Precision CNC Machining for the Optical Industry: Mastering Nanometer-Level Accuracy

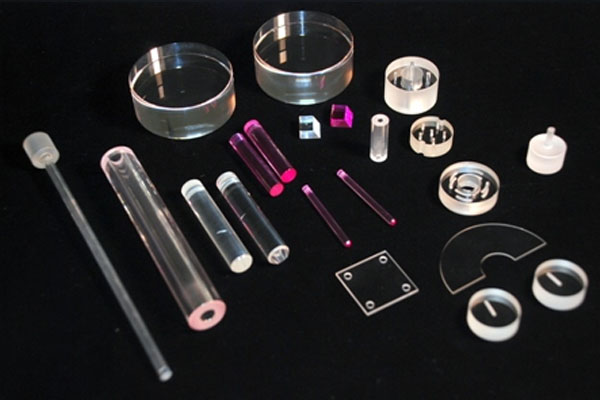

The optical industry demands the highest levels of precision and surface integrity, especially for components such as lens holders, optical brackets, laser housings, adjustment rings, and mirror mounts. The slightest deviation can impact light transmission, alignment, and imaging performance. This is where our 20+ years of high-end CNC machining expertise becomes critical.

Machining Challenges:

- Surface Finish Control: Optical components often require surface roughness below Ra 0.05μm, especially on mating or reflective surfaces.

- Dimensional Tolerance: Complex parts demand tolerances within ±0.002mm or even sub-micron accuracy to ensure precise optical alignment.

- Material Fragility: Many optical parts are made from soft metals like aluminum, brass, or brittle ceramics, making deformation and micro-cracks a common concern during high-speed machining.

- Thermal Stability: Even the slightest heat-induced deformation can shift the optical axis or focal length, thus machining must be done with extremely stable thermal management.

Material Engineering:

We work with a wide range of materials used in optical applications, including:

- Aluminum 6061-T6/7075: Lightweight and stable, ideal for optical mounts.

- Stainless Steel (303/316/17-4PH): Used in precision optics for high strength and corrosion resistance.

- Titanium Alloys: Lightweight and non-magnetic, often used in aerospace-grade optical systems.

- Technical Ceramics & Sapphire: For ultra-hard, transparent, and thermally stable parts; these are machined using diamond tools and fine grinding technologies.

- PEEK & PTFE: For non-metallic, ultra-clean optical components.

Process & Quality Control:

- Machining Strategy: Our process includes 5-axis simultaneous milling for complex geometries, mirror-finishing via diamond turning, and thermal deformation simulation prior to programming.

- Precision Equipment:

- Mikron HSM 500U/700U: High-speed 5-axis milling for mirror-grade surfaces.

- Moore Nanotech Diamond Turning Machines: Achieving <50nm form accuracy for critical optical components.

- Zeiss CMM & White Light Interferometers: For 3D surface metrology and sub-micron inspection.

- Cleanroom Assembly Readiness: We offer particle-free packaging and optional cleanroom pre-assembly services.

Global Case Studies:

- Germany – High-Resolution Laser Scanner Housing: CNC-milled from 7075-T6 with internal baffles and alignment features, all machined in a single clamping to ensure optical path integrity.

- USA – Astronomical Telescope Brackets: Titanium components for vibration-free performance in harsh environments.

- Japan – Precision Mirror Adjustment Mounts: Delivered with parallelism <2μm and anodized for anti-reflection treatment.

Why Choose Us:

With over two decades of experience, we’ve built an international reputation for precision, consistency, and problem-solving in high-spec optical manufacturing. Whether for aerospace optics, scientific instrumentation, or industrial laser systems, we ensure each part meets the most demanding optical standards — every micron matters.