Why Global Powertrain & Engine Manufacturers Choose China for Precision Component Machining

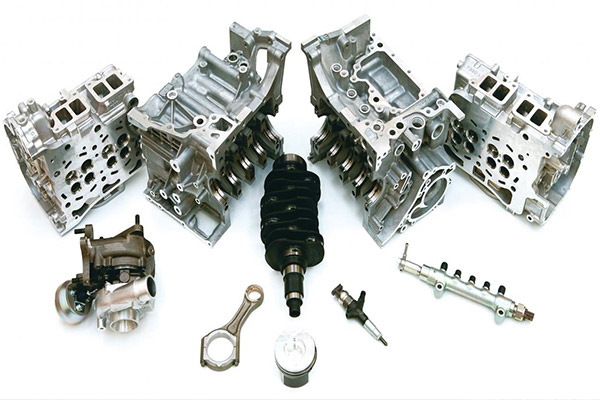

In the global manufacturing landscape, powertrain and engine systems stand as some of the most demanding fields in terms of component precision, mechanical integrity, and long-term performance. These systems form the core of everything from high-performance vehicles and industrial machines to aerospace engines and marine drives.

As one of the world’s leading hubs for precision CNC machining, China is playing a pivotal role in helping global manufacturers innovate, optimize, and scale production — especially in high-load, high-speed, and high-reliability applications.

✅ 1. Deep Engineering Collaboration from the Design Stage

Unlike traditional machining models based on passive build-to-print services, today’s leading Chinese manufacturers engage in early-stage collaboration with global design engineers. This includes:

- Technical reviews of 2D/3D CAD drawings

- Tolerance stack-up and functional feasibility analysis

- Suggestions on Design for Machining (DFM) and cost optimization

This close communication ensures that every gear shaft, cam, or coupling component not only meets specs — it contributes to the overall system performance, especially in transmission, crankshaft, or turbocharger assemblies.

✅ Real-world Example: A European engine manufacturer improved assembly fit by 40% through co-engineered tolerance refinements with a Chinese precision shop.

🔩 2. Advanced Custom CNC Machining Based on Drawings

Transmission and engine components demand tight tolerances, multi-axis complexity, and specialty surfaces. Chinese CNC shops today deliver on this with:

- ±0.001mm tolerance control using precision grinders, lathes, and multi-axis machining centers

- Process simulation and CAM path optimization for gear profiles, crank contours, and deep bores

- Batch consistency for high-volume parts like gear shafts, cam lobes, bearing housings, and more

Whether producing one-off prototypes or mass-production runs, this capacity for custom machining ensures compatibility with global engine standards, including DIN, JIS, and ISO.

🧱 3. Strategic Material Sourcing and In-House Expertise

The performance of engine and transmission components is heavily dependent on material properties: fatigue resistance, thermal stability, and surface hardness. Leading Chinese shops provide:

- Material traceability from domestic and imported steel mills

- Expertise in machining materials like alloy steel (42CrMo, 20CrMnTi), stainless steel, ductile iron, and case-hardened materials

- In-house or partnered services for heat treatment, nitriding, carburizing, etc.

This integrated material-management capability ensures both performance and cost-efficiency.

⚙️ 4. Two Decades of Precision Machining Experience

With nearly 20 years of specialization, many Chinese manufacturers have:

- Refined high-load transmission part production processes

- Developed mature control of concentricity, roundness, gear meshing accuracy, and surface roughness (Ra 0.2~0.05μm)

- Mastered machining sequences for crankshafts, flywheels, camshafts, etc.

Such know-how is invaluable in minimizing internal losses in engines, improving torque transfer, and prolonging part lifespan.

📦 5. Reliable On-Time Delivery with Global Support

The success of transmission and engine programs relies heavily on supply chain stability and lead time control. Chinese suppliers today are fully equipped with:

- ERP-based production tracking systems

- Flexible production cells for urgent orders

- Strategic partnerships with DHL, FedEx, and global freight forwarders

- Support for PPAP, FAI, and full traceability documentation

From Europe to North America, many customers now rely on Chinese partners as Tier 2 and Tier 3 suppliers within their global production ecosystems.

✅ Conclusion: Why China is Powering the World’s Powertrain Systems

In an industry where precision, durability, and integration matter most, Chinese precision machining suppliers bring together:

🔧 Co-engineering capabilities

🧱 Material & process mastery

📏 Unmatched precision control

🚚 Global delivery reliability

From planetary gear carriers to high-speed shafts and turbo engine components, China isn’t just catching up — it’s driving the evolution of powertrain precision manufacturing.