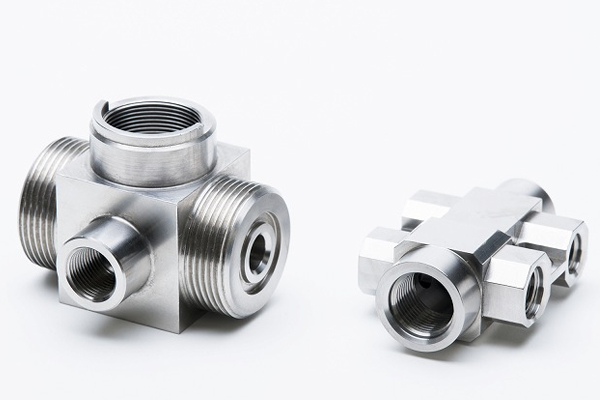

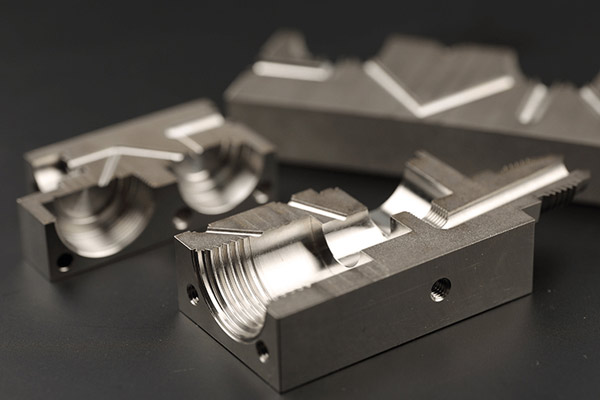

Precision CNC Machining for Chemical Delivery & Fluid Control Components

Specializing in Ultra-Pure, Corrosion-Resistant Flow System Parts for Semiconductor Applications

In the front-end of semiconductor manufacturing, ultrapure chemical and gas delivery systems are critical to ensure yield, device reliability, and process repeatability. Every valve body, fitting, housing, and microfluidic connector must be machined with high chemical resistance, leak-proof integrity, and particle-free internal surfaces.

With over 20 years of experience, our factory in China provides precision machining solutions for chemical fluid system components used in wet benches, CMP tools, cleaning stations, and gas cabinets for semiconductor fabs worldwide.

✔ Key Manufacturing Challenges in Semiconductor Fluid Control Parts

Machining parts for ultrapure chemical delivery systems demands exceptional attention to:

- Chemical compatibility: Components are exposed to acids, solvents, and oxidizers like HF, H₂SO₄, NH₄OH, and H₂O₂.

- Particle-free surfaces: Any microburrs, scratches, or machining residues can contaminate wafer surfaces.

- Sealing reliability: Tolerances on sealing surfaces often require ±0.005mm or better to ensure vacuum/gas tightness.

- Precision flow control: Internal geometries affect flowrate and turbulence, so surface smoothness and dimensional accuracy are key.

✔ Material Expertise: High Purity Meets High Precision

We specialize in machining the following materials for fluid control components:

| Material | Application | Processing Notes |

|---|---|---|

| PFA (Perfluoroalkoxy) | Valve bodies, tubing connectors | High-speed milling, anti-slip fixturing, low-stress machining |

| PTFE (Teflon) | Diaphragms, seals, liners | Ultra-slow tool paths to prevent cracking, precision deburring |

| PEEK | Pump parts, chip holders | CNC with internal cooling, chamfering to eliminate stress points |

| PVDF / PPS | Flow meters, fittings | CNC turning + laser marking for traceability |

| SUS316L (electropolished) | Gas manifolds, high-pressure housings | Internal Ra ≤ 0.2μm by polishing + passivation |

| Aluminum (anodized or PTFE-coated) | Pump chassis, interface frames | Type III hard anodizing or fluoropolymer coating |

All materials are sourced from industry-compliant suppliers and conform to SEMI F57, RoHS, and REACH standards.

✔ Manufacturing Capabilities & Quality Assurance

To guarantee the required purity and functionality of fluid components, we offer:

- Multi-axis CNC machining – For PFA/PTFE/PEEK with burr-free precision

- Mirror-finish boring & honing – For valve seats and flow paths (Ra < 0.1μm)

- CNC turning for polymer fittings – With fine internal threading and chamfers

- Vacuum leak testing (helium or air-based) – For valve housings and chambers

- Ultrasonic cleaning – In DI water + Class 1000 packaging to prevent particle contamination

Inspection tools include:

- Zeiss CMM with polymer-compatible probing

- Internal diameter gauges calibrated for soft materials

- Roughness meters for polymer and metal surfaces

- Full COA, MSDS, and traceable batch control

✔ Global Projects Delivered

- ✅ Custom PTFE valve bodies for a Japanese wet process equipment supplier

- ✅ PEEK flow restrictors delivered to an American CMP tool integrator

- ✅ SUS316L precision manifolds for a German ultrapure gas cabinet maker

- ✅ PFA fittings and union joints supplied to cleanroom facilities in Israel, Singapore, and Taiwan

We also support quick-turn prototyping with specialty polymers and provide co-engineering assistance to adapt parts for easier sealing, installation, or automation integration.

✔ Why Top-Tier Semiconductor Facilities Choose Us

- ✅ Over 20 years focused on precision fluidic component manufacturing

- ✅ Expertise in both high-purity polymers and electropolished metals

- ✅ Tolerances down to ±0.005mm on sealing and flow surfaces

- ✅ Full cleanroom compliance with Class 1000 inspection and packaging

- ✅ Exported to 30+ countries with traceable batches and fast lead times

💧 Let’s Build Cleaner, Safer Flow Systems Together

Whether you’re designing a next-gen wet bench, CMP system, or chemical pump, we can deliver ultra-precise, reliable parts tailored to your application — with full traceability and global logistics support.

📩 Share your drawings and specifications today to get a quote within 24 hours.