High-Precision CNC Machining for Custom Parts in the Food, Beverage, and Packaging Industry

Precision Demands in Food, Beverage & Packaging Equipment

The food, beverage, and packaging industry operates under intense regulatory, hygienic, and performance standards. From automated filling lines to industrial mixers and sealing systems, every machine relies on high-precision custom components that must deliver consistent accuracy, resist corrosion, and comply with food safety guidelines.

As processing speeds increase and hygiene standards tighten, manufacturers are turning to CNC machining for food, beverage, and packaging high-precision custom parts. These components are vital for the smooth and sanitary operation of modern equipment across bottling plants, dairy facilities, commercial kitchens, and packaging factories.

Manufacturing Challenges and CNC Machining Solutions

The industry’s unique requirements create several engineering challenges for part production:

- Sanitary Compliance: All components that come into contact with food or beverage must be easy to clean, corrosion-resistant, and made from FDA-compliant materials.

- High Wear and Tear: Continuous motion, high-speed cutting, and abrasive ingredients can quickly degrade inferior parts.

- Dimensional Accuracy: For parts like valves, nozzles, and sealing heads, even small tolerances can affect filling accuracy, cause product leakage, or lead to contamination.

- Customization Needs: Equipment often requires specialized or non-standard components that must be adapted to proprietary designs or process flows.

Our high-precision CNC machining services are tailored to meet these challenges. We utilize multi-axis CNC milling and turning, combined with electropolishing, surface passivation, and custom fixture setups, to manufacture parts that meet both sanitary and mechanical performance standards.

Common Materials for CNC Machined Food & Beverage Components

Material selection is critical in the food, beverage, and packaging industry, where safety, resistance to corrosion, and cleanability are non-negotiable. We work with materials that comply with FDA, USDA, and 3-A Sanitary Standards:

- Stainless Steel 304 / 316L

The industry standard for sanitary equipment due to excellent corrosion resistance, weldability, and ease of cleaning. Ideal for piping, valves, and machine frames. - Aluminum Alloys (6061-T6)

Lightweight and corrosion-resistant, commonly used for non-contact structural components and automation frames. - Food-Grade Plastics (POM, UHMW-PE, PTFE, PEEK)

Provide excellent chemical resistance and low friction properties, suitable for gears, bushings, and contact surfaces. - Titanium Alloys (Grade 2 / Grade 5)

Used in specialized environments requiring ultra-high corrosion resistance and strength-to-weight ratios, such as dairy processing or acidic applications. - Brass/Bronze

Occasionally used in fittings and connectors due to antimicrobial properties, though increasingly replaced by stainless steel.

We also provide surface treatments including passivation, bead blasting, hard anodizing, and coating for added performance and compliance.

Our CNC Machining Capabilities for Food & Packaging Applications

Our facility is equipped to handle both prototype and volume production of precision parts for food and beverage machinery. Key capabilities include:

Machining Capabilities:

- 3-axis, 4-axis, and 5-axis CNC milling

- CNC turning with live tooling

- Swiss-type machining for small, intricate components

- Custom fixturing for sanitary part handling

- Surface finishing for hygienic compliance

Tolerances & Surface Quality:

- Dimensional tolerances: up to ±0.001mm

- Surface finish: as low as Ra 0.02μm (suitable for CIP/SIP systems)

- Form & position tolerance: within 0.002mm

Inspection & Quality Assurance:

- Zeiss CMM inspection and profile scanning

- Borescope checks for internal flow paths

- FDA/3-A material traceability certificates available

- ISO 9001:2015 certified facility

Hygienic design is at the core of our process—components are designed and inspected to eliminate crevices and ensure cleanability in accordance with industry best practices.

Typical CNC Machined Parts & Applications

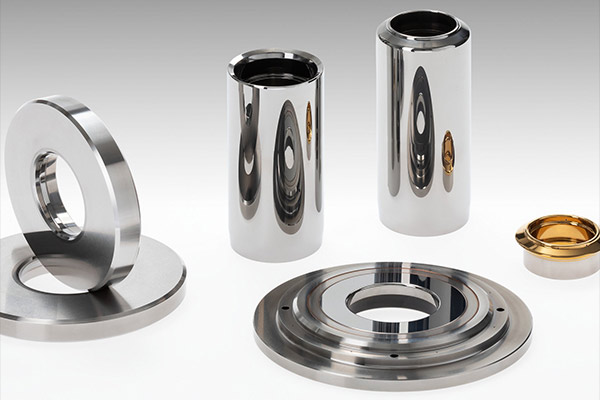

We manufacture a wide range of custom CNC components for equipment in food processing, beverage bottling, and automated packaging systems. Common parts include:

- Valve Bodies & Valve Stems – used in fluid dispensing systems, dairy separators, and automated CIP lines.

- Nozzles & Filler Heads – precision machined to ensure accurate liquid dosing without drips or contamination.

- Sealing Dies & Cutting Tools – for thermoforming and flow-wrap machines used in packaging baked goods, snacks, and meat products.

- Conveyor Bushings, Rollers & Guides – wear-resistant parts made from POM, UHMW, or stainless steel.

- Pump Housings & Impellers – corrosion-resistant components for sauce, beverage, or dairy circulation systems.

- Sensor Mounts & Brackets – precision-machined to maintain alignment of vision and weight-check systems.

All parts can be manufactured based on 2D drawings, 3D CAD models, or reverse-engineered from existing systems.

Project Example: Custom Stainless Steel Nozzles for High-Speed Bottling Line

A beverage producer needed custom 316L stainless steel filler nozzles for their high-speed carbonated bottling line. Requirements included a mirror-polished internal surface (Ra < 0.04μm), consistent inner bore diameter across all units, and leak-proof threading. We used 5-axis CNC machining, followed by electropolishing, and verified the flow path using non-contact optical metrology. The result: 99.98% fill accuracy across 50 million+ bottles per line annually—with zero corrosion failures after 18 months of operation.

Let’s Talk About Your Precision CNC Needs

When it comes to food, beverage, and packaging high-precision custom parts CNC machining, quality, hygiene, and durability are non-negotiable. Whether you’re upgrading legacy equipment or building next-gen automated lines, our team delivers the precision and dependability you need.

📩 Contact us now to discuss your project, request a custom quote, or upload your CAD files. We’re ready to support your innovation with precision CNC machining—designed for the demands of the food and packaging industry.