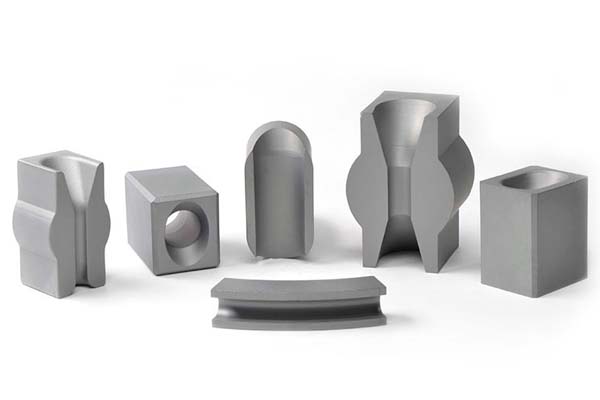

Precision Machining for Steel Production & Wire Forming Equipment

Machined to Endure — High-Durability Components for the Heart of Steel

In the heavy-duty world of steel production and wire forming, precision matters just as much as power. Components face abrasive media, thermal stress, and high rotational loads — often under 24/7 operation. Downtime is costly. Accuracy and durability are non-negotiable.

With 20+ years of CNC experience, we deliver precision-machined components for rolling mills, wire drawing machines, straighteners, coil feeders, shearing lines, gearboxes, and take-up systems used across steel, alloy, and metal processing lines.

✔ Machining Challenges in Steel & Wire Equipment Parts

Working with parts that operate under high torque, temperature, wear, and misalignment tolerance brings significant challenges:

- Large & long components: Shafts, rolls, and mandrels up to 2 meters in length require high-straightness and balancing.

- Wear resistance: Surfaces in contact with steel wire or billets must resist abrasion and galling.

- High hardness materials: Carbide inserts, tool steels, and hardened bearing surfaces demand post-heat treat machining.

- Repeatability in harsh environments: Sealing surfaces and bearing fits must be held despite thermal cycles and shock loads.

- Surface finish & geometry: Polished surfaces are essential for guiding wire or rolling steel without damage or scratch.

✔ Key Components We Specialize In

| Component | Application | Features |

|---|---|---|

| Work Rolls & Guide Rolls | Cold/hot rolling lines | OD grinding, dynamic balancing, hardened surface |

| Wire Drawing Dies / Die Holders | Wire pulling lines | Concentricity < 0.01mm, wear-resistant materials |

| Mandrels / Arbors | Slitting, coiling | Hardened and ground, matched to gear shaft systems |

| Straightener Rollers | Wire, rod, or strip lines | Polished to Ra < 0.2μm, multi-groove CNC turning |

| Gear Housings / Transmission Blocks | Steel machinery drive | Surface-milled, flatness < 0.01mm |

| Shear Blades / Slide Plates | Cutting & handling | Tool steel, vacuum heat treat, lapped edge finish |

| Drive Shafts / Couplings | Rolling or feeding systems | Keyed + ground to ±0.005mm, hardened surfaces |

✔ Materials & Treatments We Use

| Material | Use Case | Surface/Heat Treatment |

|---|---|---|

| 42CrMo4 / SCM440 | Rolls, shafts, mandrels | Induction hardened (HRC 55+), ground OD |

| Tool Steel (H13, D2, SKD11) | Blades, guiding tools | Vacuum heat treatment, cryogenic optional |

| Alloy Steel (8620, 20CrMnTi) | Gear shafts, couplings | Carburized + gear grinding |

| Tungsten Carbide / Inlay | Dies, guides | Brazed inserts, finish lapped |

| GCr15 / SUJ2 | Bearings and rotary rings | Through hardened + precision ground |

| Stainless Steel (SUS304, 410) | Corrosion-prone equipment | Polished + passivated |

We also provide chrome plating, nitriding, black oxide, and PTFE or ceramic coatings depending on wear/friction needs.

✔ Equipment Used in Our Production

- 4-axis CNC lathes – For long shafts, rollers, and dies

- Surface & cylindrical grinding machines (OD up to 600mm)

- Horizontal & vertical machining centers (max 2000x1000mm envelope)

- High-speed wire EDM & sinker EDM – For die and blade details

- Dynamic balancing system – For rotating parts at up to 10,000 RPM

- CMM + Profile Projector + Surface Roughness Tester

Optional services include assembly of roll units, die set packaging, and batch replacement kits for maintenance teams.

✔ Global Client Success Stories

- ✅ Roller shaft sets for a Turkish cold-rolling mill (Ø180mm, HRC 60 hardened, runout < 0.01mm)

- ✅ Wire die holders with precision-ground bushings for a Belgian cable machine OEM

- ✅ Mandrel + arbor sets for a U.S.-based coil slitting line integrator

- ✅ Slide guides + shear blades for Indian hot shear retrofit system

✔ Why Global Clients Choose Our CNC Services

- 🏭 Full control over machining + heat treatment + surface finishing

- 🛠 Experience with large steel & wire forming OEM components

- 📄 ISO-compliant quality management, inspection reports included

- 🌐 Delivered to 20+ countries across Europe, Middle East, Asia, and South America

- 🕒 Fast sample turnaround and small-lot flexibility for MRO or prototyping

🧱 Forged in Steel. Machined for Endurance.

From 1-off mandrels to 500-piece roller series, we support your metalforming and steel production lines with robust, precision CNC parts built to last.

📩 Send your drawings and application — we’ll deliver solutions tailored to your system.