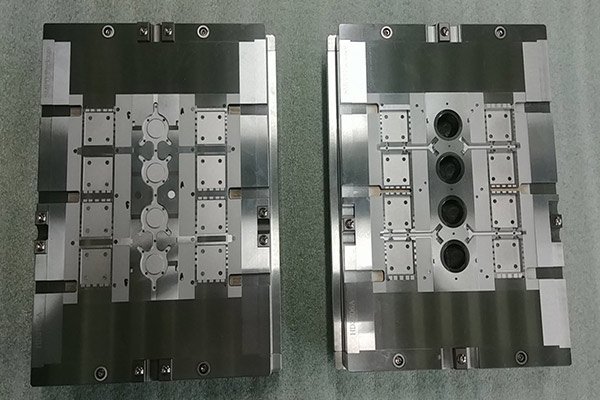

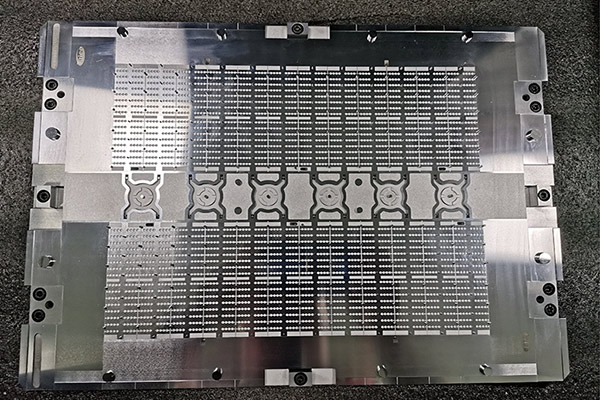

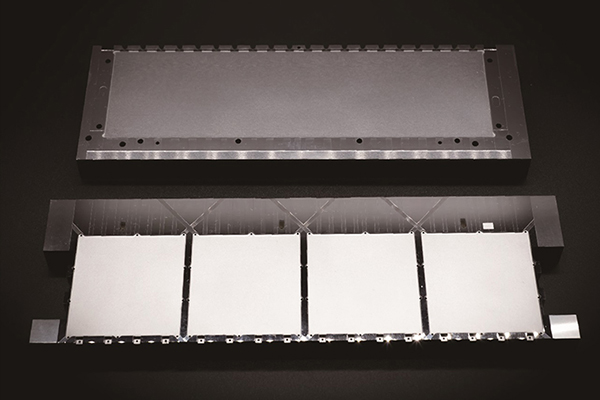

Precision Machining for Semiconductor Packaging & Final Test Components

Enabling Reliable IC Testing and High-Yield Packaging with Sub-Micron CNC Expertise

At the final stage of semiconductor manufacturing, precision means everything. Whether it’s in probe cards testing 5nm chips, sockets exposing micro-pins to mechanical stress, or packages requiring perfect co-planarity — component integrity directly affects yield, signal integrity, and device lifetime.

With over two decades of CNC manufacturing experience, our China-based facility provides ultra-precise, cleanroom-ready components for leading packaging houses, test handlers, probe card manufacturers, and OSATs globally.

✔ Machining Difficulties in Packaging & Test Hardware

Packaging and test parts may look small — but their complexity and tolerance requirements are world-class:

- Micro-hole & micro-slot machining: Probe card plates often require holes <0.2mm with ±0.005mm positional accuracy.

- Ultra-thin walls & micro features: High-density test sockets and stiffeners demand 0.2mm or thinner walls without deformation.

- High thermal & electrical performance: Materials must remain dimensionally stable under high temperature and cycling loads.

- Planarity & parallelism: Contact areas must maintain <0.01mm flatness across entire surfaces to ensure test signal reliability.

- Non-magnetic, ESD-safe, and low-particle surfaces: Especially critical in advanced node testing and Class 100 cleanrooms.

✔ Materials We Master for High-Precision Test & Packaging Parts

| Material | Common Use | Machining Focus |

|---|---|---|

| Ceramics (Alumina / Zirconia / Silicon Nitride) | Probe card stiffeners, contact blocks | Diamond tooling, non-chipping edge profiling |

| Super Engineering Plastics (PEEK, Torlon, Ultem) | Test sockets, inserts, isolation fixtures | Burr-free micro-drilling and ultra-clean chamfering |

| Tool Steel (SKD11, M2) | High-wear pins, jigs | Heat treated to HRC 60+, ground to <0.002mm tolerance |

| Beryllium Copper (BeCu) | Micro-spring holders, socket frames | Special alloy handling with surface passivation |

| Titanium Alloys | Probe card carriers | Ultra-lightweight and low thermal expansion |

| C1100 / OFHC Copper | Heat spreaders | CNC + polishing + Ni/Au plating for thermal/electrical performance |

All materials are traceable and RoHS/REACH compliant, with options for Ni plating, Au coating, black oxide, or PEEK overmolding.

✔ CNC & Finishing Capabilities Tailored for IC Test & Packaging

Our workshop integrates specialized processes to meet the micro-mechanical requirements of the test world:

- Micro-hole CNC Drilling (≤φ0.1mm) – With ±0.005mm positional tolerance

- EDM + Wire-Cut for Tool Steel & Titanium – For ultra-fine slots, edge profiling, sharp corners

- Mirror Surface CNC Milling & Lapping – Flatness < 0.005mm and Ra ≤ 0.1μm

- Diamond Grinding for Ceramics – Crack-free edge shaping and high-precision ID/OD grinding

- Assembly-Ready Finishing – Anodizing, electroless Ni/Au, and cleanroom packaging

Inspection Equipment Includes:

- Nikon Vision System for micro-feature inspection

- CMM + height gauge for planarity and parallelism

- X-ray coating thickness measurement (for plated layers)

- Surface profiler for burrs and Ra < 0.05μm

✔ Global Cases – We Build for the Final Step That Matters Most

- ✅ Precision ceramic probe card plates for a Japanese ATE system integrator

- ✅ PEEK ultra-thin IC socket frames for a U.S. OSAT company

- ✅ Beryllium copper contact modules for a Taiwan-based wafer-level test group

- ✅ Mirror-polished heat spreaders for advanced packaging in Singapore & Malaysia

We support rapid prototyping (under 7 days), small-volume pre-launch runs, and high-mix production for custom IC packages.

✔ Why Global Packaging & Test Leaders Work with Us

- 🏭 20+ Years of CNC experience with fine-feature, thin-wall, and hybrid material machining

- 📐 Micro-hole accuracy, ultra-flat surfaces, and full burr control

- 🧼 Cleanroom-ready finishing & packaging (Class 1000)

- 🔩 Support for assembled modules (e.g., ceramic + metal + polymer stacking)

- 🌍 Global delivery to fabs, OSATs, ATE and test socket manufacturers in 30+ countries

🧪 Let’s Make Your Final Stage Perfect — Contact-Ready, Burr-Free, Precision-Cut

Precision packaging and test components don’t just hold chips — they hold your yield rate, reliability, and reputation. Partner with us for CNC excellence you can measure in microns and trust in mass production.

📤 Upload your drawing today — receive a quote and DFM review within 24 hours.