Ultra-Precision Ceramic Components for the Aerospace & Defense Industry

±0.001mm tolerance | High thermal stability | Extreme material reliability for mission-critical systems

In aerospace and defense engineering, material integrity, dimensional precision, and environmental resistance are vital to mission success. From satellites to jet engines to radar systems, technical ceramics are widely used in critical components that must endure extreme temperatures, corrosive atmospheres, rapid acceleration, and long-duration exposure without failure.

At our facility, we specialize in the custom machining of aerospace-grade ceramic components, achieving tolerances as tight as ±0.001mm and supporting international Tier-1 aerospace contractors and defense integrators.

Aerospace-Grade Ceramic Materials

We machine a wide range of technical ceramics including:

- Silicon Nitride (Si₃N₄) – high fracture toughness and thermal shock resistance

- Alumina (Al₂O₃) – stable at 1000°C+, electrically insulating

- Zirconia (ZrO₂) – exceptional strength under mechanical stress

- Macor® machinable glass ceramics – used in low-volume prototypes or space applications

- Boron Nitride, Mullite, and Steatite – used in specialized insulation or structural roles

These materials serve as ideal solutions where metals, polymers, or composites fail due to temperature, weight, or chemical exposure.

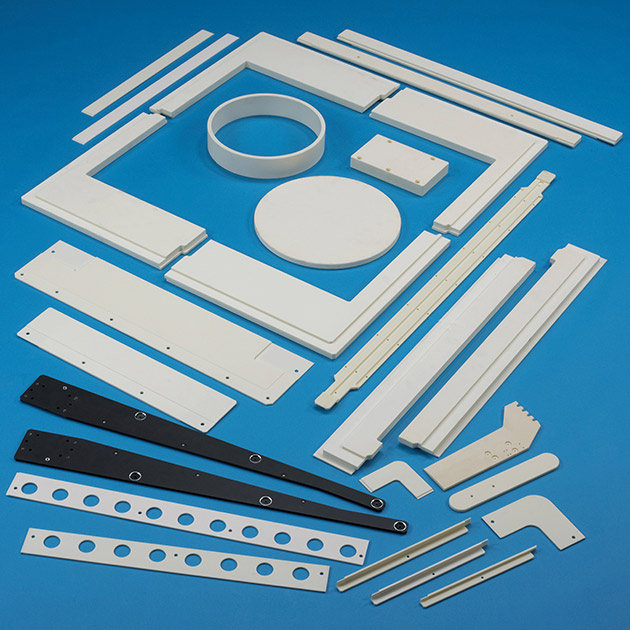

Key Ceramic Components We Manufacture

- Ceramic turbine nozzles and rotors

- Electrically insulating rings and feedthroughs for avionics

- High-frequency radar-transparent ceramic domes

- Thermal barrier plates for exhaust systems

- Laser and optical alignment ceramic mounts

- Plasma-resistant ceramic insulators in propulsion systems

- Lightweight ceramic armor tiles for ballistic protection

Applications include:

✔ Jet engine components

✔ Satellite payloads and electronics

✔ Hypersonic flight systems

✔ UAVs and missile systems

✔ High-voltage defense electronics

Advanced Manufacturing Capabilities

We operate:

- 5-axis high-speed CNC centers for aerodynamic geometries

- Micron-grade cylindrical and profile grinding for sealing and alignment parts

- Roundness, flatness, and concentricity inspection systems

- Cleanroom-level cleaning and packaging for electronic and satellite use

Performance Highlights:

- Dimensional tolerance: ±0.001mm

- Geometric tolerance: ≤0.002mm

- Surface finish: up to Ra 0.02μm for critical sealing or optical contact surfaces

Engineering Support for Critical Missions

We work directly with aerospace engineers and defense R&D teams to:

- Review 3D models and drawings for manufacturability

- Provide material certification and traceability for aerospace compliance

- Support DFMA for ceramic-to-metal or hybrid assemblies

- Deliver inspection reports (FAI, CMM, batch CoC) according to AS9100/ISO9001 workflows

Whether it’s flight hardware, test components, or prototype validation, we ensure all ceramic parts meet the highest standards of performance and documentation.

Global Project Experience

We’ve delivered aerospace ceramic components for programs involving:

- European satellite thermal shielding systems

- US missile insulation housings

- Jet engine prototype turbine flow components

- High-vacuum ceramic insulators for space-grade electronics

- Hypersonic platform development in Asia-Pacific

We are trusted by aerospace system integrators and advanced materials labs for our ability to deliver mission-critical precision under pressure.

Ceramic Precision Built for the Sky—and Beyond

From atmosphere to orbit, from ground control to combat zones, ceramic parts we produce play vital roles in the most advanced technologies on Earth. We welcome the opportunity to collaborate with aerospace and defense innovators who demand the highest levels of precision, durability, and trust.