Precision CNC Machining for Advanced Coupling & Torque Control Components

Mastering Torque, Precision, and Motion — Where Function Meets Accuracy

Power transmission is more than just spinning parts — it’s the controlled, intelligent flow of torque across complex systems. Whether it’s a dual-mass flywheel, a magnetic clutch carrier, a torque limiter, or a high-speed coupling, the smallest deviation can result in misalignment, noise, vibration, or catastrophic failure.

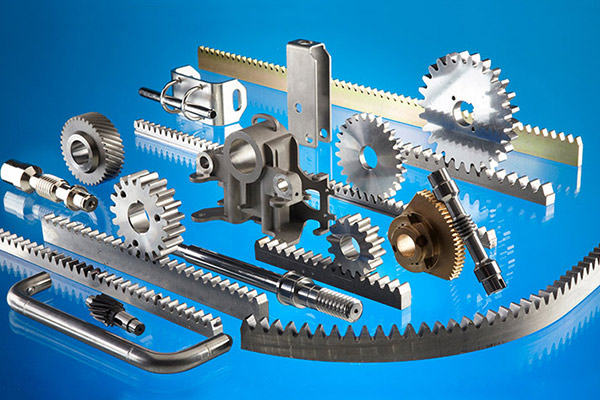

We offer precision machining solutions for complex torque control components, including clutch hubs, differential housings, custom couplings, torque limiters, and overload release structures. Our experience covers everything from off-road trucks to robotic arms, EV platforms to wind turbine yaw drives.

✔ Key Challenges in Clutch & Coupling Component Machining

These parts face extreme mechanical and thermal loads, and require multi-process integration:

- Multi-step precision: Clutch hubs and differential housings involve turning, gear cutting, broaching, heat treatment, and post-grind—all in tightly stacked tolerances.

- Internal spline accuracy: Misaligned spline teeth cause premature wear and NVH issues.

- Dynamic stress resistance: Rotating couplings and torque limiters must withstand overload cycles without deformation.

- Coaxiality + flatness across assemblies: Essential in multi-disc clutch packs or flywheel mating structures.

- Thermal distortion: High-power couplings and flywheels often require material-specific compensation during machining.

✔ Parts We Specialize In

| Component | Application | Precision Focus |

|---|---|---|

| Clutch Hubs & Plates | Automotive / heavy-duty / EV | Flatness < 0.01mm, spline DIN 9 |

| Dual-Mass Flywheel Carriers | ICE + hybrid vehicles | Balance grade G2.5, profile tolerance ±0.02mm |

| Torque Limiters & Overload Units | Industrial gearboxes, wind turbines | Material integrity + stress dispersion machining |

| Custom Couplings (flexible, diaphragm, jaw) | Automation / robotics / CNC | Positional and angular accuracy within ±0.01° |

| Differential & Planet Carriers | Off-road & defense vehicles | Multi-process concentricity control |

| Slotted & Interference Components | Hydraulic + electro-mechanical drives | Wire EDM + high-torque interference fits |

✔ Materials & Treatments We Commonly Use

| Material | Treatment | Benefit |

|---|---|---|

| 8620 / 20CrMnTi / SCM420 | Carburized, ground | Ideal for hardened gear hubs & splines |

| S50C / 1045 / C45 Steel | Induction hardening | Cost-effective for medium-load clutch parts |

| Alloy Tool Steels (SKD11, D2) | Vacuum tempering | Superior fatigue resistance for overload elements |

| Stainless Steel (17-4PH, SUS420J2) | H900 hardening / polishing | Corrosion + wear resistance for marine/EV couplings |

| High-Modulus Composites (on request) | Dry machining / precision boring | For lightweight flex couplings or torque sensors |

Surface finishing includes: black oxide, manganese phosphate (anti-friction), electroless nickel plating, fine polishing (Ra ≤ 0.2μm), and grinding to <0.005mm tolerances.

✔ Our Manufacturing Capabilities

We offer full-stack production with the following key equipment and processes:

- 5-axis CNC milling for asymmetric coupling features

- Multi-axis turning centers for stepped hubs and spline sleeves

- Internal & external spline cutting (DIN/AGMA) with in-house broaching & hobbing

- Form grinding and profile matching for engagement surfaces

- High-speed balancing (up to 30,000 rpm)

- Laser marking, assembly fit simulation, and leak testing where required

Quality Inspection Highlights:

- CMM inspection for datum structure verification

- Zeiss gear testers for internal/external spline control

- Ultrasonic testing for critical clutch or carrier forgings

- Torque resistance testing (optional) for coupling validation

✔ Global Experience Highlights

- ✅ Overload clutch hubs for German industrial reducer brand (carburized, DIN 8)

- ✅ Dual-mass flywheel carriers (Ra 0.4μm) for a Korean hybrid vehicle platform

- ✅ Jaw couplings (μm-level bore tolerance) for Japanese robotic automation firm

- ✅ Differential sleeves and shafts for U.S. off-road heavy equipment builder

✔ Why Choose Our Machining for Torque-Critical Assemblies?

- 🔧 Deep understanding of dynamic torque loads and fatigue control

- 🌀 Integrated balancing, spline forming, and post-hardening grinding

- 📈 Capability for PPAP, SPC, and 100% inspection for safety-critical applications

- 🌎 Serving international markets in automotive, automation, defense, wind energy

- ⏱ Samples in 7–12 days, with full DFM support and quality reports

🧩 Power Is Nothing Without Precision — Machining That Connects the Motion

From flexible couplings in robots to heavy-duty clutch packs in off-highway vehicles, we build every component to exacting standards — so your systems stay strong, synchronized, and safe under real-world loads.

📩 Contact us now to discuss your custom coupling or torque solution project.