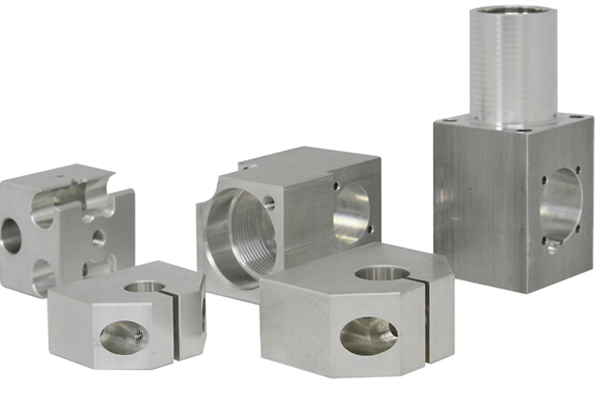

Precision CNC Machining for Construction Machinery & Industrial Automation Components

With over two decades of experience in high-precision CNC machining, our factory delivers ultra-reliable, custom-machined components for construction machinery and industrial automation systems worldwide. These sectors demand robust, high-precision parts that can endure extreme mechanical stress, fluctuating temperatures, and continuous operation—all while maintaining tight tolerances and consistent performance.

⚙️ Machining Challenges in the Industry

- Large-Scale Structural Complexity

Components like slewing bearings, drive shafts, and hydraulic cylinder housings often exceed 1 meter in size, with complex geometries and deep internal cavities. Achieving ±0.01mm tolerance on large parts requires advanced multi-axis machining and thermal compensation strategies. - High-Stress Surface Integrity

Gears, couplings, and automated drive parts must resist cyclic loading, vibration, and wear. This requires both high-hardness materials and flawless surface finishes (Ra ≤ 0.4 μm), especially on bearing or sealing surfaces. - Functional Integration

Automation components often combine mechanical, hydraulic, and electronic interfaces, requiring precise multi-step machining and tight perpendicularity/parallelism control (≤0.005mm) across multiple faces.

🧱 Material Solutions for Durability & Performance

- High-Tensile Alloy Steels (e.g. 42CrMo4, AISI 4140)

Used in shafts, pins, and drive parts for high fatigue resistance and hardenability via quenching and tempering. - Heat-Resistant Stainless Steel (e.g. SUS630, 17-4PH)

Applied in automation end effectors or sensor housings where corrosion resistance and strength are both critical. - Aluminum Alloys (7075-T6, 6061-T6)

Lightweight and thermally conductive for servo actuator brackets and robotic arms, often hard anodized post-machining. - Bronze & POM (Engineering Plastics)

Used for wear-resistant bushings or linear guide interfaces in automated assemblies.

🛠️ Key Process Control & Manufacturing Technologies

- 5-Axis Machining Centers (Makino, DMG MORI)

Capable of complex multi-face machining and continuous contouring for intricate automation components. - Double Column CNC Gantry Mills

Ensures flatness and parallelism over large castings or base plates, critical for machine tool foundations. - Precision Cylindrical & Surface Grinding (STUDER, Okamoto)

Achieves micron-level roundness and surface finish on shafts, rollers, and cam followers. - In-House Heat Treatment

Controlled quenching and tempering to reach hardness ranges (HRC 38–45) while maintaining dimensional stability. - 100% Inspection via Zeiss CMM & Roundness Tester

Guaranteeing form and position tolerances down to 0.002mm and 3D inspection reports for each shipment.

🌍 Global Case Studies

- Germany – Robotic Welding Line Component Supplier

Delivered ±0.005mm tolerance end effectors and tooling arms machined from anodized 7075-T6 aluminum, enabling 20% faster cycle time in automotive welding lines. - USA – Earthmoving Equipment OEM

Supplied hardened 42CrMo4 swing bearings and pin bores with Ra0.2μm finish, improving fatigue life by over 40% in harsh mining environments. - Japan – Factory Automation Integrator

Manufactured precision gear housings and spindle supports with tight coaxiality requirements (<0.01mm) for high-speed pick-and-place systems.