Custom Key Parts for Steel Production + CNC Machining – Precision Components for Heavy-Duty Industrial Applications

Introduction: The Critical Demand for Precision in Steel Production Components

Steel production is an industry where reliability, strength, and precision engineering converge. The machinery and equipment used in steel mills operate under extreme conditions—high temperatures, heavy loads, and continuous operation—that demand robust and highly precise components. From rolling mills to forging presses, every key part must meet stringent quality and dimensional requirements to ensure optimal performance and longevity.

As specialists in custom key parts for steel production + CNC Machining, we provide tailored solutions that deliver the strength, precision, and durability steel plants require. Our components help keep steel production lines running smoothly and efficiently, minimizing downtime and maximizing output quality.

Machining Challenges and Our Solutions

Manufacturing parts for steel production involves several complex challenges:

- Handling Large and Heavy Components: Parts such as rollers, shafts, and housings often have significant dimensions and mass, requiring specialized CNC equipment and handling.

- High-Temperature and Wear-Resistant Requirements: Components must withstand harsh thermal cycles and abrasive wear, influencing material choice and machining processes.

- Complex Geometries and Tight Tolerances: Critical parts like spindle shafts, coupling flanges, and guide rollers require multi-axis machining with tolerances often within ±0.01mm or tighter.

- Surface Integrity and Fatigue Resistance: Surface finishes and treatments must minimize fatigue, prevent corrosion, and maintain mechanical integrity under continuous stress.

Our Solution:

We employ heavy-duty CNC lathes, 5-axis milling centers, and precision grinding machines capable of working on large-scale steel parts. Our engineering team collaborates closely with customers to optimize designs for manufacturability and endurance. We also integrate advanced inspection technologies and apply surface treatments to enhance performance.

Common Materials and Their Characteristics

The demanding environment of steel production calls for robust materials known for strength, wear resistance, and thermal stability:

- Alloy Steels (4140, 4340): High tensile strength and toughness; commonly used for shafts, gears, and structural parts.

- Carbon Steels (C45, C60): Cost-effective and machinable steels suitable for moderate wear resistance components.

- Tool Steels (D2, H13): Employed in parts requiring high hardness and wear resistance, such as dies and rollers.

- Stainless Steels (304, 316): Used for corrosion-resistant parts exposed to humid or chemical environments within steel plants.

- Cast Iron: Sometimes used for heavy housings and structural components due to vibration damping properties.

Materials are carefully selected based on application requirements, and can undergo heat treatment, nitriding, or surface coating to enhance wear resistance and lifespan.

CNC Machining Capabilities

Our machining capabilities cater specifically to the challenging needs of steel production parts:

- Precision and Tolerances:

- Dimensional tolerances: ±0.005mm to ±0.02mm depending on part function and size

- Surface finish: Typically Ra 0.8–3.2μm, with finer finishes achievable for sealing surfaces

- Equipment Highlights:

- Heavy-Duty CNC Lathes: Capable of machining large diameter shafts and rollers

- 5-Axis CNC Milling Centers: For complex housings, flanges, and multi-surface parts

- CNC Grinding Machines: Achieving fine surface finishes and critical geometric tolerances

- Coordinate Measuring Machines (CMM): 3D inspection ensuring conformity to stringent specs

- Additional Processing:

- Heat treatments such as quenching and tempering

- Surface treatments like nitriding and chrome plating for wear resistance

- Balancing and dynamic testing services for rotating components

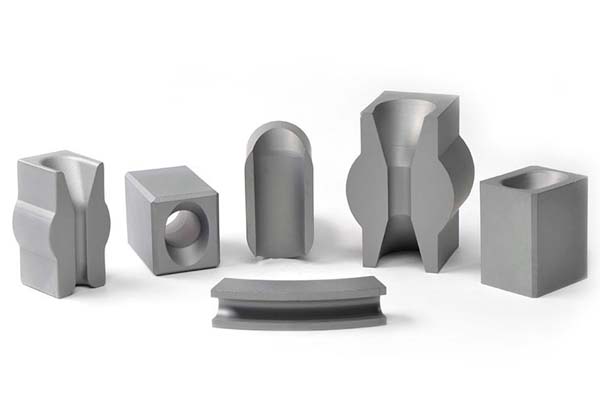

Common CNC Machined Parts and Their Applications in Steel Production

Our CNC machining solutions cover a broad range of critical steel mill components, including:

- Rollers and Roll Shafts: Precision ground to exact diameters and tolerances for uniform metal forming

- Spindle Shafts and Couplings: Engineered for strength and alignment accuracy in rolling stands and processing lines

- Gear Housings and Bearing Blocks: Machined from alloy steel or cast iron for structural support and durability

- Wear-Resistant Tooling Components: Such as forming dies, guides, and clamps designed for heavy abrasion environments

- Hydraulic and Pneumatic Cylinders: Precision machined parts that control mill operations with tight fit and leak-proof seals

These parts are essential to maintain the continuous and efficient operation of steel production facilities, reducing maintenance intervals and production interruptions.

Project Highlight

A recent project involved CNC machining a set of alloy steel rollers for a major steel rolling mill. The parts required tight dimensional tolerances of ±0.005mm, precision balancing, and surface hardness achieved through nitriding. After machining and heat treatment, the rollers underwent comprehensive inspection with CMM and surface roughness testing before being installed. The customer reported improved product consistency and extended maintenance cycles.

Your Trusted Partner for Custom Steel Production Components

When it comes to custom key parts for steel production + CNC Machining, experience, precision, and reliability are non-negotiable. We combine advanced CNC machining technologies with in-depth metallurgical expertise to provide parts that meet the rigorous demands of steel manufacturing.

Contact us today to share your drawings, discuss material options, and receive a competitive quote. Let us help you enhance your steel production efficiency with precision-engineered CNC machined components.

Keywords naturally embedded: custom key parts for steel production, CNC Machining, alloy steel machining, heavy-duty CNC lathe, 5-axis milling for steel parts, precision rollers machining, nitriding surface treatment, steel mill components CNC, tight tolerance machining.