Why Global Industries Choose China for High Precision Custom Machining — A Strategic Perspective from a Leading Chinese Manufacturer

In the era of global industrial transformation, sectors such as aerospace, medical devices, industrial automation, and marine engineering are demanding increasingly higher precision, complexity, and customization from their mechanical components. As one of the world’s most dynamic precision manufacturing hubs, China has emerged as a trusted partner for global OEMs and engineering firms — not just for cost advantages, but for its deep-rooted capabilities in custom CNC machining, engineering collaboration, and integrated supply chain performance.

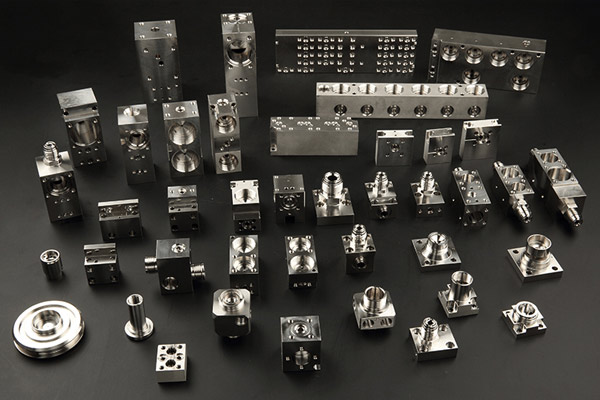

1. Engineering-to-Order: Advanced Custom Machining Based on Drawings

Chinese manufacturers, especially those with over a decade of deep industry involvement, are no longer simple contract producers — they are engineering-driven solution providers. With a strong focus on “machining based on client drawings,” companies can:

- Handle complex geometries and tight tolerances (±0.001 mm)

- Offer multi-axis CNC machining (3, 4, and 5-axis) for intricate contours

- Support small batch prototyping to large-scale production with flexibility

This drawing-based customization aligns perfectly with the demands of aerospace engine housings, surgical tool components, underwater connectors, and more.

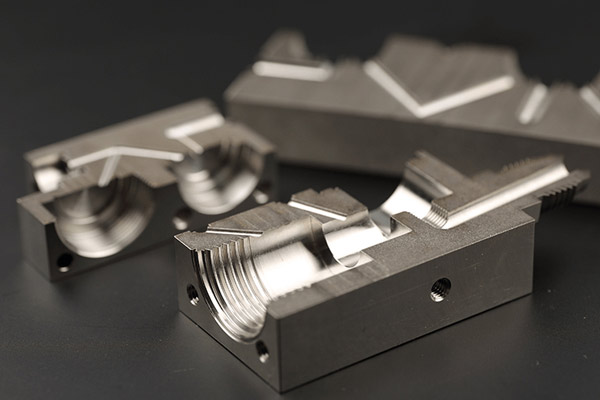

2. Materials Mastery: From Superalloys to Ceramics

Another key advantage lies in China’s material versatility and sourcing integration. Many manufacturers have developed the capability to machine:

- Titanium alloys for aerospace and medical implants

- Stainless steel and aluminum for marine and automation systems

- Engineering plastics and ceramics for insulating, lightweight, or biocompatible applications

- Hard metals and carbides for high-wear tooling and hydraulic systems

With stable access to domestic and international raw material supply chains, lead times and quality remain well-managed — even for exotic or demanding alloys.

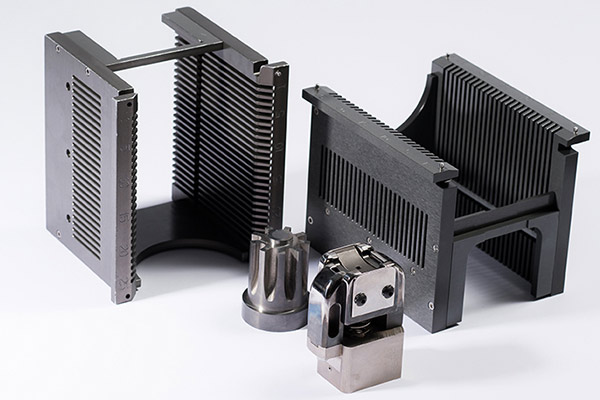

3. Nearly 20 Years of Industry Experience: Craft Meets Technology

Chinese precision machining firms, especially those with 15–20 years of history, have accumulated unparalleled process knowledge across multiple industries. This depth of experience means:

- Proven know-how in thermal distortion control, form & position tolerance, and surface integrity

- Expert use of Swiss-style lathes, micron-level grinders, and coordinate measuring machines (CMMs)

- Consistent ISO9001, IATF16949, or AS9100 certifications to meet global compliance requirements

The combination of mature process control and skilled workforce ensures that parts not only meet spec — they enhance the final product’s reliability and performance.

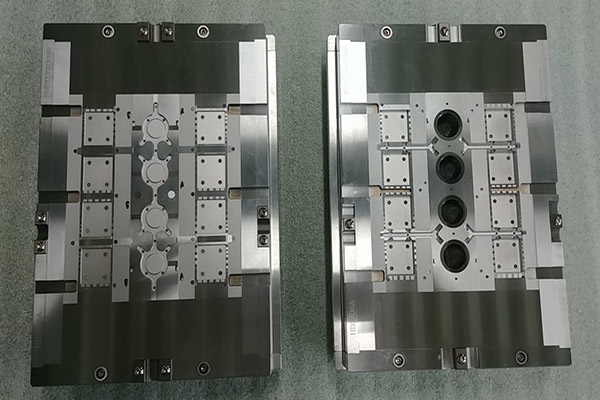

4. Collaborative Engineering: From Quote to Final Inspection

Unlike the old “build-to-print” model, today’s leading Chinese manufacturers engage in real-time technical communication with international engineering teams:

- DFM (Design for Manufacturability) feedback provided at early stages

- Iterative collaboration using CAD/CAM integration, 3D simulation, and live review sessions

- Flexibility to implement design changes during prototyping or pilot runs

This model is especially critical in fields like medical robotics, offshore power connectors, or aerospace suspension systems where engineering agility is vital.

5. On-Time Delivery with Global Logistics Integration

Chinese factories have significantly improved in delivery reliability, aided by:

- Lean production scheduling and ERP-integrated order tracking

- Close relationships with global freight partners (DHL, FedEx, sea-air multimodal routes)

- Custom packaging, traceability documentation, and support for dual sourcing strategies

Whether it’s a just-in-time shipment for a European automation plant or urgent parts for a North American surgical OEM, Chinese suppliers are increasingly meeting — and exceeding — delivery commitments.

Conclusion: China’s Strategic Role in Global Precision Manufacturing

The future of precision manufacturing is customized, material-intensive, and collaboration-centric. Chinese high-precision machining manufacturers, with their deep machining expertise, robust material capabilities, and proactive engineering support, are positioned not just as suppliers — but as global partners in innovation.

From aerospace to automation, marine to medical — the world builds with China, because China builds with precision.