Precision CNC Machining for Construction Machinery & Automation Components

In the field of construction machinery and industrial automation, the demand for precision-machined components is steadily rising, driven by the push for higher load capacity, increased automation, and smart system integration. Parts such as hydraulic motor housings, gearbox casings, robotic arm joints, actuator pistons, and cam followers require exceptional dimensional stability and durability under extreme working conditions.

Key Machining Challenges:

These components typically involve complex geometries, tight tolerances (often within ±0.005mm), and difficult-to-machine materials like high-strength alloy steels, hardened tool steel, or wear-resistant coatings. Vibration, high heat generation, and tool wear must be carefully mitigated during machining to avoid micro-cracks or dimensional distortions—especially in thin-walled or high-aspect-ratio parts.

Material Application & Optimization:

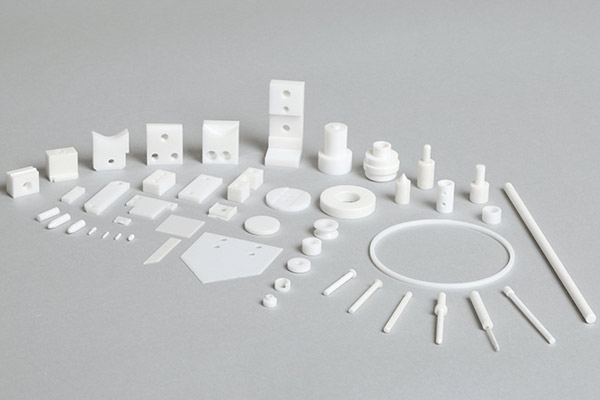

High-performance materials such as 42CrMo, SCM440, AISI 4340, and nitrided steel are commonly used for their fatigue strength and wear resistance. For automation parts, lightweight aluminum alloys (6061, 7075) and engineering plastics (PEEK, Delrin) are integrated to reduce inertia and improve responsiveness. Our engineers leverage heat treatment and surface hardening processes (like carburizing or nitriding) to extend part life and performance consistency.

Process Control Excellence:

Our CNC plant, with over 20 years of experience, ensures consistent quality through fully integrated process control:

- 5-axis simultaneous machining for complex contours and multi-surface parts.

- In-process probing and real-time compensation for thermal drift.

- Coordinate Measuring Machines (CMMs) and circularity testers ensure geometric tolerances meet strict international standards.

- Grinding & honing processes further refine mating surfaces for optimal fit and seal.

Equipment Utilized:

- Mazak Integrex and DMG Mori NT series for multi-tasking turn-mill operations.

- Studer S33 cylindrical grinders for high-precision shaft finishing.

- Zeiss Contura CMM, Mitutoyo roundness testers, and Tokyo Seimitsu form testers for quality assurance.

- Wire EDM and EDM sinkers for internal cavities and fine features in automation parts.

Global Applications:

We have manufactured gearbox shafts, cylinder sleeves, and rotary actuators for clients in Germany’s construction equipment sector, servo motor end caps and robotic couplings for American automation integrators, and precision hydraulic parts for Japanese heavy machinery OEMs. Our commitment to ±0.001mm tolerance capability and batch consistency has earned long-term partnerships in more than 20 countries.