Ultra-Precision Machining in the Optics Industry: Elevating Photonic Performance

The optics industry demands an extraordinary level of precision—often at the sub-micron or even nanometer scale. From laser components to advanced lens housings, the performance of optical systems hinges on ultra-smooth surfaces, accurate geometries, and flawless material interfaces.

Challenges in Optical Component Machining

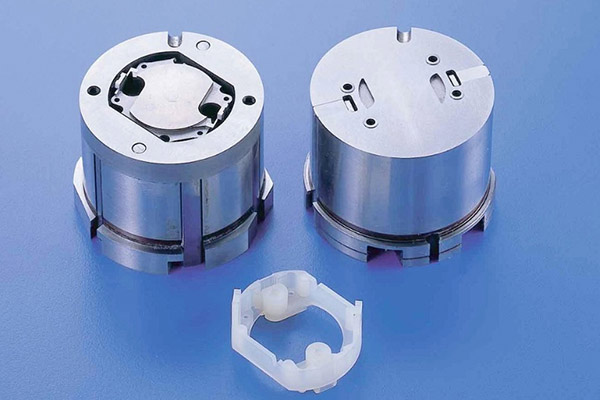

Machining optical components poses unique challenges. Tolerances must be within ±0.001mm, with surface roughness as low as Ra0.005μm. Components like collimators, fiber optic ferrules, and laser reflectors require perfect concentricity, minimal form deviation, and no micro-burrs that could interfere with light transmission or reflection.

Material Complexity and Innovation

Materials used in optical devices are often brittle or hard-to-machine: fused silica, BK7 glass, sapphire, Zerodur®, ceramics, and optical-grade metals like aluminum 6061-T6 and titanium. Each material demands unique tool paths, cutting fluids, and speeds to prevent micro-cracking or surface burning.

Advanced Process Control for Nanometric Precision

Our facility employs 5-axis ultra-precision CNC machining, diamond turning, and fine grinding techniques. Real-time temperature control ensures dimensional stability, while air-floating linear guides minimize vibration during sub-micron movements. Surface finishing techniques such as magnetorheological polishing (MRF) and ion beam figuring (IBF) further enhance accuracy and clarity.

Metrology: Precision Beyond Sight

We utilize white-light interferometers, Zeiss CMMs with sub-micron probes, and atomic force microscopy (AFM) to verify every detail. All lens holders and optical bases are tested for flatness, parallelism, and axis alignment to ensure seamless integration into photonics systems.

Global Application Cases

- Custom sapphire windows for German aerospace lidar systems

- Zerodur mounting frames for EUV lithography machines in the Netherlands

- Fiber connector ferrules for American quantum communication platforms

- Micro-optical stage components used in Japanese automated metrology devices

With our expertise in machining brittle, transparent, and thermal-sensitive materials to optical-grade precision, we empower the next generation of photonic and vision-based technologies.