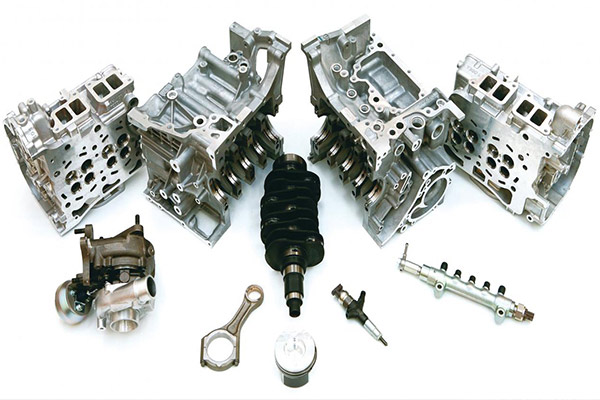

Precision Machining for Powertrain & Engine System Components

Delivering Micron-Level Accuracy for the Heart of Motion

Powertrain and engine components lie at the very core of modern mobility — whether in internal combustion engines, electric drives, or hybrid systems. These parts must withstand high loads, rapid thermal cycling, friction, and vibration, all while operating within micron-level tolerances. Failure is not an option.

With 20+ years of experience, our precision CNC machining facility in China provides high-performance powertrain components for global OEMs and Tier-1 suppliers across automotive, aerospace, and industrial machinery.

✔ Challenges in Machining Powertrain & Engine Parts

The combination of high mechanical stress, tight tolerances, and mass production consistency makes this one of the most demanding sectors in precision manufacturing:

- Complex geometries: Crankcases, gear housings, and cylinder heads require multi-axis milling, deep cavity access, and sealing surface integrity.

- Dimensional stability: Shafts, rotors, and sleeves must hold roundness, coaxiality, and tolerance stack-ups under dynamic conditions.

- Heat-affected zones (HAZ): For components that undergo hardening or welding, thermal deformation must be compensated in design and process.

- Friction-sensitive mating: Components like piston pins, valve guides, and cams demand ultra-low Ra and hardened surfaces.

- Production volume repeatability: Long-term tooling wear, SPC tracking, and real-time process control are essential for automotive-scale production.

✔ Materials We Excel At for Engine & Transmission Parts

| Material | Application | Notes |

|---|---|---|

| Alloy Steel (4140, 8620, 20CrMnTi) | Gears, shafts, axles | Quenching + tempering + grinding to HRC 58+ |

| Ductile Iron / Grey Cast Iron | Cylinder blocks, housings | Vibration-damped boring + honing + leak testing |

| Aluminum Alloys (ADC12, A356-T6, 6061-T6) | Engine covers, EV gearboxes | Cast & billet types, CNC + precision reaming |

| Tool Steel (SKD11, H13) | Punches, dies, inserts | Vacuum heat treat + wire EDM finish |

| Brass / Bronze | Bushings, synchronizer rings | CNC turning + broaching + surface coating |

| Stainless Steel (SUS304, 17-4PH) | High-temp engine sensors, turbo housings | Corrosion/heat resistant + TIG welding optional |

✔ Our Manufacturing Capabilities for Motion-Critical Components

We operate a full line of CNC and supporting technologies purpose-built for transmission and engine parts:

- 4/5-Axis Horizontal Machining Centers (Makino, OKK) – For gear housings, crankcases, and cover plates

- Multi-Spindle CNC Lathes – For shaft, sleeve, and journal-type parts with concentricity control

- CNC Gear Hobbing & Spline Cutting – In-house gear tooth machining and DIN class inspection

- Surface & OD Grinding – Cylindricity to <0.003mm and surface Ra < 0.2μm for contact surfaces

- Ultrasonic Cleaning & Magnetic Particle Inspection (MPI) – For fatigue-critical engine parts

QC Equipment Includes:

- Zeiss CMM with 3-axis scanning

- Roundness tester (Taylor Hobson)

- Gear measuring center (Klingelnberg P26)

- Surface profiler, tensile tester, hardness tester

- 100% functional and pressure leak testing (for housings)

✔ Global Projects We’ve Delivered

- ✅ Aluminum EV gearbox housings for German Tier-1 supplier (flatness <0.01mm, oil channel integrity tested)

- ✅ Induction-hardened spline shafts for US-based off-highway engine builder

- ✅ Valve plate bushings and pump rotors for Japanese construction machinery brand

- ✅ Cast iron cylinder sleeves machined and honed for Brazilian diesel engine OEM

✔ Why Top Motion System Integrators Work With Us

- 🏭 20+ years of CNC experience with drivetrain-grade tolerances

- ⚙️ Vertical integration of heat treatment, surface grinding, and gear cutting

- 📊 ISO/TS16949 quality management + full PPAP/FAIR documentation available

- 🚛 Global delivery with export clients in Germany, Japan, USA, Brazil, and India

- ⏱ Fast sampling turnaround — 7~15 days for most custom powertrain parts

⚙️ Built for Torque, Tuned for Precision

Whether you’re producing next-generation EV gearboxes, ICE engine heads, or high-speed rotating shafts, we deliver CNC solutions that hold up to speed, heat, and pressure — for millions of cycles.

📩 Send your drawing today — we’ll respond within 24 hours with DFM feedback and a fast quotation.