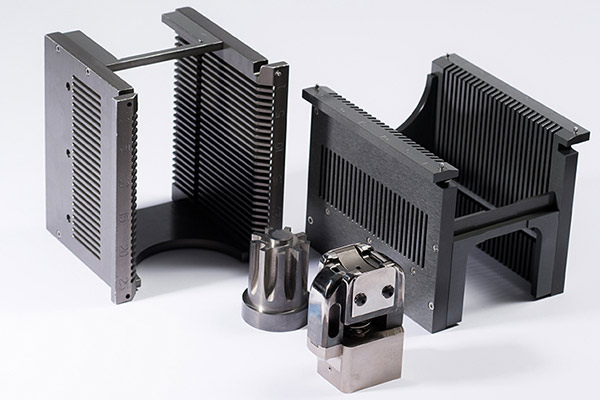

Precision Machining for Semiconductor Inspection & Metrology Equipment Components

Where Nanometer-Level Stability Starts with Micron-Level Machining

In modern semiconductor fabs, inspection and metrology equipment ensures every wafer meets atomic-scale accuracy. From CD-SEM to optical profilers and defect review systems, the structural and mechanical components of these machines must deliver zero vibration, extreme flatness, and dimensional repeatability — often under vacuum or anti-vibration isolation platforms.

For over 20 years, our CNC factory in China has served global semiconductor inspection tool manufacturers with precision frames, optical mounts, stage assemblies, and low-deformation structures — machined and measured down to micron tolerances.

✔ What Makes Inspection Equipment Components So Challenging?

These parts demand not just precision — but consistency and purity:

- Ultra-flat surfaces: Bases and stages often require flatness < 0.005mm across >500mm dimensions.

- No vibration / deformation: Frame structures must maintain geometric integrity under load, thermal drift, or vacuum.

- Material damping & stability: Specific alloys or granite-hybrid parts are used to suppress motion or vibration.

- Cleanroom-grade finish: Surfaces must be burr-free, particle-free, and contamination-free for Class 10/100 environments.

- Precision assembly tolerance: Multiple parts must align in micron-accurate positioning (optics, sensor beds, X/Y stages).

✔ Materials We Work With — For Opto-Mechanical Perfection

| Material | Typical Application | Machining Highlights |

|---|---|---|

| Tooling-grade Aluminum (MIC6, 6061-T6) | Base plates, frame structures | Stress-relieved + precision milling, flatness < 0.01mm |

| Granite (with inserts) | Optical stage beds | Surface grinding + steel thread inserts + lapping |

| Cast Iron & Polymer Concrete | Damping bases, heavy metrology platforms | Low-vibration, epoxy-fill machining + dynamic balancing |

| Titanium / Invar | Thermal-invariant structures | 5-axis control + heat compensation machining |

| SUS304 / 316 | Vacuum enclosures, optics frames | CNC + electropolish + vacuum testing |

✔ Advanced CNC Capabilities for Nanometer-Critical Parts

Our factory operates equipment specifically calibrated for ultra-flat, low-deformation parts:

- CNC Gantry Milling (1.5m travel) – Ideal for large aluminum optical plates and machine frames

- Double-sided Surface Grinding – Ensures parallelism and flatness < 0.005mm

- Coordinate Jig Boring – For ultra-precise hole-to-hole repeatability in assemblies

- Vibration Dampening Inserts & Balancing – For cast bases, platforms, and isolation frames

- Clean Assembly Room – For subassembly-level delivery (mechanical + optical mounts)

Metrology Equipment Includes:

- Zeiss CMM with scanning probe for <±1μm 3D verification

- Surface flatness laser interferometry (up to 1000mm)

- Roundness/cylindricity gauge (Mitutoyo RA-2200)

- High-magnification vision inspection for edge & thread quality

✔ Delivered Projects for Global Inspection & Metrology Integrators

- ✅ MIC6 optical base plates (Ra < 0.2μm, flatness < 0.01mm) for a German wafer inspection OEM

- ✅ Granite stage assemblies with embedded alignment holes for a Japanese metrology group

- ✅ Titanium sensor brackets for an Israeli CD-SEM equipment builder

- ✅ SUS316L vacuum chambers for defect review systems exported to the USA

We support both build-to-print and co-design partnerships, helping customers optimize from prototype to series production.

✔ Why Semiconductor Metrology Brands Choose Our CNC Services

- 🏭 Over 20 years focused on ultra-precision machining

- 🎯 Expertise in flatness-critical, motion-critical, and vacuum-grade assemblies

- 🧼 Cleanroom-compliant finishes, ultrasonic cleaning, and Class 1000 packaging

- 🌍 Exported to over 30 countries across Asia, Europe, and North America

- ⚙️ Engineering support from concept to final inspection

📐 Let’s Help You Measure the Future — One Micron at a Time

Whether you’re building an overlay metrology platform, a vacuum inspection chamber, or a next-gen optics bed — we bring the machining precision that enables your measurement precision.

📧 Send your drawings today and receive a technical consultation within 24 hours.