Precision CNC Machining Expert for Gears, Worms, Spline Shafts, and Transmission Components

High Precision is Essential in Power Transmission Applications

In the world of modern machinery—whether industrial automation, automotive systems, robotics, or aerospace—transmission components like gears, worm gears, spline shafts, and coupling elements play a vital role in ensuring accurate motion control, torque transfer, and mechanical efficiency. These components must operate under high load, high speed, and sometimes extreme environmental conditions. As such, the manufacturing tolerances, material strength, and surface finish of each part are critical to long-term performance.

As a trusted CNC machining expert in gears, worm gears, spline shafts, and precision transmission components, we specialize in producing highly engineered parts that meet the stringent requirements of global OEMs and system integrators.

Machining Challenges and Our Technical Solutions

Transmission components present unique manufacturing challenges due to their complexity, precision, and performance expectations:

- Tight tolerance control is essential for backlash-free engagement and silent operation.

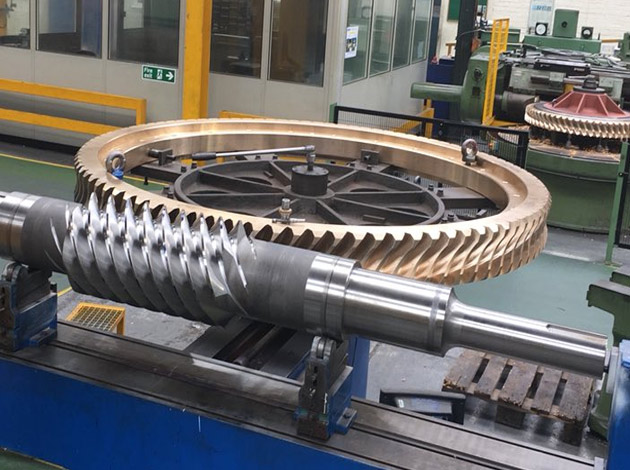

- Complex geometries such as helical splines or double-enveloping worm gears require multi-axis CNC machining and custom fixturing.

- Material hardness and heat treatment affect machinability and dimensional stability.

- Surface finish on gear teeth and splines must meet strict specifications for friction reduction and wear resistance.

- Axial and radial runout control is critical in high-speed rotational assemblies.

We address these challenges through:

- 5-axis CNC machining and multi-tasking turning-milling centers for one-pass complex part manufacturing;

- CNC gear hobbing and shaping with full parameter programming for involute, serration, and custom profiles;

- CNC grinding for tooth flanks, ID/OD, splines, and end faces to achieve high precision and ultra-low roughness;

- Automated deburring, shot blasting, and polishing to remove sharp edges and improve surface life;

- CMMs and gear measurement systems for 100% verification of profile, lead, pitch, and runout.

This full-process control enables us to meet the most demanding standards in automotive drivetrains, precision robotics, aerospace gearboxes, and more.

Commonly Used Materials and Their Characteristics

We work with a broad range of engineering metals and alloys tailored for mechanical strength, wear resistance, and machinability:

- Alloy Steels (e.g., 42CrMo4, 18CrNiMo7-6, SCM415): Widely used in gear and spline manufacturing for excellent strength, fatigue resistance, and compatibility with case hardening.

- Carbon Steels (e.g., C45, 1045, S45C): Economical and suitable for moderate-load transmission components.

- Stainless Steels (e.g., 17-4PH, 440C, SUS304): Used where corrosion resistance is required without sacrificing mechanical integrity.

- Aluminum Alloys (e.g., 7075, 6061-T6): Lightweight and used in aerospace and robotic transmission where weight is a factor.

- Bronze & Brass: Common in worm gear and bearing applications for their anti-friction and self-lubricating properties.

We also offer heat treatment services including carburizing, nitriding, induction hardening, and quenching, depending on material and application needs.

Advanced CNC Machining & Gear Manufacturing Capabilities

As a 齿轮、蜗杆蜗轮、花键轴、传动零件加工专家, our facility is fully equipped for both prototyping and volume production of complex transmission parts.

Precision Machining Capabilities:

- Gear Types Supported: Spur gears, helical gears, bevel gears, worm gears, planetary gears, timing pulleys

- Shaft Types: Spline shafts, keyed shafts, hollow shafts, multi-step drive shafts

- Tooth Forms: Involute, serrated, crowned, and custom profiles

- Tolerance: ±0.005 mm for standard features; ±0.001 mm for critical tolerances

- Surface Roughness: Down to Ra ≤ 0.2 μm for ground flanks or journal diameters

- Gear Quality: AGMA Class 11–12, DIN 6–7 achievable

Equipment Highlights:

- CNC gear hobbing/shaping machines (YCM, Liebherr, etc.)

- 5-axis CNC mills and turn-mill centers

- Gear flank grinders and spline grinders

- Zeiss CMM + gear profile measuring systems

- Shot peening and cryogenic treatment for fatigue life improvement

Typical Applications and Custom Parts We Manufacture

Our gear and transmission machining services support a wide range of industries:

- Automotive & EV: Differential gears, input/output shafts, electric motor drive splines

- Robotics: Compact gear sets, worm reducers, harmonic drive housings

- Industrial Machinery: Power transmission shafts, timing pulleys, gearbox internals

- Aerospace: Lightweight yet high-strength transmission modules

- Marine & Agriculture: Helical gears and spline connections for power take-offs and transfer cases

Each part is custom-produced based on your technical drawings, performance specifications, and tolerance stack-up needs. Reverse engineering and 3D model validation are also available.

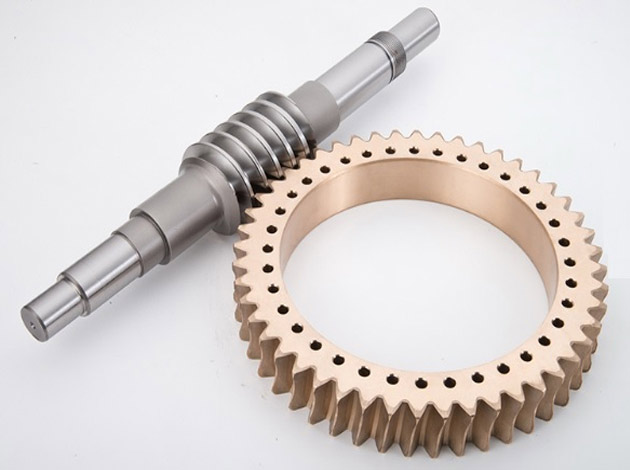

Case Study: Custom Worm Gear Pair for Precision Indexing Table

We recently supplied a set of precision worm gear and worm shaft components used in a robotic indexing system:

- Material: Worm – 40Cr (hardened & tempered); Gear – Tin Bronze ZQSn10-1

- Accuracy: Gear pitch error ≤ ±0.005 mm; backlash ≤ 0.02 mm

- Surface Finish: Ra ≤ 0.4 µm on worm threads

- Inspection: Gear tester + CMM + full material traceability

The system achieved <0.01° indexing accuracy and extended operating life by 3× versus previous suppliers’ designs.

Work With a Transmission Parts CNC Machining Expert

If you’re looking for a manufacturing partner who understands the critical requirements of precision gear and transmission machining, we’re here to support you with advanced equipment, experienced engineers, and robust quality systems.

As a Gear, Worm, Spline Shaft, Transmission Parts Machining Specialist, we combine deep industry knowledge with modern CNC technologies to deliver performance-driven components tailored to your needs.

👉 Request a Quote Today — Precision Transmission Parts, CNC-Machined for Performance and Reliability.