Precision Machining Services for Lithium Battery Equipment Components

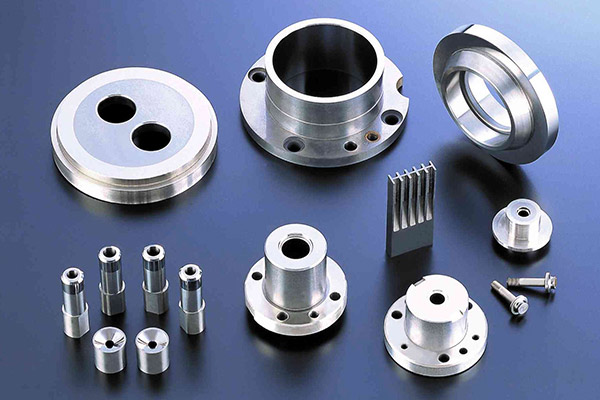

Lithium battery manufacturing equipment relies on highly precise and wear-resistant components to support processes such as electrode coating, cell winding, tab welding, and module assembly. CNC machining plays a critical role in delivering stable, high-precision mechanical parts that ensure continuous and accurate production.

Core Machining Capabilities

- Multi-axis CNC milling and turning for complex structural parts, jigs, fixtures, and housings

- Wire EDM and spark EDM for fine slots, deep grooves, and precise contours

- Surface and cylindrical grinding for guide rails, rollers, and bearing seats

- Deep-hole drilling and high-precision boring for frame and support components

- Assembly hole, tapping, and thread machining for mechanical integration

Materials Processed

- Stainless steel and anti-corrosion steel for long-term chemical resistance

- Aluminum and aluminum alloys for lightweight, precision components

- Tungsten carbide and ceramics for ultra-hard, wear-resistant parts

- Engineering plastics and composites for insulation and non-metallic supports

Commonly Machined Lithium Battery Equipment Parts

- Electrode coating machine guide rails and rollers

- Cell winding mandrels, shafts, and clamps

- Tab welding fixtures and cooling blocks

- Transfer arms, positioning plates, and support brackets

- Module and pack assembly positioning components

- Custom components for pouch, prismatic, and cylindrical cell production

Advantages

- High dimensional accuracy ensures process stability and product consistency

- Wear-resistant materials extend component life in high-speed, repetitive operations

- Lightweight, precision-machined structures improve equipment responsiveness

- Ability to customize according to various battery production line requirements

- Support for both sample development and volume production

SEO Keywords

- CNC machining for lithium battery equipment

- Precision parts for battery cell assembly lines

- Electrode coating machine component machining

- Tab welding fixture CNC manufacturing

- Guide rails and rollers for battery production

- Aluminum parts for lithium battery automation

- Custom brackets for battery pack assembly

- Tungsten carbide wear parts for battery machinery

- High-precision machining for energy storage equipment

- EDM machining for lithium battery tooling