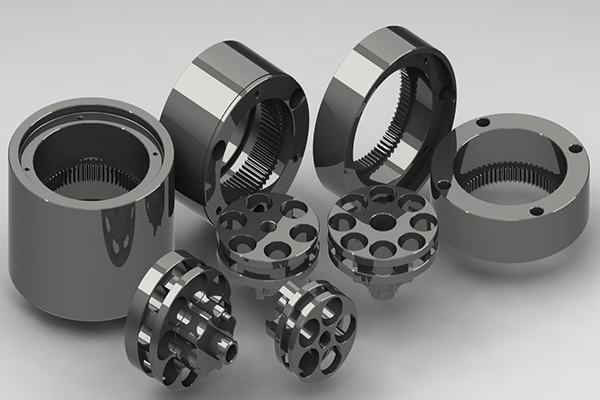

CNC Machining Capabilities

Our facility is fully equipped to meet the demands of hygiene-focused industries:

- Tolerances & Surface Finish:

- Dimensional tolerances: ±0.005mm to ±0.01mm

- Surface roughness: down to Ra 0.2–0.4μm (food-grade polishing standard)

- Key Equipment and Capabilities:

- 5-Axis CNC Milling and Turning Centers: For producing complex geometries in a single setup

- Swiss-Type Lathes: Ideal for high-precision small diameter components

- CNC Grinding & Polishing: For shafts, rollers, and sealing surfaces

- High-Speed Drilling and Tapping: For components requiring rapid flow and fastening points

- 3D Coordinate Measuring Machine (CMM): Full QA inspections and documentation

- Post-Processing Services:

- Electropolishing for improved corrosion resistance

- Anodizing (for aluminum parts not in direct contact with food)

- Ultrasonic cleaning before packaging

- Assembly and sub-component integration

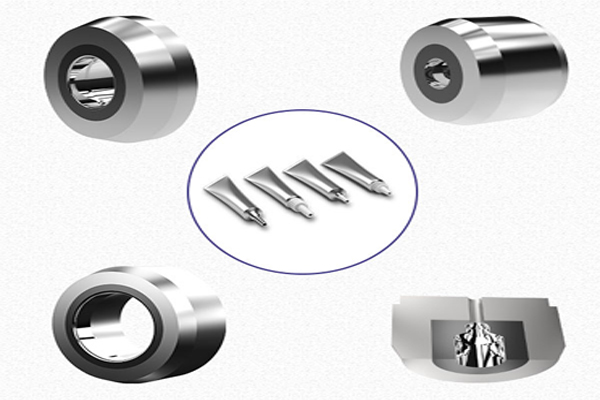

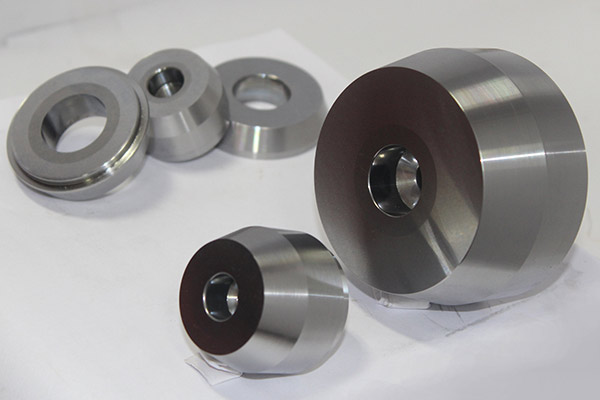

Common CNC Machined Parts and Their Applications

We provide a broad range of custom food, beverage, and packaging components + CNC Machining for a wide variety of production lines and processing systems:

- Filling Nozzles & Dispensing Valves: Engineered for exact flow rates and leak-free operation

- Guide Rails & Conveyor Components: Wear-resistant and dimensionally stable under fast movement

- Hopper & Mixer Shafts: CNC ground for high concentricity and balanced rotation

- Sealing Rings & Retainer Flanges: Produced with low-friction materials to ensure hygienic sealing

- Forming Plates & Punch Dies: Customized to specific product geometry for packaging automation

- Bottle Handling Parts, Grippers, and Indexers: Critical in bottling lines for high-speed orientation and movement

- Inspection & Sensing Mounts: Precision brackets for cameras and sensors used in quality control

These components are essential for reducing cross-contamination, maintaining uptime, and ensuring consistent quality across batches.

Project Highlight (Optional)

We recently completed a CNC machining project for a client in the dairy processing industry requiring custom stainless steel filling valves and rotating shaft assemblies. The parts were made from 316L stainless steel, machined to ±0.005mm tolerance, and electropolished to a final surface roughness of Ra 0.3μm. The client reported significant improvements in CIP (Clean-In-Place) performance and reduced bacterial adhesion.

Partner with a Trusted CNC Specialist for Custom Food and Packaging Components

With strict hygiene standards, tight deadlines, and the need for repeatable accuracy, the food and packaging industry requires a machining partner that understands both compliance and complexity.

We are your trusted source for custom food, beverage, and packaging components + CNC Machining, with the technology, expertise, and responsiveness to meet your exact needs.

Contact us today to share your 2D drawings or 3D models and receive a fast, competitive quote. Let us help you keep your production lines moving — clean, safe, and precise.

Embedded SEO Keywords:

custom food, beverage, and packaging components + CNC Machining, FDA-compliant plastics CNC, food-grade stainless steel machining, 5-axis CNC for food machinery, ±0.01mm tolerance food components, Ra 0.4μm surface finish CNC, hygienic part machining, CNC components for packaging automation