Custom Optical Components CNC Machining – High-Precision Parts for Vision, Sensing & Photonics

Introduction: Why Precision Matters in the Optics Industry

Optical systems—ranging from high-resolution imaging devices to laser equipment, LiDAR sensors, and scientific instruments—depend on ultra-precise mechanical components to ensure accurate light transmission, reflection, focusing, and alignment. Even the smallest dimensional deviation in optical housings or mounts can cause signal distortion or functional failure.

This is why leading photonics companies, instrument makers, and optical system integrators require highly specialized custom optical components CNC machining services. Each part must meet stringent tolerances, ultra-smooth surface finishes, and optical-grade alignment standards—delivered clean, consistent, and ready for assembly.

Machining Challenges and Our Solutions

Optical components are among the most demanding in terms of tolerances, surface finish, and alignment geometry. Key challenges include:

- Extreme Tolerances: Most optical components require dimensional tolerances of ±0.002mm or better, especially for lens mounts, mirror holders, and beam splitters.

- Ultra-Smooth Surface Finish: Flatness and roughness affect how light is reflected or transmitted. Many parts require finishes down to Ra 0.05μm or better.

- Material Sensitivity: Many optical components are made from soft aluminum alloys, brass, or engineering plastics that require gentle, high-precision machining.

- Complex Geometries: Multi-axis milling is needed for elliptical contours, lens nests, alignment notches, and internal pockets with tight tolerances.

- Cleanroom Compatibility: Components often go directly into optical assemblies and must be free of contamination, particles, or machining residue.

Our Solution:

We offer ultra-precision 4-axis and 5-axis CNC machining, micro-milling, and surface polishing specifically tailored for optical-grade parts. Our team works closely with engineers to optimize each design for manufacturability and performance. From one-off prototypes to high-volume batches, we ensure every component meets or exceeds industry optical standards.

Common Materials and Their Characteristics

We work with a wide range of materials selected for their mechanical stability, low reflectivity, corrosion resistance, and compatibility with optical assemblies:

- Aluminum Alloys (6061-T6, 7075, 2024): Lightweight, excellent machinability, often anodized black for anti-reflective coatings in optical housings.

- Brass (C360, C260): Dimensional stability and non-magnetic properties make it ideal for lens holders and alignment mechanisms.

- Stainless Steel (304, 316, 17-4PH): High strength and corrosion resistance for structural optical parts or components in harsh environments.

- Titanium (Grade 5): Strong yet lightweight, ideal for aerospace or high-end optics with vibration-sensitive applications.

- Engineering Plastics (PEEK, Delrin/POM, PTFE): Used for lightweight, low-friction or dielectric parts such as spacers, lens retainers, and precision guides.

- Black Anodized Surfaces: We commonly finish optical aluminum components with black anodizing to reduce stray light and improve thermal management.

Each material is selected according to your design requirements, including coefficient of thermal expansion, reflectivity, and assembly compatibility.

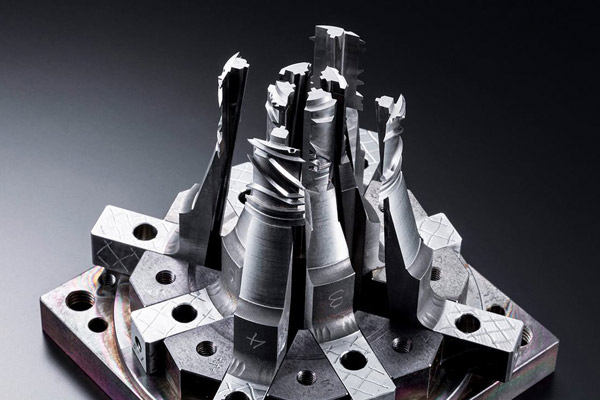

CNC Machining Capabilities

As a specialist in custom CNC machining for optical components, we maintain advanced facilities and meticulous quality systems to guarantee consistency, precision, and cleanliness.

- Precision Capabilities:

- Dimensional tolerances: ±0.001–0.002mm

- Surface finish: Ra 0.05–0.2μm, optical-grade as needed

- Flatness, concentricity, parallelism: Verified to micron-level accuracy

- Equipment Highlights:

- Mikron 5-axis CNC Milling Centers: For complex geometries and ultra-fine feature control

- Mazak CNC Lathes: Ideal for round optical parts, mounts, threaded retainers

- Studer CNC Grinding: Ultra-precise grinding of flat or cylindrical surfaces

- Zeiss CMMs & Optical Profilers: Metrology-grade inspection for profile, flatness, and concentricity

- Cleanroom-ready packaging line: To meet optical assembly cleanliness requirements

- Optional Services:

- Black anodizing (Type II and Type III)

- Laser engraving for part identification

- Ultrasonic cleaning and Class 1000 packaging

- Machined alignment reference marks or dowel pinholes for precision assembly

We provide First Article Inspection (FAI), full dimensional reports, and material certifications upon request.

Common Optical Components We Machine

We produce a wide variety of custom CNC machined optical parts, including:

- Lens Mounts and Holders: Precision bores and concentric threads to secure and align optics

- Optical Benches and Platforms: Structural components with flatness and stiffness for laboratory or production setups

- Mirror Housings and Adjustment Frames: Often black anodized with micrometer positioning capability

- Laser and Beam Splitter Assemblies: CNC-machined modules that guide and direct laser paths

- Sensor and Camera Mounts: Machined with tight positional tolerances and lightweight structures for high-speed imaging

- Retaining Rings and Spacer Shims: Thin-wall precision rings that hold optics in fixed axial positions

All components are produced based on your CAD drawings or specifications, optimized for downstream assembly, thermal behavior, and long-term performance.

Project Highlight

We recently partnered with a European photonics startup to manufacture a series of aluminum optical mounts with critical lens seating surfaces machined to Ra 0.05μm. These parts featured custom alignment holes, dual-axis adjustment slots, and a black anodized finish for anti-reflection. The batch was delivered within 10 working days, fully inspected, cleaned, and packaged in anti-static foam trays for cleanroom assembly.

Let’s Bring Precision to Your Optical Design

Whether you’re developing a precision microscope, building next-gen LiDAR sensors, or constructing a photonics testing platform, our custom optical components CNC machining services ensure you get the precision your application demands.

Contact us today to discuss your project, upload your 3D files or drawings, and receive a custom quote. Our team is ready to support you from prototype to production—on time, on spec, and with optical-grade quality you can trust.