High-Precision Ceramic Components for Power Electronics & High-Voltage Insulation

±0.001mm tolerances | Excellent dielectric strength | Engineered for high-voltage, high-frequency reliability

In the rapidly evolving world of power electronics and energy infrastructure, ceramic components play an essential role in electrical insulation, thermal management, and dimensional stability under extreme voltage and current loads. From electric vehicles to power grids, from inverters to HVDC systems, technical ceramics ensure safety, efficiency, and long-term reliability.

With 20+ years of experience in custom ceramic machining, we manufacture components with micron-level tolerances and proven dielectric performance for the most demanding power applications.

Ceramic Advantages for Electrical & High-Voltage Systems

We machine a wide range of high-performance ceramics such as:

- Alumina (Al₂O₃) – up to 99.8% purity, excellent dielectric strength

- Steatite & Cordierite – used in traditional power devices and insulating bushings

- Aluminum Nitride (AlN) – high thermal conductivity with electrical insulation

- Macor® & Zirconia – for special electrical/thermal hybrid assemblies

These ceramics provide:

- Dielectric strength >15kV/mm

- Low dielectric loss at high frequency

- Stable performance from -50°C to +1000°C

- Non-magnetic, low-outgassing, and arc-resistant surfaces

- High surface resistance and volume resistivity

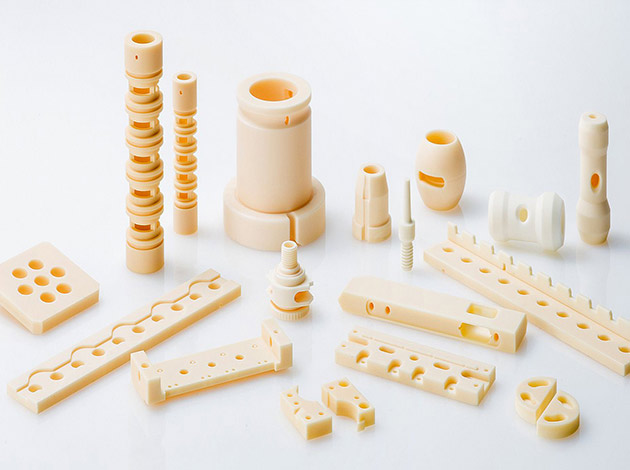

Components We Typically Manufacture

- Insulating rings, tubes, and sleeves for HV connectors

- Ceramic isolators for vacuum interrupters and switches

- Substrates for IGBT, SiC, and GaN power modules

- Spacer discs and terminal insulators

- Feedthrough insulators for battery or inverter enclosures

- Heatsink baseplates with electrical isolation

- Arc-resistant ceramic bushings for power distribution systems

Applications include:

✔ EV charging infrastructure

✔ Power inverters and UPS systems

✔ High-voltage switchgear and circuit breakers

✔ Power converters for solar/wind energy

✔ HV battery modules and BMS systems

✔ Smart grid and substation equipment

Ultra-Precision Processing for Dielectric Components

We use:

- CNC and diamond grinding systems capable of ±0.001mm tolerance

- Surface lapping and polishing for connector-grade interfaces (Ra ≤ 0.02μm)

- Concentricity and roundness control ≤0.002mm for rotating or sealing insulators

- Electrical breakdown testing and dielectric validation on request

Our metrology lab ensures full compliance with electrical, dimensional, and geometric standards required for high-voltage reliability.

Engineering Support for Critical Power Systems

We assist global energy customers in:

- Drawing review and co-design for improved dielectric spacing and creepage

- Material selection based on thermal dissipation, partial discharge resistance, and high-purity requirements

- Prototyping for new insulation systems or high-frequency PCB supports

- Providing full traceability, RoHS/REACH declarations, and material certification

- Delivering both custom 1-off parts and batch production at scale

Global Project Footprint

Our ceramic parts are trusted in:

- European and Asian EV charging platforms (DC fast-charging insulators)

- American-made HV switchgear and inverters

- Solar farm transformer interfaces and isolators

- Battery-powered rail transit insulation solutions

- Grid-level energy storage and distribution systems

Insulate. Isolate. Protect — with Ceramic Precision

From kilovolts to gigawatts, the energy revolution depends on reliable insulation and component stability. Our high-purity ceramic parts are machined for performance, precision, and peace of mind—even under the harshest electrical loads.

Let’s electrify the future—safely and precisely, one ceramic part at a time.