Expert CNC Machining for High-Precision Global Applications

In today’s global manufacturing landscape, the demand for high-precision CNC machining has surged, driven by industries such as aerospace, medical devices, automotive, and electronics. Chinese CNC machining manufacturers have increasingly positioned themselves as reliable partners for international clients seeking complex, high-accuracy components. Their ability to deliver tailored solutions, handle challenging materials, and navigate intricate design specifications has made them essential players in the global supply chain. This article explores how expert CNC machining services from China meet the rigorous demands of high-precision applications worldwide, emphasizing customization, advanced material processing, and the importance of extensive experience.

Precision CNC Machining for Global High-Precision Manufacturing Needs

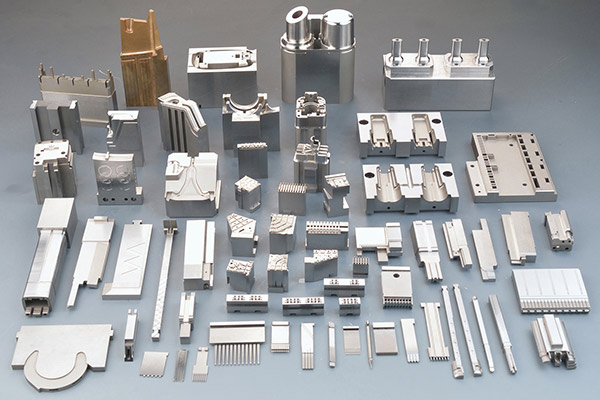

Chinese CNC machining companies have built a reputation for providing precise, high-quality parts that meet the stringent standards of global industries. This is achieved through advanced equipment, meticulous quality control, and a deep understanding of complex design requirements. The capacity to produce micro-sized, intricate components — often with tolerances within microns — makes these manufacturers ideal for sectors where accuracy is critical, such as aerospace and medical technology. Their ability to adapt to diverse project specifications ensures that clients receive products that perform reliably under demanding conditions.

Furthermore, these manufacturers excel in handling a wide range of materials, including metals like titanium, stainless steel, aluminum, and even specialized composites. Each material presents its own challenges in terms of machining and finishing; thus, the expertise to process them effectively is essential. The integration of CAD/CAM technologies and precision measurement tools ensures that every component adheres to exact specifications, reducing waste and optimizing efficiency. This level of precision and consistency fosters trust among international customers who rely on the integrity of each part for their critical applications.

The global landscape features a variety of complex machining challenges, such as creating micro holes, threaded inserts, or intricate geometries on difficult-to-machine materials. Chinese CNC providers have proven their capability by successfully tackling projects that demand ultra-fine precision and complex tolerances. For example, high-precision aerospace components with complex internal channels or medical implants with micro-detailing are routinely manufactured with exceptional quality. These achievements underscore the importance of advanced equipment coupled with skilled craftsmanship in overcoming the most demanding manufacturing obstacles worldwide.

Custom Solutions and Expertise in Complex Material Processing

One of the key strengths of Chinese CNC machining manufacturers is their ability to offer customized solutions tailored precisely to client specifications. This involves not just manufacturing parts, but also collaborating closely during the design phase to optimize manufacturability and cost-effectiveness. Such consulting expertise ensures that complex designs are translated into feasible production plans, reducing lead times and minimizing errors. For high-precision applications, this partnership approach ensures the final product meets all functional and dimensional requirements.

Handling challenging materials is another critical aspect of their expertise. Materials like titanium alloys, zirconia ceramics, and high-performance polymers require specialized tooling, cutting strategies, and finishing techniques. These materials are often used in extreme environments, such as aerospace or medical implants, where reliability is paramount. Chinese manufacturers have invested heavily in developing processing techniques for these materials, enabling them to produce components with tight tolerances and superior surface finishes. Their experience in this area ensures high-quality results even with the most difficult-to-machine substances.

Global case studies further illustrate their proficiency in solving complex machining problems. For instance, manufacturing micro-sized medical devices with intricate internal structures on titanium alloys or producing aerospace components with multi-layered geometries has demonstrated their capability to handle difficult challenges. These cases often involve overcoming issues such as tool wear, thermal distortion, or micro-cracking, requiring extensive technical knowledge and adaptive strategies. The accumulated experience in tackling such “hard-to-machine” materials and designs makes Chinese CNC suppliers invaluable partners for international high-precision manufacturing projects.

OUTRO:

As the demand for high-precision, complex components continues to grow across industries worldwide, Chinese CNC machining manufacturers stand out as trusted partners capable of delivering customized, high-quality solutions. Their expertise in processing difficult materials, handling intricate designs, and maintaining tight tolerances ensures they meet the rigorous standards set by global clients. By combining advanced technology with years of experience in overcoming manufacturing challenges, these firms empower industries to innovate and excel. Ultimately, their ability to provide expert CNC machining services on a global scale underscores the critical role of precision manufacturing in shaping the future of high-tech innovation.