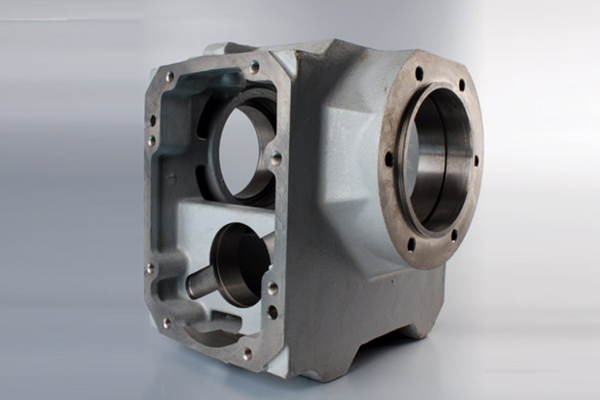

Precision Machining for Construction Machinery & Industrial Automation Components

With over 20 years of experience in high-precision CNC machining, our factory delivers advanced solutions for critical components used in construction equipment and industrial automation systems. We specialize in producing customized mechanical parts that demand micron-level tolerances, superior wear resistance, and long-term structural reliability under harsh operating conditions.

Machining Challenges in the Industry

Construction and automation sectors require components that can withstand continuous high-load motion, abrasive environments, and complex kinematic interactions. The key challenges include:

- Achieving ±0.001 mm tolerances on components exceeding 500 mm in length.

- Maintaining concentricity and coaxiality on shafts and cylinder bores under 0.002 mm.

- Processing complex 5-axis contours for robotic joint mechanisms and actuator housings.

- Surface finish control below Ra0.2 μm for sliding or sealing interfaces.

Material Utilization for Superior Performance

To meet the industry’s mechanical and environmental demands, we work with a broad range of high-performance materials:

- 42CrMo, 34CrNiMo6: Used for high-strength transmission shafts and couplings.

- QT600 and forged steel: Applied to heavy-duty bracket systems and structural joints.

- Stainless steel (304, 316L): For corrosion-prone automation parts and hydraulic manifolds.

- PEEK and PTFE composites: For wear-resistant automation sliders, bushings, and insulators.

We use vacuum heat treatment, nitriding, and cryogenic stabilization to enhance material performance, hardness, and dimensional stability.

Process Control & Equipment Integration

Our precision is ensured by a highly integrated process flow:

- Rough machining on Mazak and Doosan turning centers.

- Milling and contouring on Mikron and DMG MORI 5-axis machining centers.

- Grinding using Studer cylindrical grinders with automatic balancing.

- Deep-hole drilling and honing for hydraulic and pneumatic components.

Quality assurance is embedded in every step with in-house measurement tools:

- ZEISS CMMs with scanning probes.

- Mitutoyo roundness testers for shaft and bore integrity.

- Hommel surface profilometers to monitor surface roughness.

Global Case Studies

- Germany: Delivered hydraulic cylinder heads and control blocks for a top-tier excavator brand; all units passed EN ISO 6020-2 fatigue testing.

- USA: Developed precision linear rail supports for a warehouse automation integrator; met ISO 2768-mK standards and delivered with PPAP documentation.

- South Korea: Supplied robotic joint flanges and worm gears to a Tier-1 automation robotics firm; components maintained <2 μm positional tolerance over 10,000 cycles.